A kind of ultra-thin silicon nanosheet photocatalyst and its preparation method and application

A technology of silicon nanosheets and photocatalysts, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc. problem, to achieve the effect of low process cost, promotion of performance and application research, and large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment prepares ultra-thin silicon nanosheet photocatalyst according to the following steps:

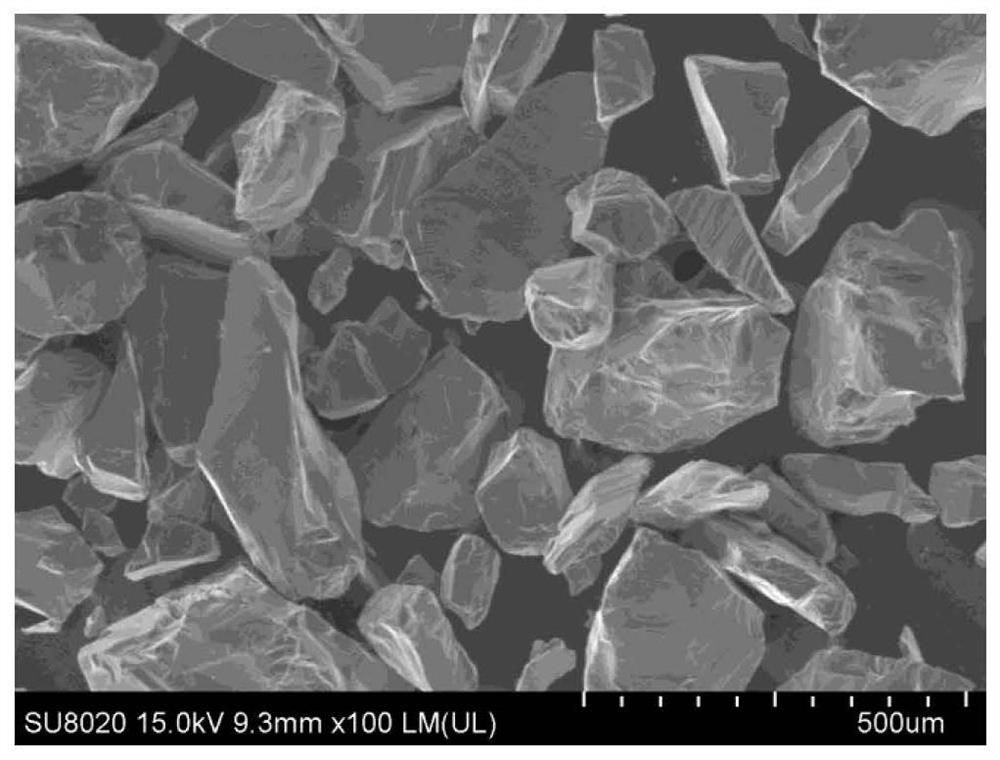

[0033] (1) Weigh 1g of commercial crystalline silicon powder and soak in liquid nitrogen for 12 hours;

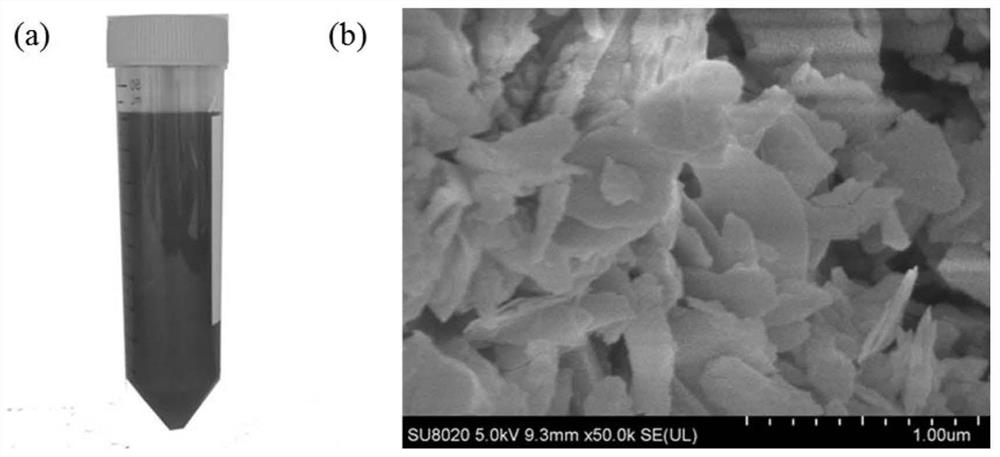

[0034] (2) Take out the soaked crystalline silicon powder, and after the liquid nitrogen is completely volatilized, then disperse the crystalline silicon powder into 200mL of isopropanol and water in a mixed solvent with a volume ratio of 1:1, and ultrasonically treat it at 120W for 8h. After ultrasonication, the sample was centrifuged at 1000rpm for 30min, and the supernatant was taken to obtain a suspension of ultra-thin silicon nanosheets;

[0035] (3) The ultrathin silicon nanosheet suspension was centrifuged at 10000 rpm for 30 min, and the precipitate was washed with deionized water and freeze-dried for 48 h to obtain the ultrathin silicon nanosheet photocatalyst.

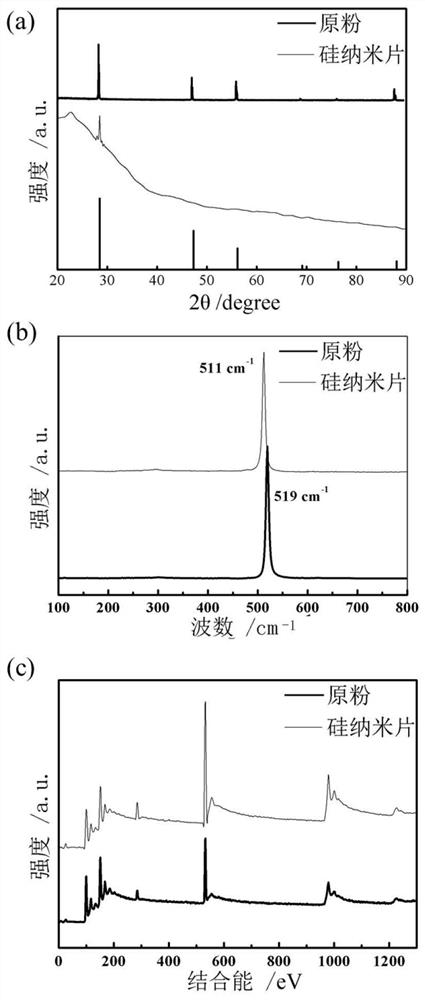

[0036] figure 2 (a), (b), and (c) are successively the XRD, Raman, and XPS characterization...

Embodiment 2

[0043] (1) Weigh 400 mg of commercial crystalline silicon powder and soak in liquid nitrogen for 24 hours;

[0044] (2) Take out the soaked crystalline silicon powder, and after the liquid nitrogen is completely volatilized, disperse the crystalline silicon powder into a mixed solvent composed of 100mL of isopropanol and water at a volume ratio of 1:1, and ultrasonically treat it at 100W for 4h. After ultrasonication, the sample was centrifuged at 2000rpm for 30min, and the supernatant was taken to obtain a suspension of ultra-thin silicon nanosheets;

[0045] (3) The ultrathin silicon nanosheet suspension was centrifuged at 10000 rpm for 30 min, and the precipitate was washed with deionized water and freeze-dried for 48 h to obtain the ultrathin silicon nanosheet photocatalyst.

[0046] After characterization, the ultra-thin silicon nanosheets obtained in this example have a thickness of 0.9-1.8nm and a diameter of 1.5-6.5μm; they were tested for their visible light photocata...

Embodiment 3

[0048] (1) Weigh 600 mg of commercial crystalline silicon powder and soak in liquid oxygen for 48 hours;

[0049] (2) Take out the soaked crystalline silicon powder, and after the liquid oxygen is completely volatilized, disperse the crystalline silicon powder into 200mL of isopropanol and water in a mixed solvent with a volume ratio of 1:1, and ultrasonically treat it for 6 hours at a power of 120W. After ultrasonication, the sample was centrifuged at 3000rpm for 30min, and the supernatant was taken to obtain a suspension of ultra-thin silicon nanosheets;

[0050] (3) The ultrathin silicon nanosheet suspension was centrifuged at 10000 rpm for 30 min, and the precipitate was washed with deionized water and freeze-dried for 48 h to obtain the ultrathin silicon nanosheet photocatalyst.

[0051] After characterization, the thickness of the ultra-thin silicon nanosheets obtained in this example is 0.6-1.5nm, and the size is 0.3-5.0μm; it is tested for the performance of visible li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com