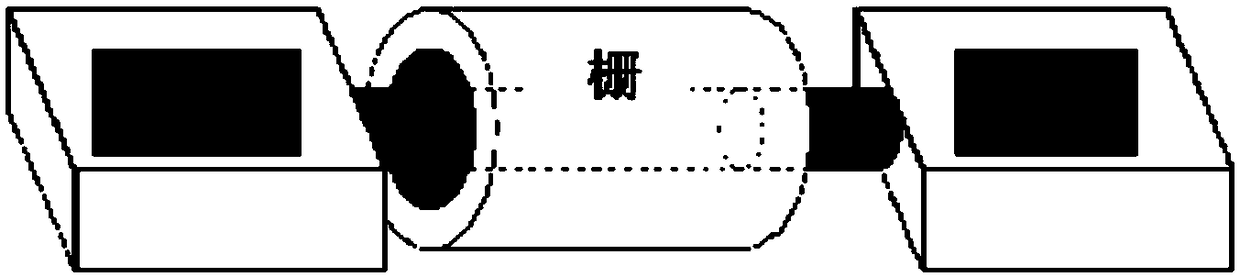

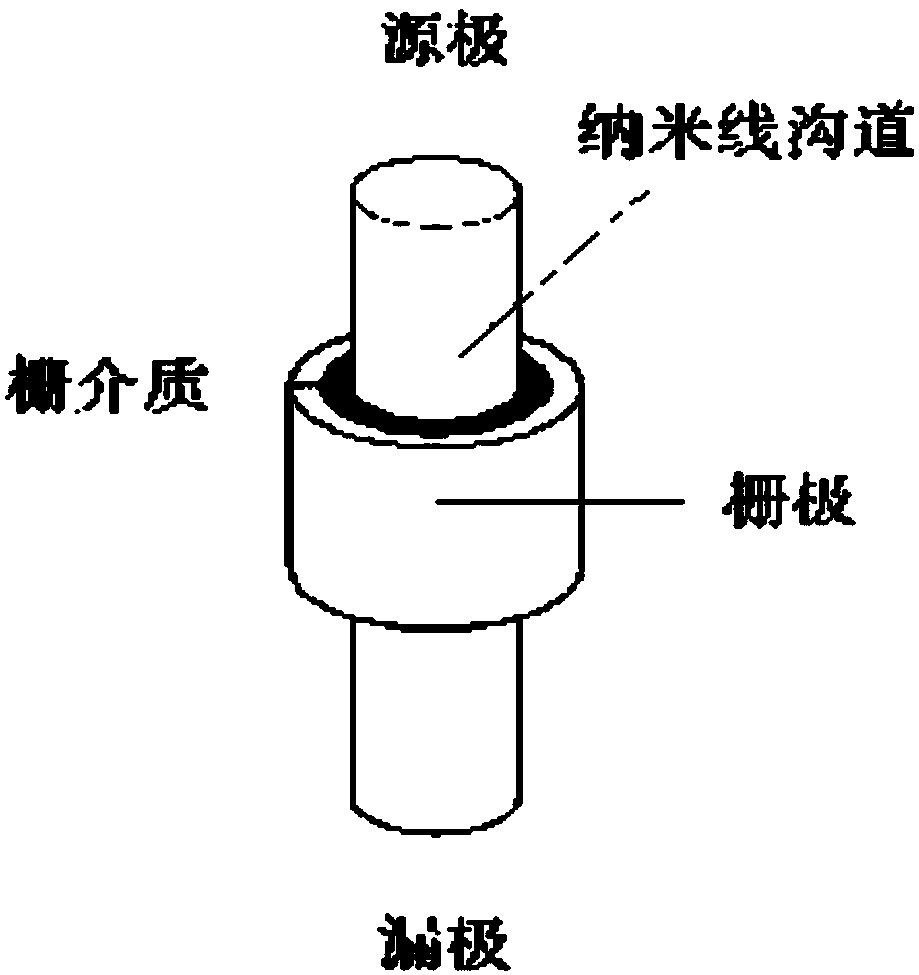

A manufacturing process of a vertical silicon nanowire transistor

A technology of silicon nanowires and manufacturing processes, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as device structure and characteristic asymmetry, and achieve the effect of symmetrical structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0049] Embodiment 2 is used to manufacture flash storage unit devices, and the dose of ion implantation required for the process flow is at 10 16 / cm 2 the following:

[0050] The only difference from Example 1 is that the gate dielectric SiO in Example 1 2 Replaced with the ONO layer used for charge storage in flash memory cells. In step c and step d of embodiment 1, the process step of silicon pillar thermal oxidation is omitted, and the first dielectric layer (SiO 2 ) after the formation of chemical vapor deposition ONO layer (SiO 2 -Si 3 N 4 -SiO 2 ) gate dielectric 710 and polysilicon gate 810, such as Figure 12 and Figure 13 shown. The top polysilicon and top ONO layer are then etched away. The rest of the process flow is the same as that of Embodiment 1, so that the flash memory with the vertical silicon nanowire transistor as the storage unit can be manufactured.

Embodiment 1

[0051] The dose of ion implantation required for the process flow of embodiment 1 and embodiment 2 is at 10 16 / cm 2 Below, if the dose of ion implantation exceeds 10 16 / cm 2 , silicon, polysilicon, SiO 2 If the structure of the dielectric layer is destroyed by the implanted ions, the cases of Embodiment 3 and Embodiment 4 apply, and ion implantation will not be used as a doping method.

Embodiment 3

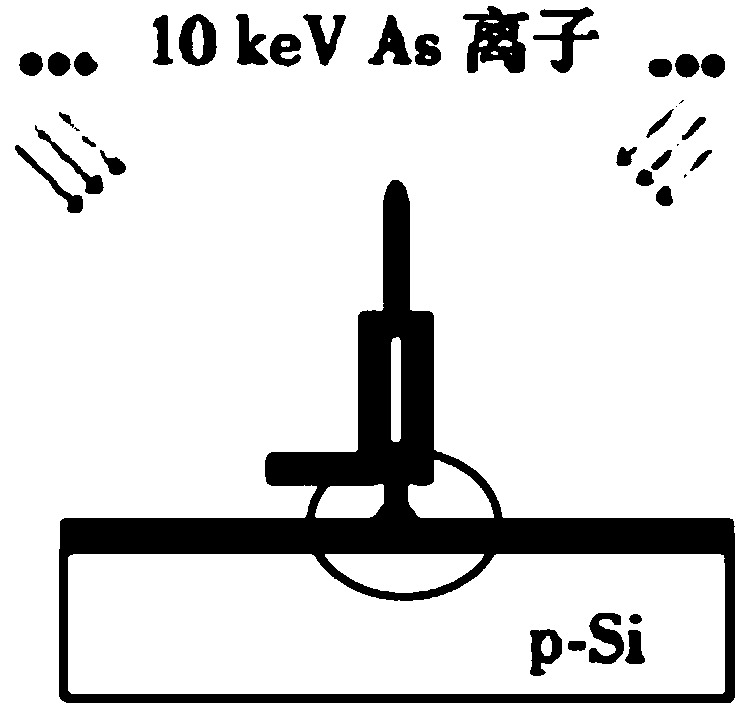

[0052] Embodiment 3 is used to manufacture logic MOSFET devices, and the dose of ion implantation required for the process flow is at 10 16 / cm 2 above:

[0053] At this time, due to the large dose of ion implantation, silicon, polysilicon, SiO 2 The structure of the dielectric layer is damaged, so ion implantation is not used as a doping method, and in-situ doping technology will be used for impurity doping during chemical vapor deposition. In-situ doping reduces an ion implantation process and can achieve uniform doping.

[0054] Specifically, in the first step of the process in step a, instead of using ion implantation for doping, a dopant gas, such as AsH 3 ,PH 3 , B 2 h 6 When the gas is fed into the reaction chamber, the doping of arsenic, phosphorus, boron and other impurities in the epitaxy can be realized. In this embodiment, PH is introduced into the vapor phase epitaxy reaction chamber of silicon 3 and SiH 4 , the doping of phosphorus is carried out by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com