Cavitating jet cleaning disc with recovery function

A technology for cleaning disks and cavitation, applied in the field of cleaning, can solve the problems of unrealized garbage recovery, reduce cleaning speed, increase cleaning cost, etc., and achieve the effect of convenient underwater cleaning operation, fast and efficient recovery, and good recovery effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

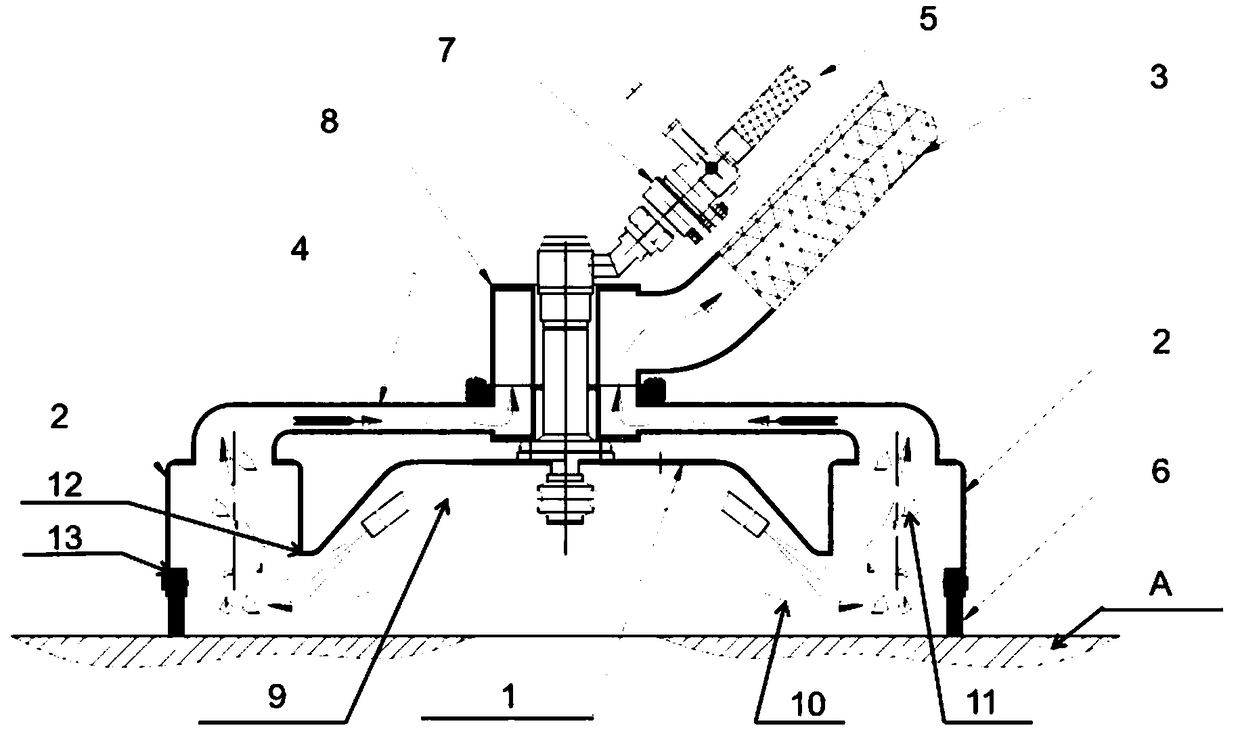

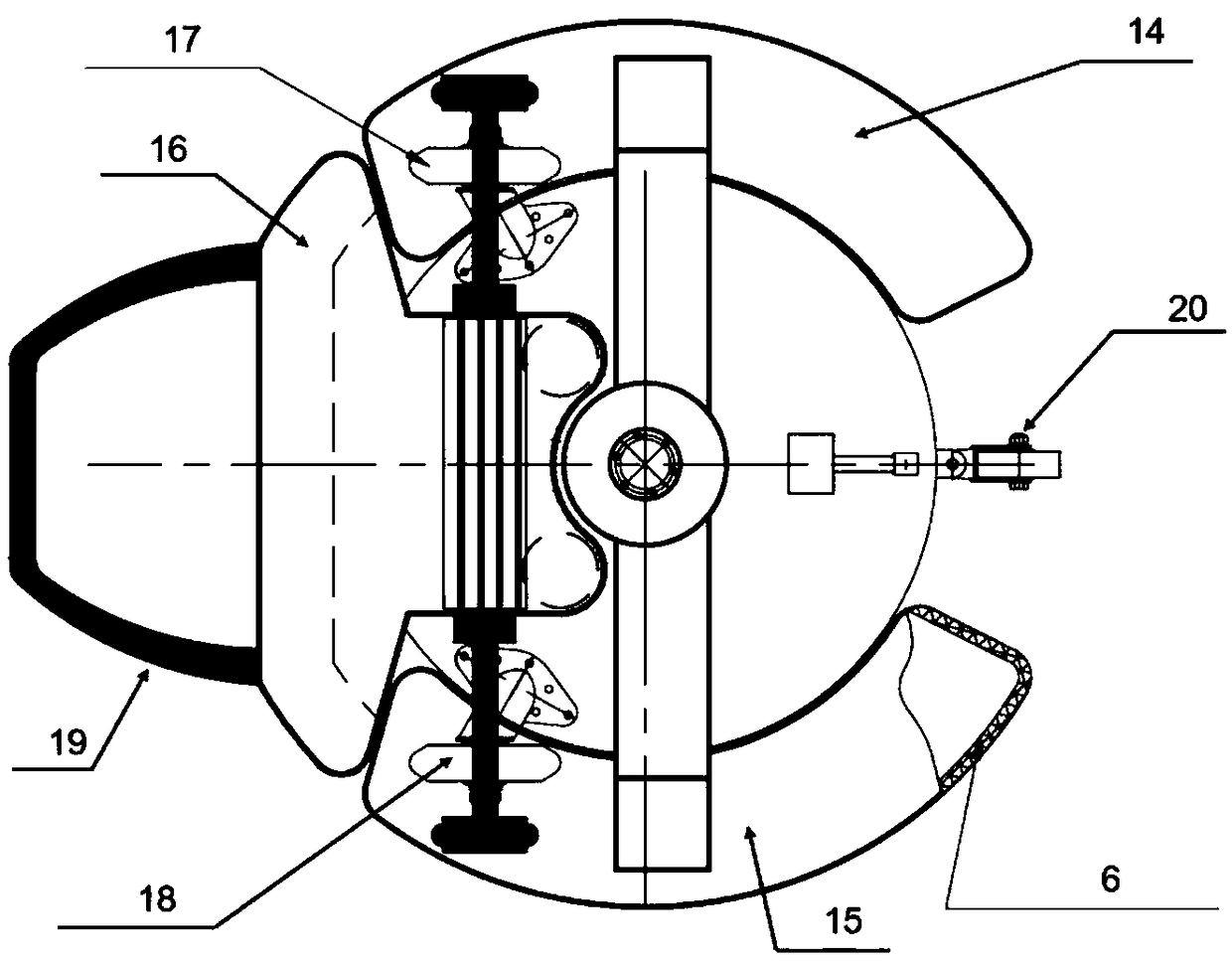

[0034] Such as figure 1 , 2 As shown, a cavitation jet cleaning tray with recovery function includes a cleaning tray 1, a suction cover 2, a sewage pipe 3, and a push handle frame 19;

[0035] The cleaning disc 1 includes a shell-shaped disc body, a hollow rotating shaft, a cleaning nozzle 9, a high-pressure liquid input pipe 5, and a propulsion nozzle; the top of the shell-shaped disc body is provided with a plurality of water inlets; the hollow rotating shaft is arranged on the top of the shell-shaped disc body Central position; the cleaning nozzle 9 is arranged inside the shell-shaped disc body and communicates with the hollow shaft, and the end of the cleaning nozzle 9 is provided with a turbine nozzle; the high-pressure liquid input pipe 5 and the propulsion nozzle are respectively connected with the hollow shaft It is connected and located above the shell-shaped disc body, and the high-pressure liquid input pipe 5 and the propulsion nozzle are provided with control valv...

Embodiment 2

[0054] The other parameters of this embodiment are the same as those of Embodiment 1, the difference being that the jetting direction of the water flow of the cleaning nozzle 9 is 30° to the horizontal direction and 40° to the vertical direction;

[0055] Therefore, when working underwater, the recovery efficiency of clams and other pollutants is good, and the cleaning efficiency is 100m 2 / 24h.

Embodiment 3

[0057] The other parameters of this embodiment are the same as those of Embodiment 1, the difference being that the jetting direction of the water flow of the cleaning nozzle 9 is 60° to the horizontal direction and 40° to the vertical direction;

[0058] Therefore, when working underwater, the recovery efficiency of clams and other pollutants is good, and the cleaning efficiency is 110m 2 / 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com