Method for in-situ molten-salt electrodeposition of tungsten carbide/tungsten composite coating

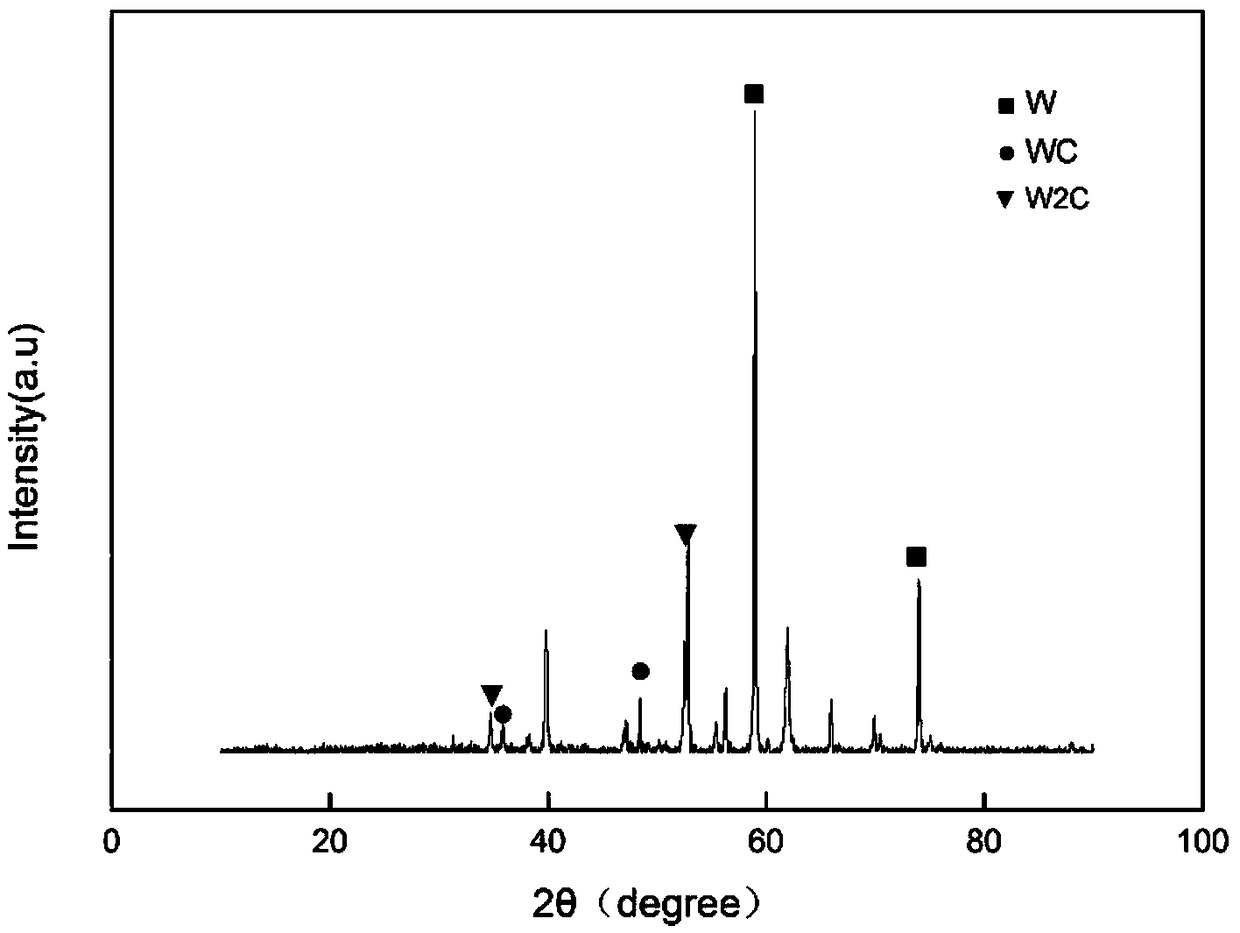

A composite coating and electrodeposition technology, used in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high oxygen content, no reports of tungsten carbide/tungsten composite coatings, weak crystallinity and matrix adhesion. , to achieve the effect of low cost, complete grain and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

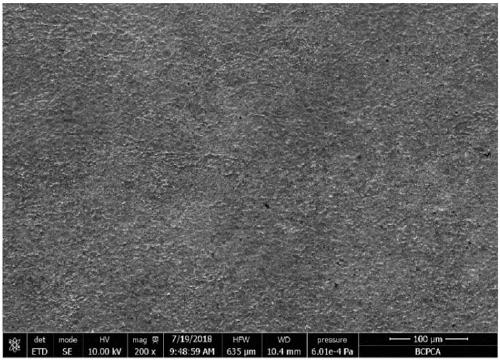

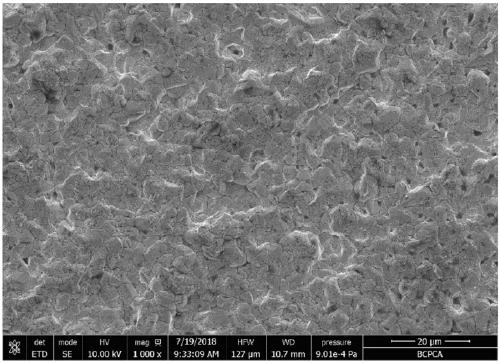

[0037] The embodiment of the present invention provides a method for in-situ electrodeposition of tungsten carbide / tungsten composite coating with molten salt, using waste tungsten carbide as auxiliary electrode, molybdenum plate as working electrode, and in-situ electrodeposition process by constant current step method preparation.

[0038] Specifically, include the following steps:

[0039] S1. Carry out simple mechanical cutting of waste tungsten carbide to obtain a suitable size, and mechanically polish it, soak it in lye for 20 minutes, then clean it with deionized water, ultrasonically clean it in acetone and alcohol, and dry it for later use;

[0040] S2, mechanically grinding and polishing the molybdenum plate until the surface is smooth, soaking in lye for 20 minutes, cleaning with deionized water, ultrasonic cleaning in acetone and alcohol, and drying for later use;

[0041] S3, the Na 2 WO 4 Pre-dried in a vacuum oven at 300°C for 12 hours, dehydrated, and weighe...

Embodiment 2

[0047] The embodiment of the present invention provides a method for in-situ electrodeposition of tungsten carbide / tungsten composite coating in molten salt, with the aid of waste WC-6Co cemented carbide (tungsten carbide-cobalt cemented carbide with a cobalt content of 6wt%) Electrode, with copper plate as working electrode and platinum wire as reference electrode, was prepared by constant potential step method in-situ electrodeposition process.

[0048] Specifically, include the following steps:

[0049] S1. Carry out simple mechanical cutting of waste WC-6Co cemented carbide to obtain a suitable size, and mechanically polish it, soak it in lye for 20 minutes, then clean it with deionized water, ultrasonically clean it in acetone and alcohol, and dry it spare;

[0050] S2. Mechanically grind and polish the copper plate until the surface is smooth, soak it in lye for 20 minutes, then clean it with deionized water, ultrasonically clean it in acetone and alcohol, and dry it fo...

Embodiment 3

[0054] The embodiment of the present invention provides a method for in-situ electrodeposition of tungsten carbide / tungsten composite coating with molten salt, using waste tungsten carbide as auxiliary electrode, stainless steel plate as working electrode, and in-situ electrodeposition process by constant current step method preparation.

[0055] Specifically, include the following steps:

[0056] S1. Carry out simple mechanical cutting of waste tungsten carbide to obtain a suitable size, and mechanically polish it, soak it in lye for 20 minutes, then clean it with deionized water, ultrasonically clean it in acetone and alcohol, and dry it for later use;

[0057] S2. The stainless steel plate is mechanically ground and polished until the surface is smooth, soaked in lye for 20 minutes, then cleaned with deionized water, ultrasonically cleaned in acetone and alcohol, and dried for later use;

[0058] S3, will K 2 WO 4 and KF are pre-dried in a vacuum oven at 300°C for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com