Method for preparing TiCN coating on surface of screw tap

A technology for coating and taps, which is applied in the field of preparing TiCN coatings on the surface of taps, which can solve the problems of tapping tap thread speed, tap wear, unsuitable for tap surface coating, and large cutting thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] This embodiment provides a method for preparing a TiCN coating on the surface of a tap. It should be noted that the TiCN coating prepared on the surface of the tap of the present invention can be prepared at any high speed. The cutting tool made of steel material is not limited to this example.

[0040] The method for preparing TiCN coating on the surface of the tap provided in this embodiment, its specific preparation process is:

[0041] (1) Use taps (material: W18Cr4V) with a hardness of HRC=60 after quenching at 1170°C and tempering at 550°C as samples, and first perform pretreatment, that is, after surface degreasing and polishing, immerse in acetone for ultrasonic cleaning, alcohol Dehydrate and set aside.

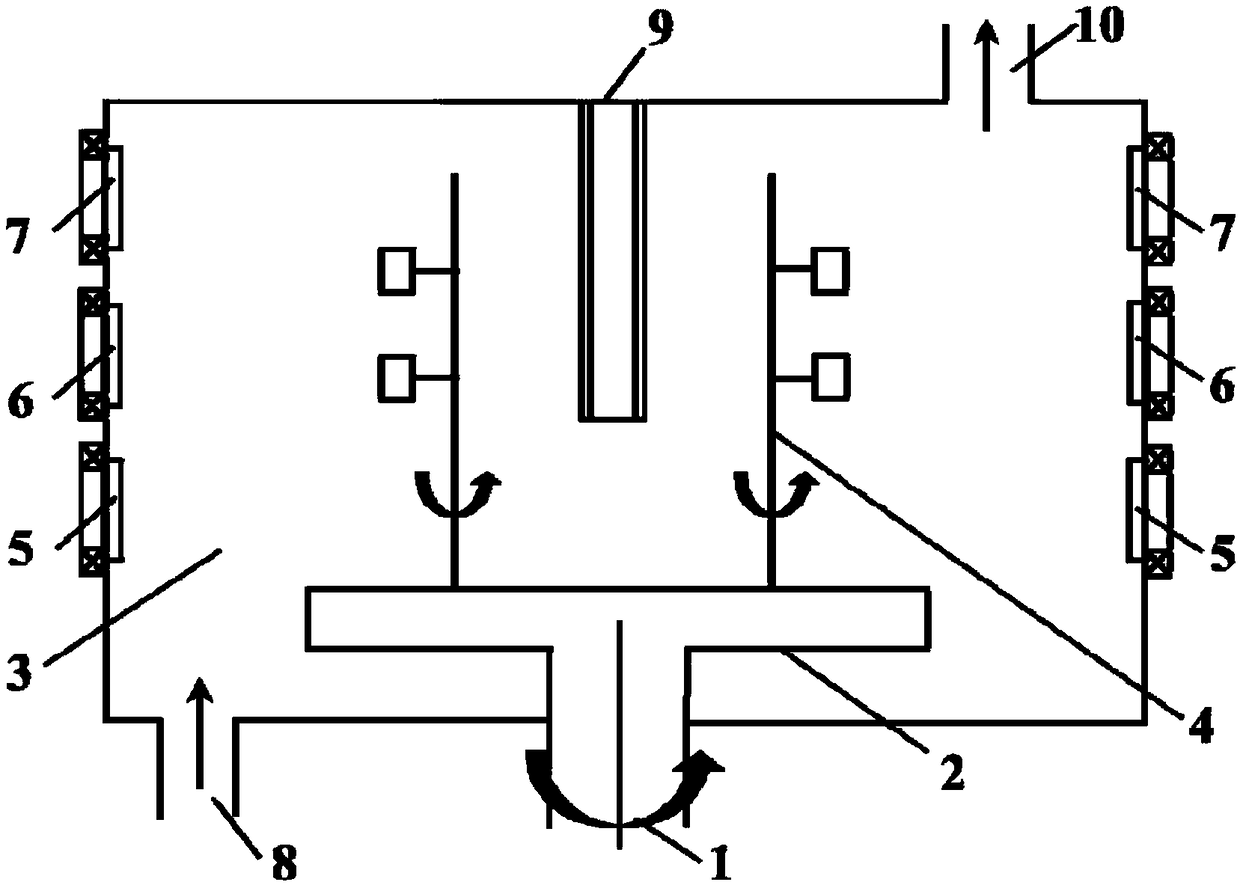

[0042] (2) Put the pretreated sample into the arc ion coating equipment. Such as figure 1 As shown, the arc ion coating equipment at least includes an external power supply bias 1, a turntable 2, a vacuum chamber 3, a turntable rod 4, Ti targets (5, 6, 7), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com