Preparation method for resistant starch

A technology for resistant starch and starch, applied in the field of preparation of resistant starch, can solve the problem that the content of resistant starch is not very high, and achieve the effects of excellent physiological function, good thermal stability and reduced swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

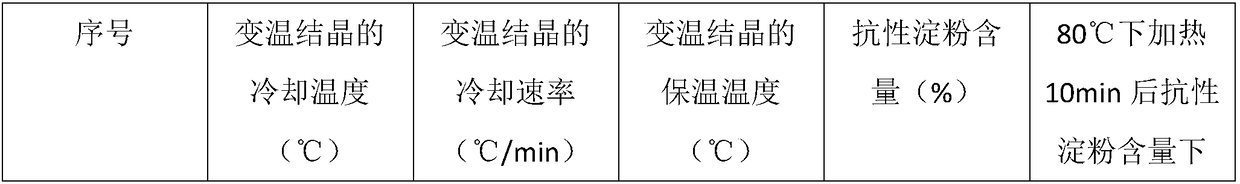

[0023] Weigh an appropriate amount of rice starch passing through a 100-mesh sieve, and use deionized water to make starch milk with a solid content of 8%, so as to ensure that the starch granules are evenly distributed therein. Then gelatinize at 75°C for 20min, cool to 55°C, add 50 ASPU / g (based on dry weight of starch) pullulanase to debranch at 50°C for 10h, and use a rotary evaporator at 40°C after the debranching is completed Carry out concentration treatment, make its solid content reach 30%. Add stearic acid as an auxiliary agent and react at 90°C for 20 minutes. The debranched starch that has completed the complexation reaction is immediately placed in a -80°C refrigerator for rapid cooling for 1 minute at a cooling rate of 18°C / min, and then placed in a 40°C water bath for 20 minutes. . Finally, the heat-preserved sample was dried with hot air at 40°C, crushed, and passed through a 100-mesh sieve.

[0024] The content of resistant starch measured by Englyst method ...

Embodiment 2

[0026] Weigh an appropriate amount of rice starch that has passed through a 100-mesh sieve, and use deionized water to make starch milk with a solid content of 10%, so as to ensure that the starch granules are evenly distributed therein. Then gelatinize at 85°C for 20min, cool to 65°C, add 70 ASPU / g (based on dry weight of starch) pullulanase to debranch at 60°C for 8h, and use a rotary evaporator at 45°C after the debranching is completed Carry out concentration treatment, make its solid content reach 40%. The additive oleic acid was added and reacted at 100°C for 30 minutes. The debranched starch that completed the complexation reaction was immediately placed in a 4°C refrigerator for rapid cooling for 5 minutes at a cooling rate of 12°C / min, and then placed in a 50°C water bath for 20 minutes. Finally, the heat-preserved samples were dried with hot air at 50°C, pulverized, and passed through a 100-mesh sieve.

[0027] The content of resistant starch measured by Englyst met...

Embodiment 3

[0029] Weigh an appropriate amount of rice starch that has passed through a 100-mesh sieve, and use deionized water to prepare starch milk with a solid content of 9%, to ensure that the starch granules are evenly distributed therein. Then gelatinize at 80°C for 20min, cool to 60°C, add 65 ASPU / g (based on starch dry basis weight) of pullulanase to debranch at 55°C for 9h, and use a rotary evaporator at 43°C after the debranching is completed Carry out concentration treatment, make its solid content reach 35%. Add palmitic acid as an auxiliary agent and react at 95°C for 25 minutes. The debranched starch that has completed the complexation reaction is immediately placed in a refrigerator at -18°C for 3 minutes, and the cooling rate is 15°C / min, and then placed in a water bath at 45°C for 20 minutes. . Finally, the heat-preserved sample was dried with hot air at 45°C, crushed, and passed through a 100-mesh sieve.

[0030] The content of resistant starch measured by Englyst met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com