A kind of high-efficiency gasoline detergent and preparation method thereof

A gasoline detergent and high-efficiency technology, applied in the field of high-efficiency gasoline detergent and its preparation, can solve the problems of inability to reduce fuel consumption, engine wear, poor cleaning and carbon removal effects, etc., and achieve thermal stability, oxidation resistance, and steric hindrance The effect of increasing and decreasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

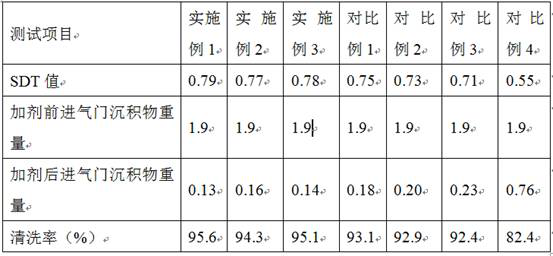

Examples

preparation example Construction

[0027] The preparation method of catalytic active agent is:

[0028] Take zirconium oxychloride and add deionized water according to the mass ratio of 1~3:8~10, add polyethylene glycol-400 with 10~30% deionized water quality, stir and mix at 30~50°C for 30~40min to obtain the mixture , take the mixture according to the mass ratio of 10~20:2~5, add tungsten phosphate, add 15~25% of the mixture mass fraction and 25% ammonia water, let it stand for 1~3h, suction filter, take the suction filter residue and dry it to get the dried product , Take the dried material and bake it at 400~600°C for 2~5h, and cool to room temperature to obtain the catalytic active agent.

[0029] The borate additive is: take triethanolamine borate and mix it with boric acid diglyceryl stearate and tributoxyborane at a mass ratio of 1~3:2~6:2~4.

[0030] The preparation method of detergent active additive is:

[0031] (1) Take isobutene and add n-hexane and toluene at a mass ratio of 1~4:5~7:2~5 to mix, ...

Embodiment 1

[0040] The preparation method of catalytic active agent is:

[0041] Take zirconium oxychloride and add deionized water at a mass ratio of 1:8, add polyethylene glycol-400 with 10% deionized water quality, stir and mix at 30°C for 30 minutes to obtain a mixture, take the mixture and add at a mass ratio of 10:2 For tungsten phosphate, add 15% of the mixture with ammonia water with a mass fraction of 25%, let it stand for 1 hour, filter it with suction, take the filter residue and dry it to obtain a dry product, take the dry product and roast it at 400°C for 2 hours, and cool it to room temperature to obtain catalytic activity agent.

[0042] The boric acid ester additive is: take triethanolamine boric acid ester, add boric acid diglyceryl stearate and tributoxy borane in a mass ratio of 1:2:2 and mix it.

[0043] The preparation method of detergent active additive is:

[0044] (1) Take isobutene and add n-hexane and toluene at a mass ratio of 1:5:2 to mix, stir and mix at 1°C...

Embodiment 2

[0053] The preparation method of catalytic active agent is:

[0054] Take zirconium oxychloride and add deionized water at a mass ratio of 2:9, add polyethylene glycol-400 with 20% deionized water quality, stir and mix at 40°C for 35 minutes to obtain a mixture, take the mixture and add it at a mass ratio of 15:3 For tungsten phosphate, add 20% of the mixture with ammonia water with a mass fraction of 25%, let it stand for 2 hours, filter it with suction, take the suction filter residue and dry it to obtain a dry product, take the dry product and roast it at 500°C for 3 hours, and cool it to room temperature to obtain the catalytic activity agent.

[0055] The boric acid ester additive is: take triethanolamine boric acid ester and mix it with boric acid diglyceryl stearate and tributoxy borane in a mass ratio of 2:4:3.

[0056] The preparation method of detergent active additive is:

[0057] (1) Take isobutene and add n-hexane and toluene at a mass ratio of 2:6:3 to mix, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com