Nano-network structural carbon material with carbon nanotube core@functional amorphous carbon shell unit and preparation method and application thereof

A carbon nanotube and amorphous carbon technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of lack of hierarchical design, lack of high functional groups, unfavorable high functionality and high performance, etc. , to achieve the effect of synchronizing crosslinking and carbonization and avoiding liquid phase crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

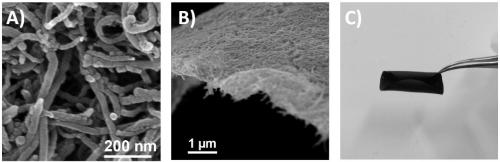

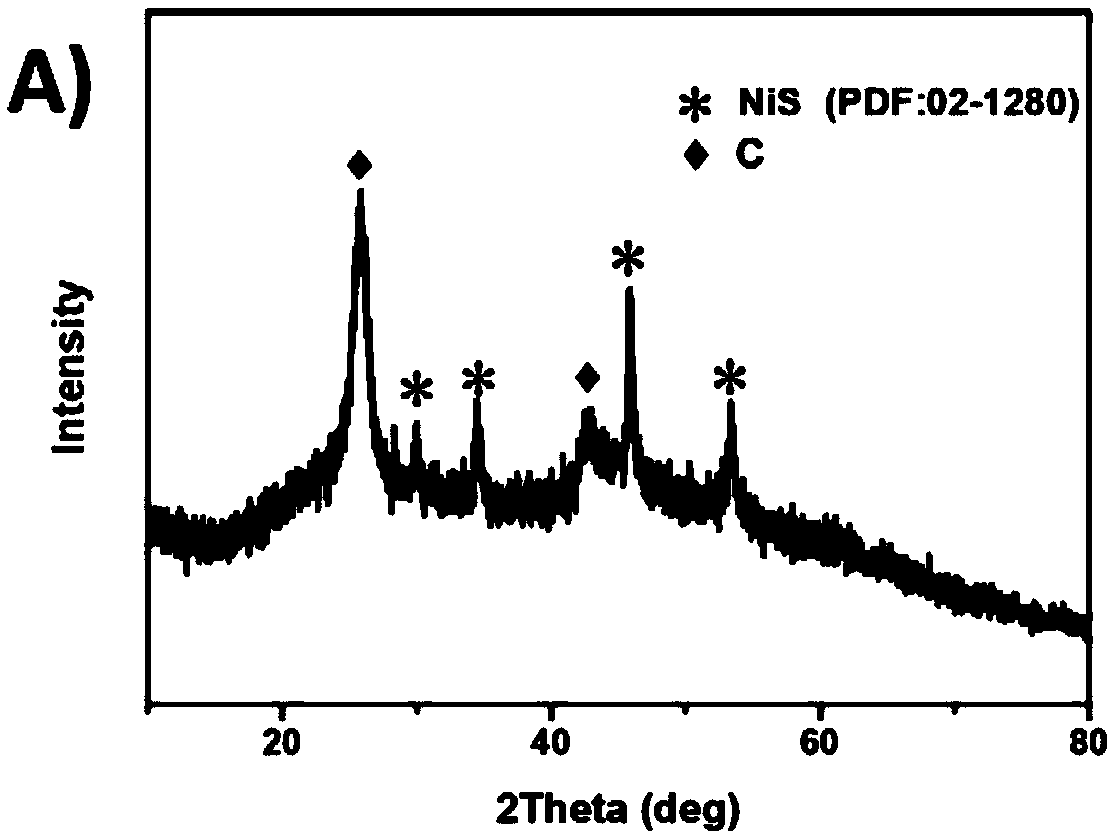

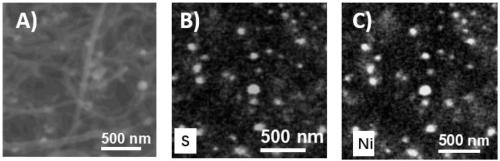

[0054] The embodiment of the present invention provides a method for preparing a carbon nano-network structure carbon material with a carbon nanotube core@functional amorphous carbon shell unit, comprising the following steps:

[0055] (1) Modified carbon nanotubes (CNTs) with bromine groups to obtain carbon nanotubes with bromine functional groups (CNT-Br): add 174mL of nitric acid and 21mL of water to 5.7g of CNTs, sonicate for 30min, and reflux at 120°C for 24h , filtered and washed three times with water, vacuum dried overnight at 90°C to obtain CNT-COOH; add 60 mL of thionyl chloride to the obtained CNT-COOH, react at 70°C for 24 hours to obtain CNT-COCl, and then remove excess chlorine by vacuum treatment sulfoxide; add 120mL of anhydrous ethylene glycol, stir at 120°C for 48h, filter the solid and wash it three times with tetrahydrofuran, and obtain CNT-OH after vacuum drying; take 2.8g of CNT-OH, 70mL of chloroform, 0.2g of 4-dimethyl Put aminopyridine and 3mL triethyl...

Embodiment 2

[0066] The embodiment of the present invention provides a method for preparing a carbon nano-network structure carbon material with a carbon nanotube core@functional amorphous carbon shell unit, comprising the following steps:

[0067] (1) Modification of carbon nanotubes (CNTs) with bromine groups to obtain carbon nanotubes with bromine functional groups (CNT-Br): Add 170mL of nitric acid and 17mL of water to 5.7g of CNTs, sonicate for 30min, and reflux at 110°C for 24h , filtered and washed three times with water, vacuum dried overnight at 90°C to obtain CNT-COOH; add 55mL of thionyl chloride to the obtained CNT-COOH, react at 60°C for 24h to obtain CNT-COCl, and then remove excess chlorine by vacuum treatment sulfoxide; add 110mL of anhydrous ethylene glycol, stir at 100°C for 50h, filter the solid and wash it three times with tetrahydrofuran, and dry it in vacuo to obtain CNT-OH; take 2.8gCNT-OH, 65mL chloroform, 0.18g 4-dimethylamino Put pyridine and 2.8mL triethylamine i...

Embodiment 3

[0072] The embodiment of the present invention provides a method for preparing a carbon nano-network structure carbon material with a carbon nanotube core@functional amorphous carbon shell unit, comprising the following steps:

[0073] (1) Modification of carbon nanotubes (CNTs) with bromine groups to obtain carbon nanotubes with bromine functional groups (CNT-Br): add 180mL of nitric acid and 25mL of water to 5.7g of CNTs, sonicate for 30min, and reflux at 130°C for 24h , filtered and washed three times with water, vacuum dried overnight at 90°C to obtain CNT-COOH; add 65mL of thionyl chloride to the obtained CNT-COOH, react at 80°C for 20h to obtain CNT-COCl, and then remove excess chlorine by vacuum treatment sulfoxide; add 130mL of anhydrous ethylene glycol, stir at 120°C for 46h, filter the solid and wash with THF three times, and dry in vacuo to obtain CNT-OH; take 2.8g of CNT-OH, 75mL of chloroform, and 0.22g of 4-dimethyl Aminopyridine and 3.2mL triethylamine were plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com