Method for performing multi-stage cyclic utilization on methanol to olefin catalyst synthetic wastewater

A technology of methanol to olefins and catalysts, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc. It can solve the problem of waste water reuse ratio and has not proposed a multi-stage recycling method with high controllability and auxiliary templating agent solubility. , cost, high toxicity requirements, difficult to control the proportion of raw materials, etc., to achieve high utilization rate, excellent and stable performance, and reduce the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

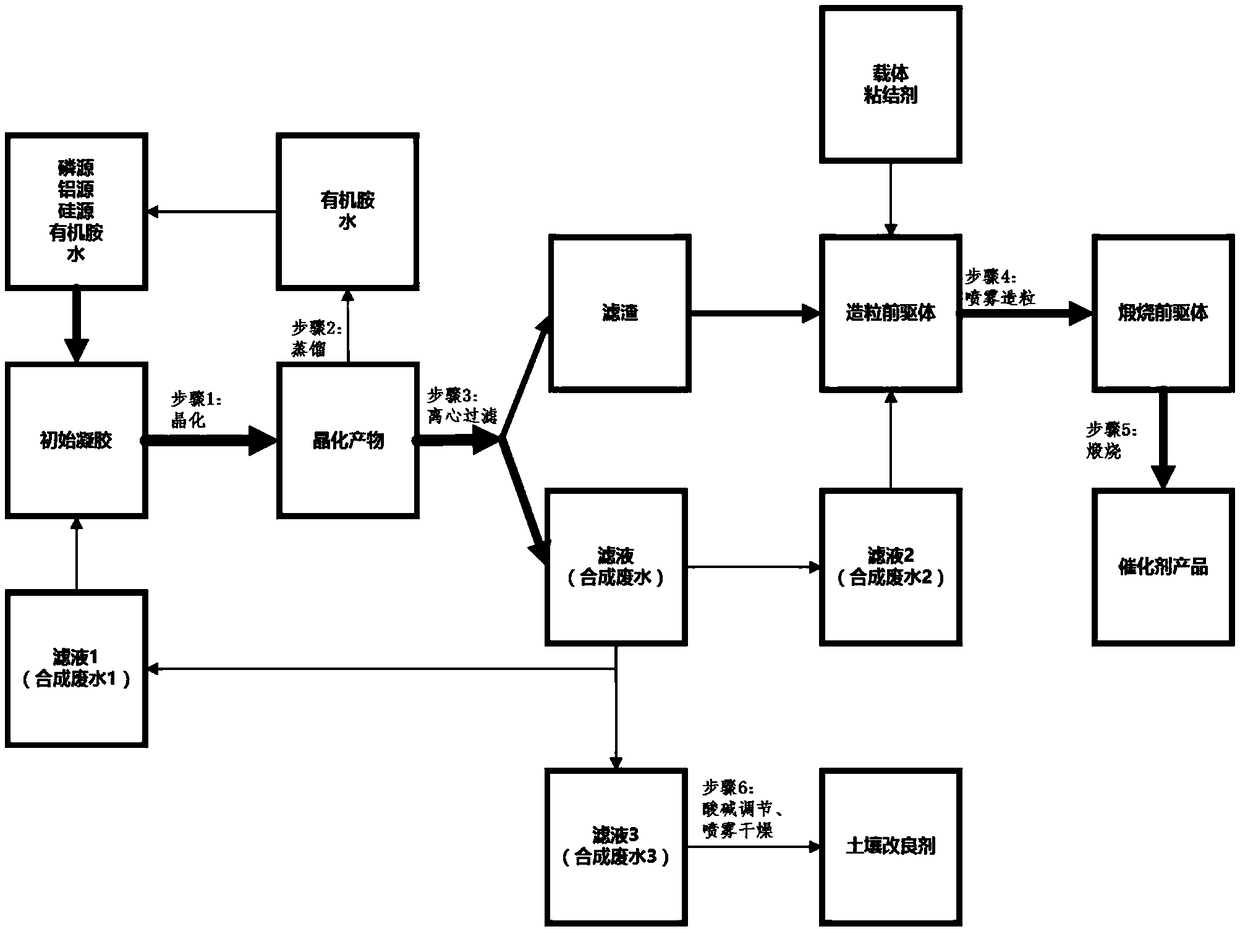

[0022] like figure 1 As shown, in this embodiment, a method for multi-stage recycling of methanol-to-olefins catalyst synthesis wastewater, the methanol-to-olefins catalyst synthesis wastewater is divided into three parts: the first part uses the microcrystalline molecular sieve product in the wastewater as a crystal seed, and simultaneously utilizes its Phosphorus sources, silicon sources, aluminum sources, water and organic amines are used for crystallization to synthesize molecular sieves; the second part uses the active ingredients of microcrystalline molecular sieve products in wastewater and the adhesive properties of amorphous gels to spray catalysts Granulation; the remaining third part is to use the rich nitrogen and phosphorus elements, pH buffering properties and molecular sieve adsorption properties in the wastewater to produce soil conditioners.

[0023] Specifically include the following steps:

[0024] Step 1: Partially synthesized waste water, phosphoric acid,...

Embodiment 2

[0032] like figure 1As shown, in this embodiment, a method for multi-stage recycling of methanol-to-olefins catalyst synthesis wastewater, the methanol-to-olefins catalyst synthesis wastewater is divided into three parts: the first part uses the microcrystalline molecular sieve product in the wastewater as a crystal seed, and simultaneously utilizes its Phosphorus sources, silicon sources, aluminum sources, water and organic amines are used for crystallization to synthesize molecular sieves; the second part uses the active ingredients of microcrystalline molecular sieve products in wastewater and the adhesive properties of amorphous gels to spray catalysts Granulation; the remaining third part is to use the rich nitrogen and phosphorus elements, pH buffering properties and molecular sieve adsorption properties in the wastewater to produce soil conditioners.

[0033] Include the following steps:

[0034] Step 1: The initial gel is prepared from the partial synthesis wastewater...

Embodiment 3

[0042] like figure 1 As shown, in this embodiment, a method for multi-stage recycling of methanol-to-olefins catalyst synthesis wastewater, the methanol-to-olefins catalyst synthesis wastewater is divided into three parts: the first part uses the microcrystalline molecular sieve product in the wastewater as a crystal seed, and simultaneously utilizes its Phosphorus sources, silicon sources, aluminum sources, water and organic amines are used for crystallization to synthesize molecular sieves; the second part uses the active ingredients of microcrystalline molecular sieve products in wastewater and the adhesive properties of amorphous gels to spray catalysts Granulation; the remaining third part is to use the rich nitrogen and phosphorus elements, pH buffering properties and molecular sieve adsorption properties in the wastewater to produce soil conditioners.

[0043] Include the following steps:

[0044] Step 1: Prepare the initial gel with the partial synthesis wastewater of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap