A preparation method of an antioxidant polypeptide of Chlorella vulgaris

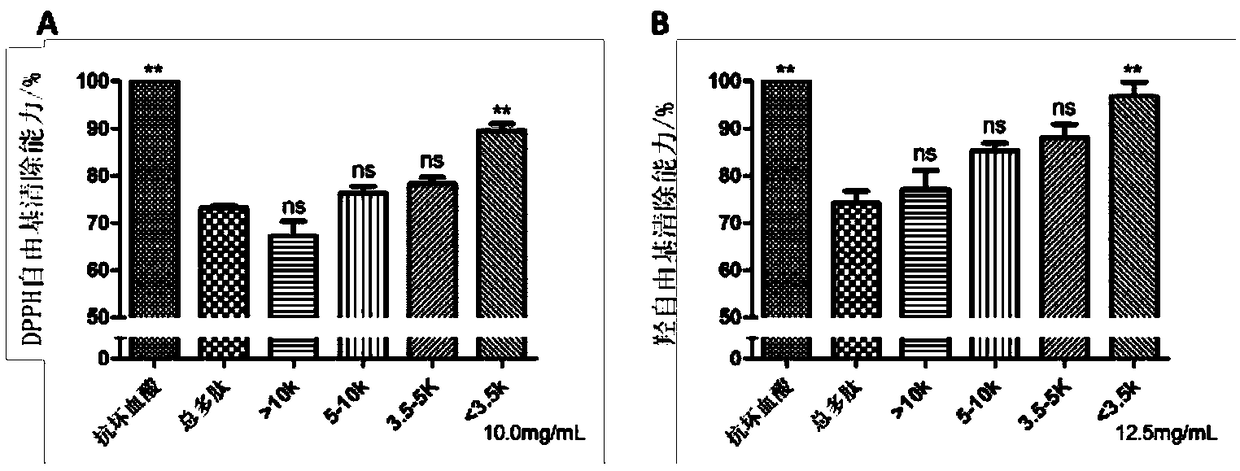

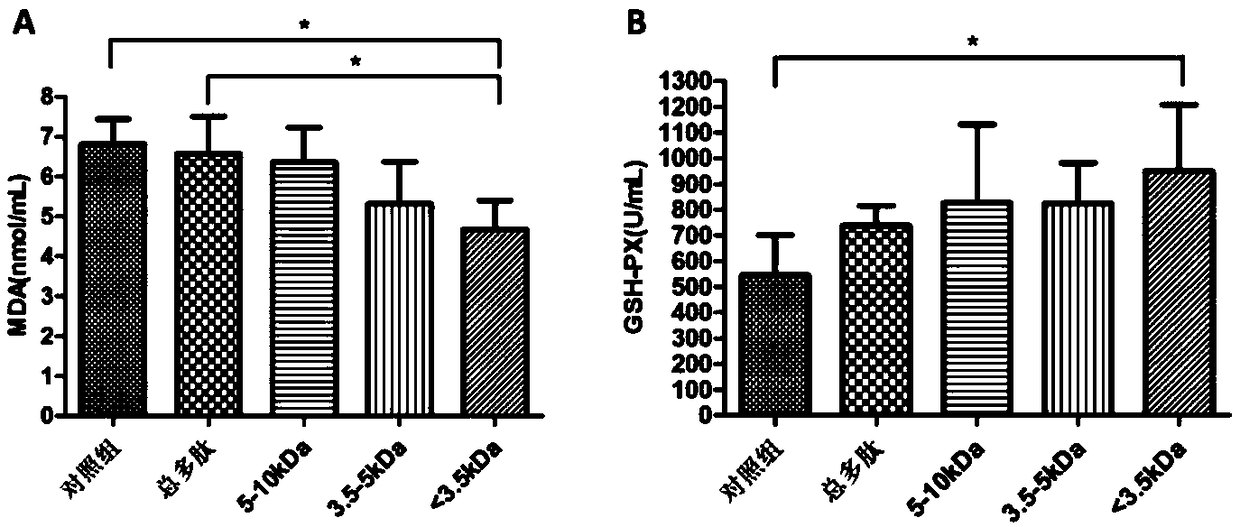

A technology of antioxidant peptides and chlorella, applied in the biological field, to achieve good in vitro scavenging of DPPH and hydroxyl radicals, good antioxidant activity, and improved extraction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of Chlorella cell wall enzymolysis solution and specific proteolysis solution

[0031] The cellulase, pectinase and various proteases used were purchased from Beijing Soleibao Technology Co., Ltd.

[0032] 1) The composition ratio of the chlorella cell wall enzymatic hydrolysis solution is:

[0033]

[0034] After the above-mentioned chlorella cell wall enzymatic hydrolysis solution is prepared, the pH is adjusted to 4.0 with 36% concentrated hydrochloric acid.

[0035] 2) The proportion of the specific proteolytic solution components is:

[0036]

[0037]

[0038] After preparing the above-mentioned specific proteolysis solution, adjust the pH to 9.5 with 1mol / L NaOH solution;

[0039] 2. Chlorella antioxidant polypeptide is prepared by the following steps:

[0040] 1) Weigh 500g of chlorella powder and add it to 4.5L 0.3mol / L NaOH dilute alkali solution, soak for 60min at 60°C to obtain pretreated chlorella liquid;

[0041] 2) The pretreated chlorella liquid obtaine...

Embodiment 2

[0064] 1. Preparation of Chlorella cell wall enzymolysis solution and specific proteolysis solution

[0065] The cellulase, pectinase and various proteases used were purchased from Beijing Soleibao Technology Co., Ltd.

[0066] 1) The weight ratio of the chlorella cell wall enzymatic hydrolysate is:

[0067]

[0068]

[0069] Adjust the pH to 4.0 with 36% concentrated hydrochloric acid;

[0070] 2) The weight ratio of the specific proteolysis solution is:

[0071]

[0072] Adjust the pH to 7.5~9.5 with 1mol / L NaOH solution;

[0073] 2. Prepared by the following steps:

[0074] 1) Weigh 750g of chlorella powder and add it to 4.25L 0.3mol / L NaOH dilute alkali solution, soak for 60min at 60°C to obtain pretreated chlorella liquid;

[0075] 2) The pretreated chlorella liquid obtained in step 1) was homogenized twice at a pressure of 55 MPa and centrifuged at 5000 rpm for 20 min. The supernatant A obtained was temporarily stored at 4°C, and the precipitate obtained Add to the chlorella cell wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com