Titanium diboride reinforced CuW alloy in-situ synthesis method

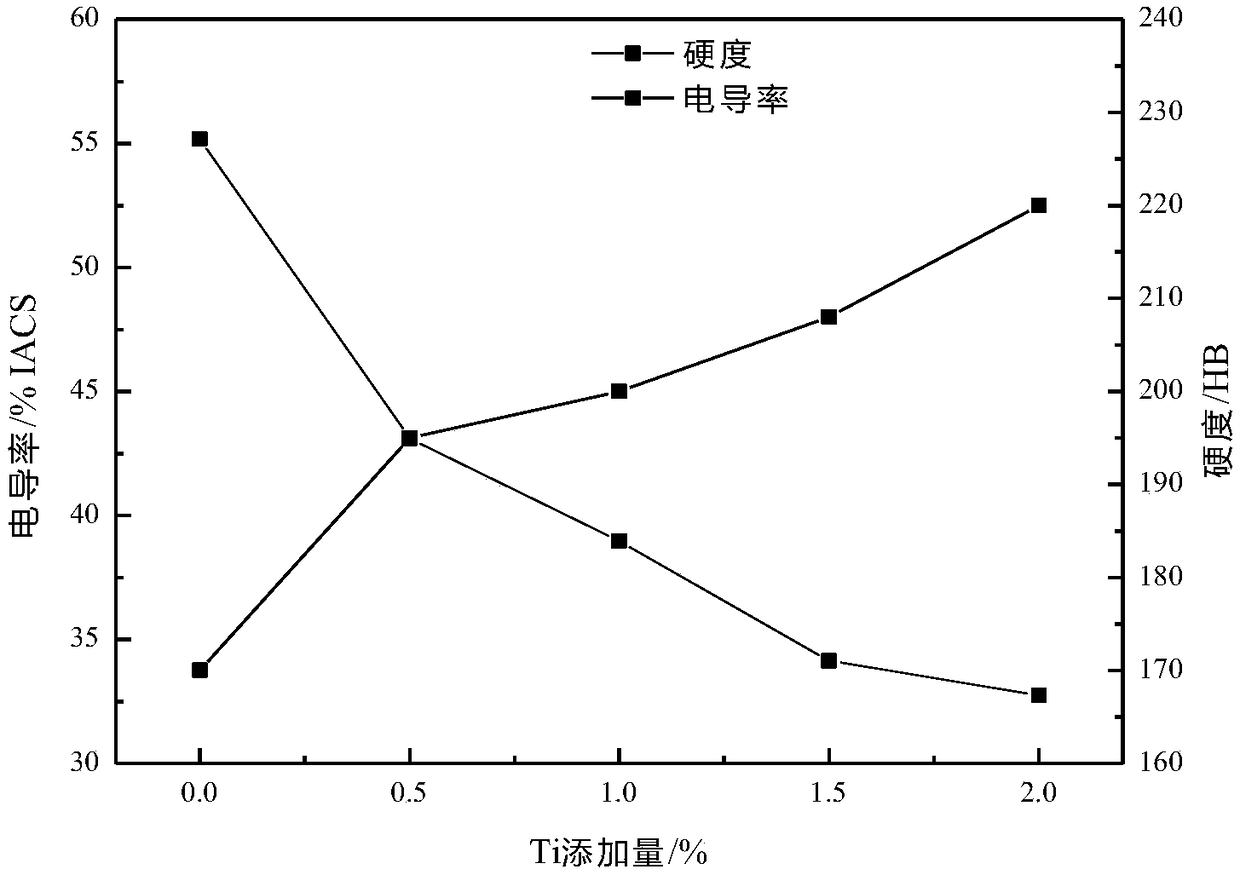

A titanium diboride, in-situ self-generation technology, applied in the direction of contacts, electrical components, circuits, etc., can solve problems such as copper liquid splashing, CuW electrical contact ablation, etc., to avoid surface pollution, facilitate the preparation process, reduce The effect of adding to the process of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

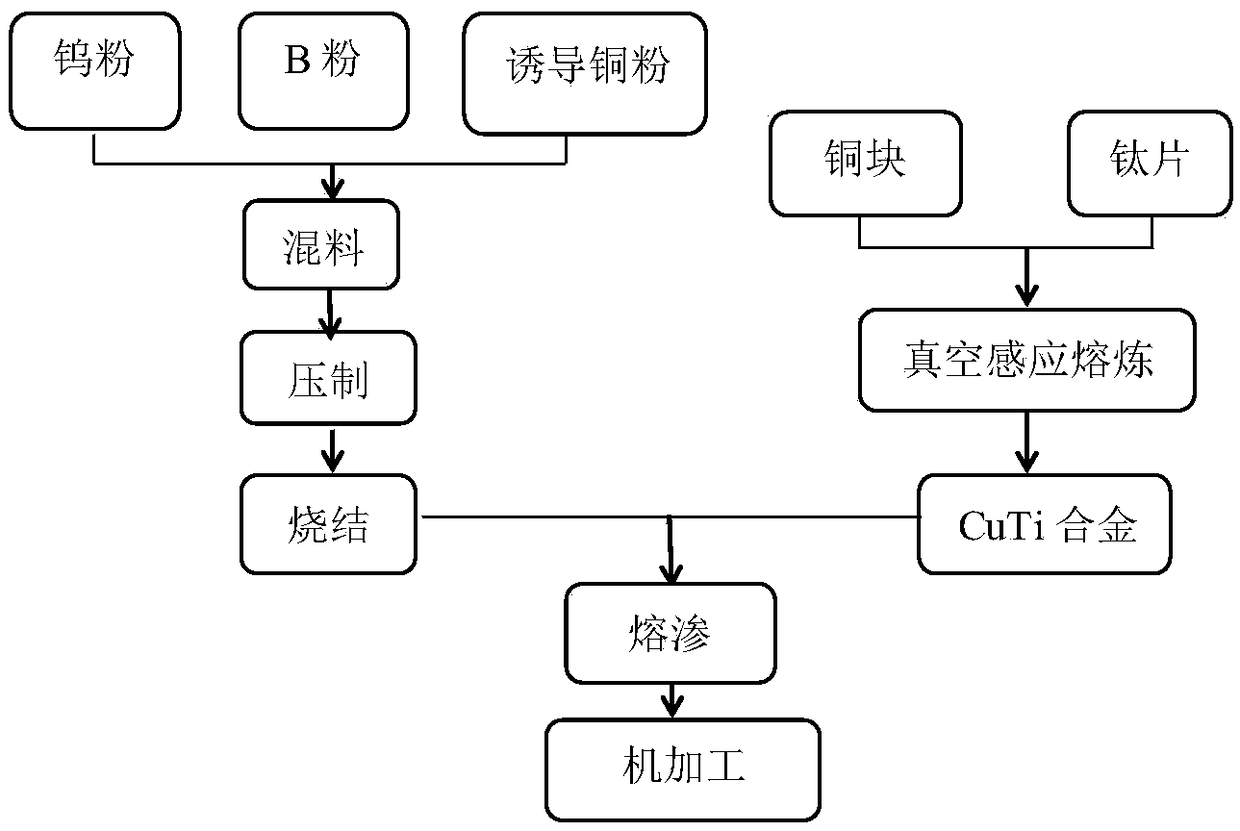

Method used

Image

Examples

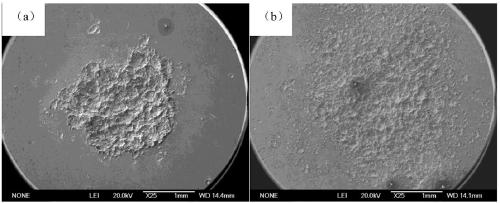

Embodiment 1

[0041] Put the polished Ti sheet (thickness 0.5mm) and Cu block into the vacuum induction melting furnace from bottom to top in turn, wherein the amount of Ti used is 0.5% of the mass of Cu used, and then vacuumed to 4×10 -3 Above Pa, fill a small amount of argon protective gas and start smelting. Firstly, the current is raised to 25A at 2A / min, the temperature is raised to 1000°C, and the temperature is kept for 4 minutes, and then the current is raised to 25A, the temperature is 1300°C, and the temperature is kept for 15 minutes, and the CuTi alloy is obtained by cooling with the furnace. Weigh W powder with an average particle diameter of 10 μm, and add B powder (average particle diameter at 100 nm) with a Ti molar ratio of 1:2, the amount of B powder added is 0.1% of the mass of W powder, and 5% of the mass of W powder. Copper powder (with an average particle size of 10 μm) was induced and mixed on a V-type mixer at 80 r / min for 4 hours. After mixing, a hydraulic press was...

Embodiment 2

[0043]Put the cleaned Ti sheet (thickness 1.2mm) and Cu block from bottom to top into the vacuum induction melting furnace in turn, wherein the amount of Ti used is 1.0% of the mass of Cu used, and then vacuumed to 4×10 -3 Above Pa, fill a small amount of argon protective gas and start smelting. First, the current is increased to 20A at 2A / min, the temperature is raised to 1100°C and kept for 5 minutes, and then the current is raised to 28A, the temperature is 1350°C, kept for 25 minutes, and cooled with the furnace to obtain a CuTi alloy. Weigh W powder with an average particle size of 15 μm, and add B powder (average particle size at 200nm) with a Ti molar ratio of 1:2, the amount of B powder added is 0.3% of the mass of W powder, and 8% of the mass of W powder Copper powder (with an average particle size of 20 μm) was induced and mixed on a V-type mixer at 50 r / min for 8 hours. After mixing, it was pressed and formed by a hydraulic press to obtain a W compact. The pressing...

Embodiment 3

[0045] Put the cleaned Ti sheet (thickness 1.5mm) and Cu block from bottom to top into the vacuum induction melting furnace in turn, wherein the amount of Ti used is 2.0% of the mass of Cu used, and then vacuumed to 4×10 -3 Above Pa, fill a small amount of argon protective gas and start smelting. Firstly, the current is raised to 24A at 2A / min, the temperature is raised to 1110°C and kept for 6 minutes, and then the current is raised to 26A, the temperature is 1400°C, kept for 28 minutes, and cooled with the furnace to obtain a CuTi alloy. Weigh W powder with an average particle size of 8 μm, and add B powder with a Ti molar ratio of 1:2 (average particle size is 300nm), the amount of B powder added is 0.5% of the mass of W powder, and 7% of the mass of W powder The induced copper powder (with an average particle size of 30 μm) was mixed on a 60r / min V-type mixer for 6 hours, and after mixing, it was pressed and formed by a hydraulic press to obtain a W compact. The pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com