Method for extracting lead from waste CRT one glass

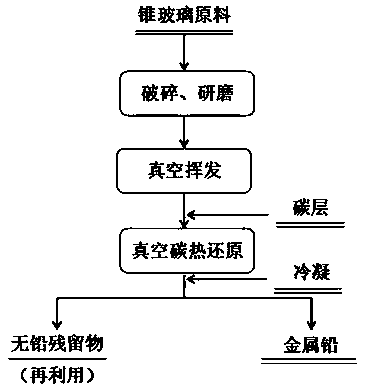

A technology of cone glass and lead oxide, applied in the field of comprehensive recovery of secondary resources, can solve the problems of immature comprehensive recovery and utilization of secondary resources, low lead extraction rate, low lead recovery rate, etc., and achieve environmental protection and labor health, pollution avoidance, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

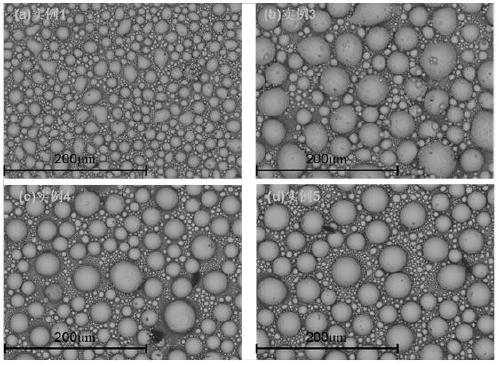

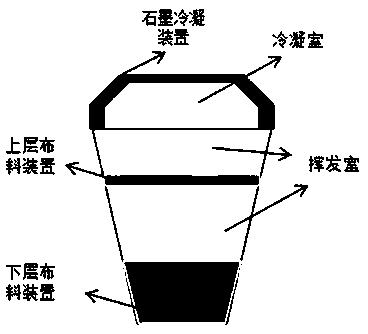

Embodiment 1

[0026] First, clean the surface of the conical glass, and use a jaw crusher to break the large conical glass into a block of conical glass (50g, of which the content of lead oxide is 28.54%) suitable for vacuum furnace; the granular carbonaceous reducing agent is placed on the upper layer of the vacuum furnace The device is used for carbothermal reduction reaction, and the carbon content in the carbonaceous reducing agent is 5g, and the cone glass is placed in the lower distributing device; for vacuum carbothermal reduction treatment, the temperature is raised to 1150°C, and the heating rate is 5°C / min. The state pressure is in the range of 5~8Pa, heat preservation for 30min, and the room temperature is naturally cooled by the furnace body, and the metal lead is obtained in the condensation pan, and the residual glass after removing lead oxide is obtained in the volatilization chamber.

[0027] The recovery rate of metallic lead was 43.34% by X-ray fluorescence spectrometer ana...

Embodiment 2

[0029] First, clean the surface of the conical glass, and use a jaw crusher to break the large conical glass into a block of conical glass (50g, of which the content of lead oxide is 28.54%) suitable for vacuum furnace; the granular carbonaceous reducing agent is placed on the upper layer of the vacuum furnace The device is used for carbothermal reduction reaction and the carbon content in the carbonaceous reducing agent is 15g. The cone glass is placed in the lower distributing device; vacuum carbothermal reduction treatment is carried out, and the temperature is raised to 1300°C with a heating rate of 10°C / min. In the range of pressure less than 10Pa, keep warm for 30 minutes, cool the room temperature naturally through the furnace body, get metal lead in the condensation tray, and get the residual glass after removing lead oxide in the volatilization chamber.

[0030] The elemental content of the residue was analyzed by X-ray fluorescence spectrometer to obtain the removal r...

Embodiment 3

[0032] First, clean the surface of the conical glass, and use a jaw crusher to break the large conical glass into a block of conical glass (50g, of which the content of lead oxide is 28.54%) suitable for vacuum furnace; the granular carbonaceous reducing agent is placed on the upper layer of the vacuum furnace The device is used for carbothermal reduction reaction and the carbon content in the carbonaceous reducing agent is 20g. The conical glass is placed in the lower distributing device; vacuum carbothermal reduction treatment is carried out, and the temperature is raised to 1400°C with a heating rate of 20°C / min. The pressure is in the range of 10~15Pa, heat preservation for 30min, the room temperature is naturally cooled by the furnace body, the metal lead is obtained in the condensation pan, and the residual glass after removing lead oxide is obtained in the volatilization chamber.

[0033] The elemental content of the residue was analyzed by X-ray fluorescence spectromete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com