A method of adding a sintering aid to prepare a flexible thermoelectric thick film material with excellent electrical transport properties

A technology of thermoelectric materials and sintering aids, which is applied in the manufacture/processing of thermoelectric devices, etc., can solve the problems of not being able to fully meet the requirements of thermoelectric refrigeration devices, the degradation of thermoelectric thick film electrical properties, and the hindrance of carrier transport. The method is simple and controllable, the electrical transport performance is improved, and the preparation cycle is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

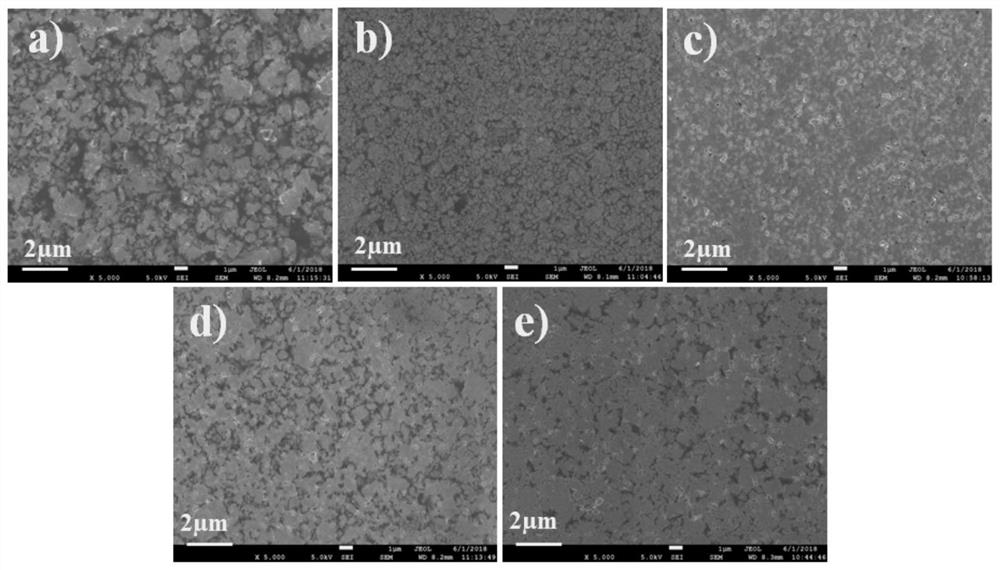

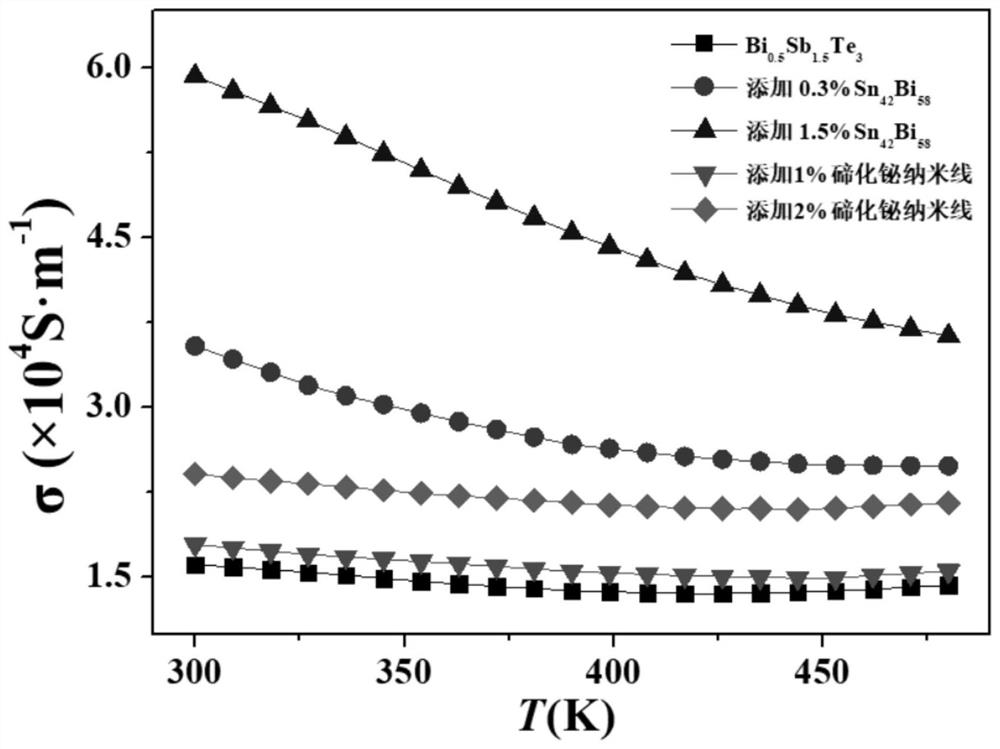

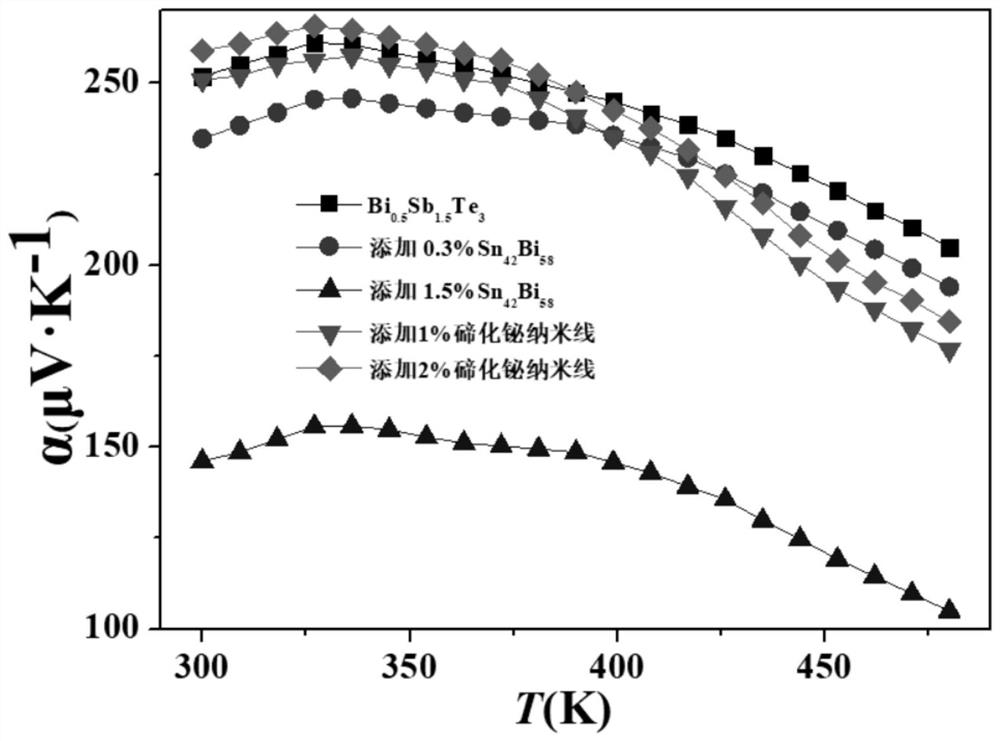

[0030] Add 0.3wt% Sn 42 Bi 58 Preparation of Bi by sintering aid 0.5 Sb 1.5 Te 3 Based thermoelectric composite thick film, comprising the following steps:

[0031] 1) the p-type Bi 0.5 Sb 1.5 Te 3 The ingot is broken, ground, and passed through a 120-mesh sieve to obtain a ready-to-use powder with a particle size of less than 120 μm;

[0032] 2) Calculate and weigh the above Bi according to the mass percentage 0.5 Sb 1.5 Te 3 Powder 9.97g and sintering aid Sn 42 Bi 58 Add 0.03g of alloy powder into a high-energy ball mill tank with a ball-to-material ratio of 55:1, add 50ml of absolute ethanol as a ball mill medium, and put Ar atmosphere protection after vacuuming. The ball milling process parameters are ball milling speed 200r / min, ball milling time 24h;

[0033] 3) The ball-milled powder was centrifuged at a speed of 4000r / min for 10min, the lower layer of slurry was removed, and vacuum-dried in a vacuum oven at 60°C for 2h to obtain a powder containing 0.3wt% ...

Embodiment 2

[0039] Add 1.5wt% Sn 42 Bi 58 Preparation of Bi by sintering aid 0.5 Sb 1.5 Te 3 Based thermoelectric composite thick film, comprising the following steps:

[0040] p-type Bi 0.5 Sb 1.5 Te 3 The ingot is broken, ground, and passed through a 120-mesh sieve to obtain a ready-to-use powder with a particle size of less than 120 μm;

[0041] Calculate and weigh the above Bi according to the mass percentage 0.5 Sb 1.5 Te 3 Powder 9.85g and sintering aid Sn 42 Bi 58 Add 0.15g of alloy powder into a high-energy ball mill tank with a ball-to-material ratio of 55:1, add 50ml of absolute ethanol as a ball mill medium, and put Ar atmosphere protection after vacuuming. The ball milling process parameters are ball milling speed 200r / min, ball milling time 24h;

[0042] The ball-milled powder was centrifuged at a speed of 4000r / min for 10min, the lower layer of slurry was removed, and vacuum-dried in a vacuum oven at 60°C for 2h to obtain a powder containing 1.5wt% Sn 42 Bi 58...

Embodiment 3

[0048] Preparation of Bi by adding 1wt% bismuth telluride nanowire sintering aid 0.5 Sb 1.5 Te 3 Based thermoelectric composite thick film, comprising the following steps:

[0049] 1) Preparation of Bi 2 Te 3 Nanowires

[0050] Weigh 0.1g SDS, 0.0183g Na 2 TeO 3 and 0.0150 g NaBH 4 , dissolved in 100mL water successively under magnetic stirring to form a homogeneous solution. Under the condition of ice-water bath, Na 2 TeO 3 and NaBH 4 The solution was added dropwise into the SDS solution and stirred continuously, the solution gradually turned black, and a dispersion of Te crystal seeds was obtained;

[0051] Mix 1g PVP K90 and 0.25g Na 2 TeO 3 Dissolve in 70mL of water, obtain a clear solution under magnetic stirring, transfer it with 10mL Te seed crystal dispersion and 1.5mL hydrazine hydrate solution into a stainless steel reaction kettle lined with polytetrafluoroethylene, and place it in a high-temperature furnace at 145°C to keep warm After 72 hours, the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| Seeback coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com