Coagulation precipitation equipment based on sludge concentration pool supernatant fluid backflow and method thereof

A sludge thickening tank, coagulation and sedimentation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The volume of the reaction tank and the sedimentation tank, the increase of the investment cost of water treatment, etc., can shorten the residence time, increase the cost of equipment construction, and reduce the cost of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

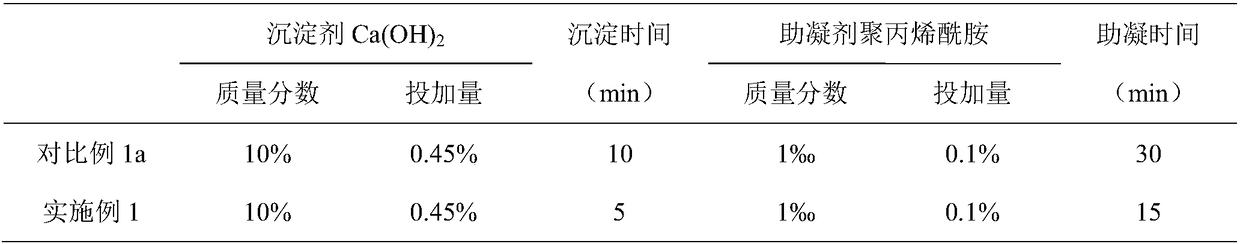

[0054] Treat the same industrial phosphorus-containing sewage as in Comparative Example 1, and the sewage treatment capacity is 300m 3 / d, the total phosphorus concentration is 10.2-50.5mg / L, and the water quality at the outlet of the sedimentation tank is controlled to meet the requirements of the national comprehensive sewage discharge standard GB 8978-1996.

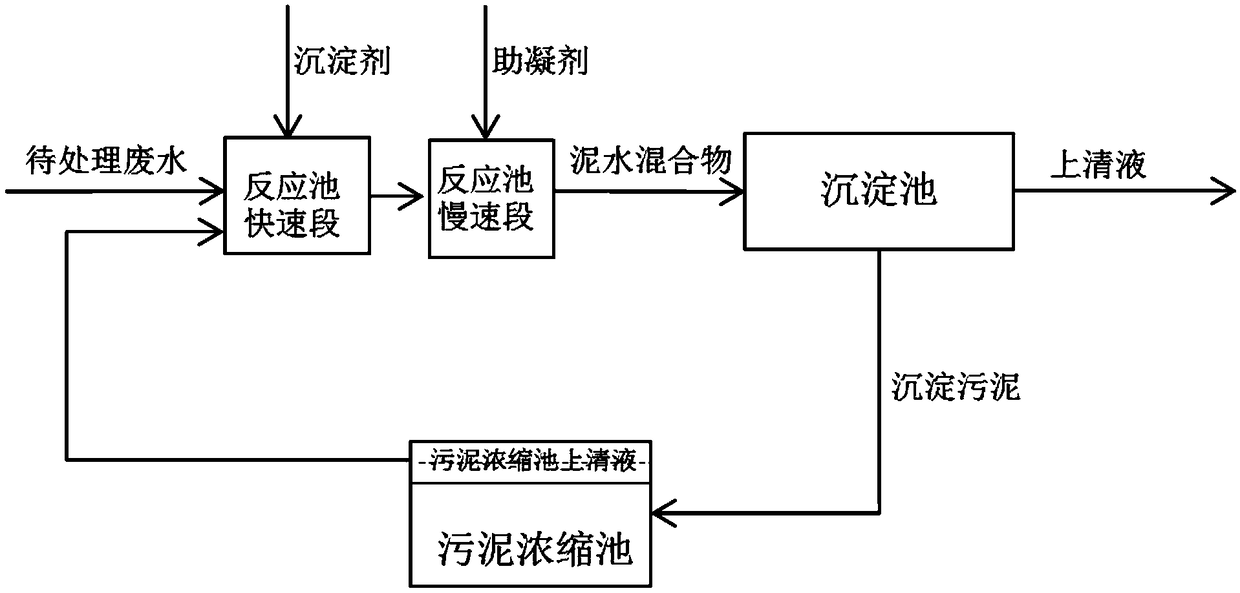

[0055] Such as figure 2 As shown, adopting a kind of coagulation sedimentation method based on the return flow of the supernatant of the sludge thickening tank of the present embodiment comprises the following steps:

[0056] (1) Make the sewage to be treated enter the fast section of the reaction tank, add a precipitant (mass percentage is 10% Ca(OH) 2 , the amount added is 0.45% of the sewage treatment capacity, that is, 1.35m 3 / d) rapid stirring (60rpm) for rapid precipitation (5min precipitation time) reaction;

[0057] (2) Step (1) After the precipitation reaction, the effluent flows into the slow section of ...

Embodiment 2

[0069] Treatment of copper-containing sewage, the sewage treatment capacity is 300m 3 / d, the total copper concentration is 100mg / L, and the effluent water quality at the outlet of the sedimentation tank is controlled to meet the secondary effluent requirements in the national comprehensive sewage discharge standard GB 8978-1996 with a total copper concentration of less than 1mg / L.

[0070] Such as figure 2 As shown, adopting a kind of coagulation sedimentation method based on the return flow of the supernatant of the sludge thickening tank of the present embodiment comprises the following steps:

[0071] (1) Make the sewage to be treated enter the fast section of the reaction tank, add a precipitant (1% polyaluminium chloride (PAC) by mass percentage), and the addition amount is 1% of the sewage treatment capacity (ie 3m 3 / d) rapid stirring (40rpm) for rapid precipitation (precipitation time 10min) reaction;

[0072] (2) Step (1) After the precipitation reaction, the effl...

Embodiment 3

[0080] Treatment of high COD organic wastewater, the sewage treatment capacity is 300m 3 / d, the COD concentration is 4000mg / L, and the COD of the effluent at the outlet of the sedimentation tank is controlled to meet the secondary effluent requirements in the national comprehensive sewage discharge standard GB 8978-1996, that is, less than 200mg / L.

[0081] Such as figure 2 As shown, adopting a kind of coagulation sedimentation method based on the return flow of the supernatant of the sludge thickening tank of the present embodiment comprises the following steps:

[0082] (1) Make the sewage to be treated enter the fast section of the reaction tank, add a precipitant (the mass percentage is 20% ferric chloride, and the addition is 0.08% of the sewage treatment capacity, i.e. 0.24m 3 / d) rapid stirring (30rpm) for rapid precipitation (precipitation time 8min) reaction;

[0083] (2) Step (1) After the precipitation reaction, the effluent flows into the slow section of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com