High wear resistance slurry bed Fischer-Tropsch synthesis iron-based catalyst, preparation method and application

An iron-based catalyst, a Fischer-Tropsch synthesis technology, which is used in the preparation of liquid hydrocarbon mixtures, chemical instruments and methods, catalysts for physical/chemical processes, etc. Synthetic reactivity, easy for large-scale industrial production, and the effect of enhancing wear-resistant mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

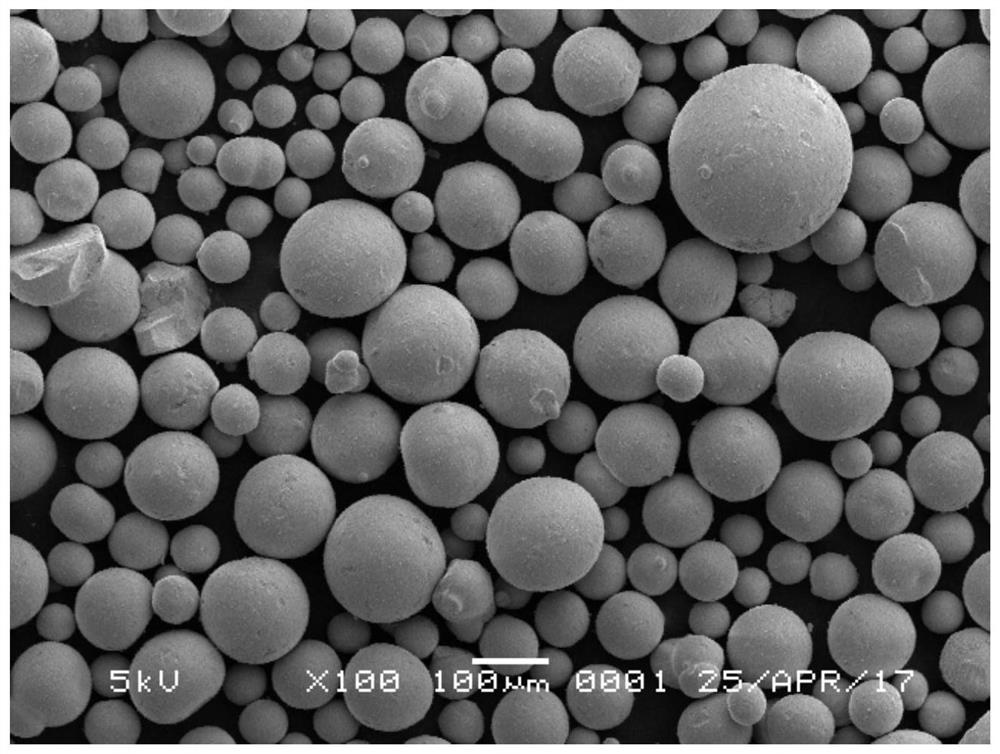

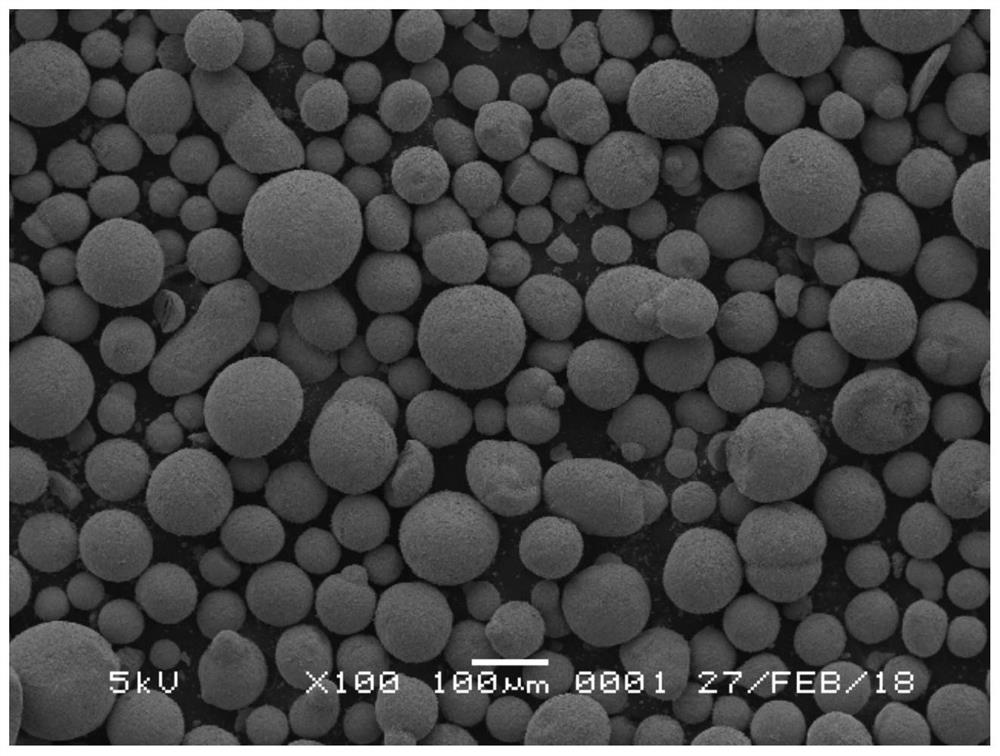

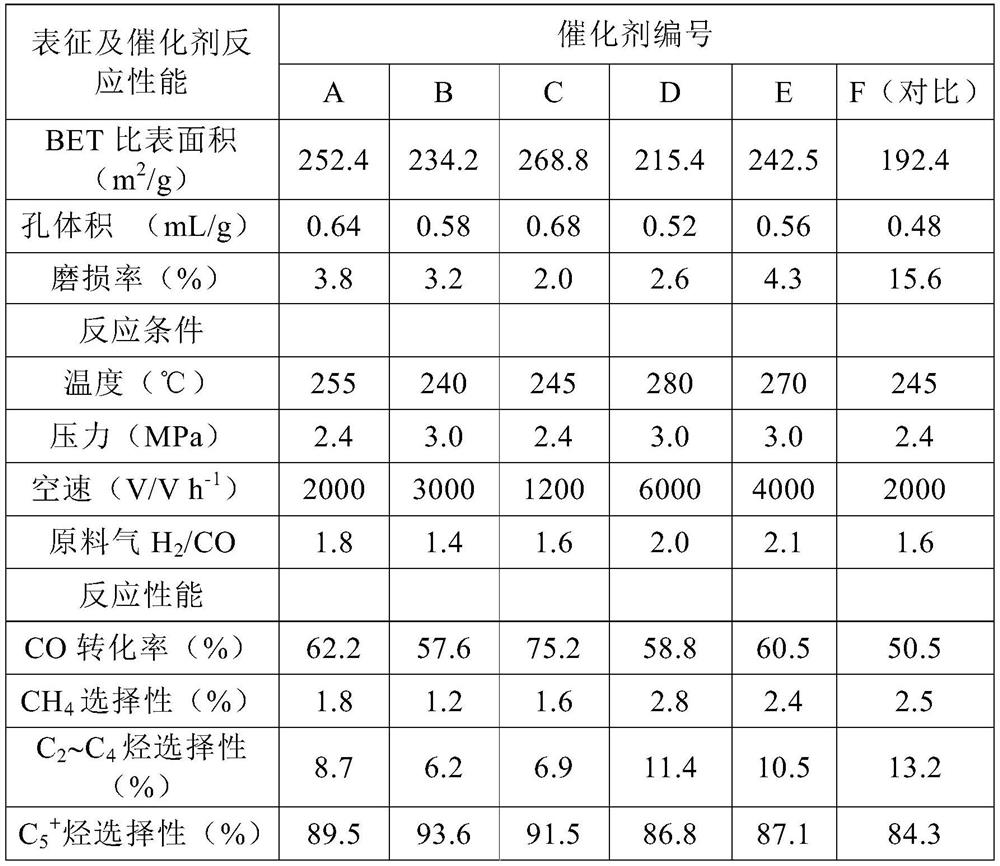

Embodiment 1

[0040] 10kg iron powder and 566g copper powder are dissolved in 90L56wt% nitric acid solution, dilute to obtain metal solution, wherein Fe content is 60g / L, and Cu content is 3.3g / L; 2 CO 3Add the aqueous solution into the reaction kettle and heat it to 65°C; at the same time, heat the above metal solution to 65°C and add it into the reaction kettle under rapid stirring to form a slurry. The reaction time is 30 minutes, and the pH value of the precipitated slurry is 7.5. Filter, Washing gave a co-precipitate with a solid content of 22.8%. Add 50kg of co-precipitate and deionized water to make a slurry again, the solid content of the slurry is about 15%, add 6.0kg of potassium silicate water glass solution (SiO 2 : 22.5wt%, K 2 O: 12.5wt%), mix well, use nitric acid to adjust the slurry pH to 7.15, keep at 85°C for 30 minutes, filter to obtain a filter cake with a solid content of 28.2%. Add the filter cake to 13.2 kg of 1.9 wt% AgNO 3 In the aqueous solution, the slurry is...

Embodiment 2

[0042] 10kg iron powder and 400g copper powder are dissolved in 85L60wt% nitric acid solution, dilute to obtain metal solution, wherein Fe content is 40g / L, Cu content is 1.6g / L; 10.5wt%Na 2 CO 3 Add the aqueous solution into the reaction kettle and heat it to 85°C; at the same time, heat the above metal solution to 85°C and add it into the reaction kettle under rapid stirring to form a precipitation slurry. The reaction time is 15 minutes, and the pH value of the precipitation slurry is 6.0. Filter , washing to obtain a co-precipitate with a solid content of 26%. 40kg coprecipitate, add deionized water to form a slurry, the slurry solid content is about 20%, add 3.0kg potassium silicate water glass solution (SiO 2 : 26.5wt%, K 2 O: 13.5wt%), mix evenly, use nitric acid to adjust the slurry pH to 6.9, keep it at 65°C for 45 minutes, then add 3.0kg of 15wt% AgNO 3 (0.5kg nanometer tungsten carbide is dispersed in it in advance), add 2.7kg of 30wt% alkaline silica gel, keep t...

Embodiment 3

[0044] 15kg iron powder and 900g copper powder are dissolved in 110L45wt% nitric acid solution, dilute to obtain metal solution, wherein Fe content is 50g / L, Cu content is 3.0g / L; 9.5wt%Na 2 CO 3 Add the aqueous solution into the reaction kettle and heat it to 50°C; at the same time, heat the above metal solution to 50°C and add it into the reaction kettle under rapid stirring to form a precipitation slurry. The precipitation reaction time is 60 minutes, and the pH value of the slurry is 8.0. Filter 1. Washing to obtain a precipitate co-precipitate with a solid content of 24.5%. 80kg of precipitated co-precipitate is added deionized water to make a slurry again, and the solid content of the slurry is about 14%, and 6.5kg of potassium silicate water glass solution (SiO 2 : 27.0wt%, K 2 O: 13.0wt%), mix evenly, use nitric acid to adjust the pH value of the slurry to 7.4, keep it at 50°C for 20 minutes, and filter to obtain a filter cake with a solid content of 30.1%. Add the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com