Foamed element and preparation method thereof

A foamed cement and ordinary Portland cement technology, applied in the field of cement, can solve the problem of low strength, etc., and achieve the effects of improving structural compactness, increasing strength and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

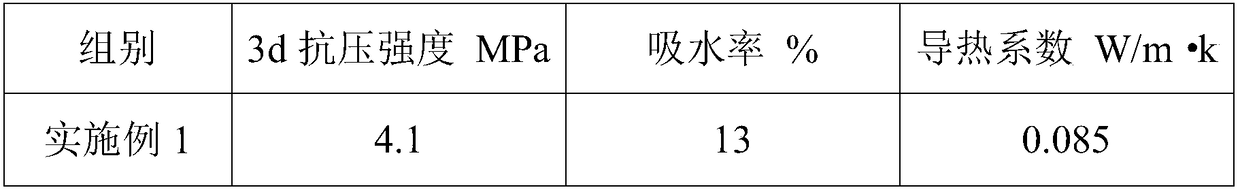

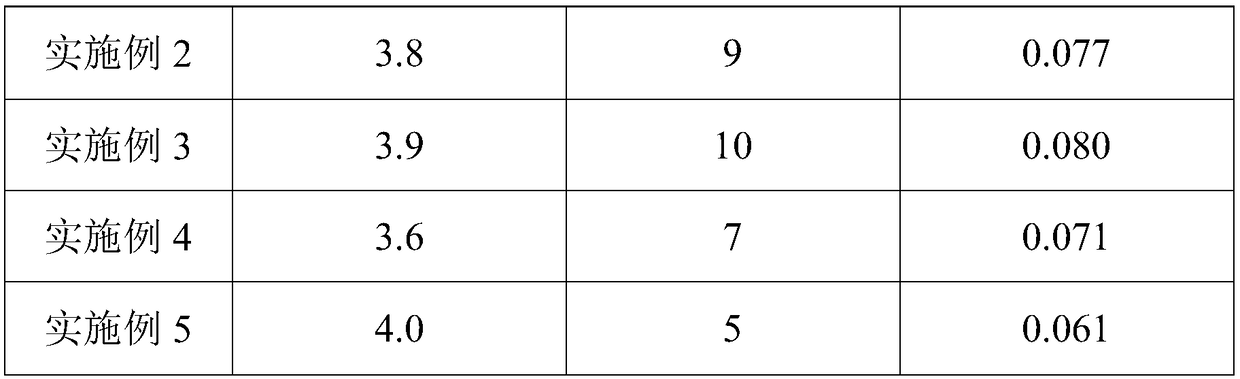

Examples

Embodiment 1

[0017] A kind of foam cement, its raw material comprises by weight: 65 parts of ordinary Portland cement, 12.5 parts of fly ash, 2.5 parts of sodium dodecylsulfonate, 0.75 parts of tea saponin, 0.6 parts of foam stabilizer, waterproof 1.25 parts of water reducing agent, 0.075 parts of water reducing agent, 2 parts of reinforcing agent, 35 parts of water, wherein the reinforcing agent is polypropylene fiber, basalt fiber and carbon fiber.

[0018] The preparation method of the above-mentioned foamed cement comprises the following steps: mixing and foaming sodium dodecylsulfonate, tea saponin and water to obtain a foam solution; mixing ordinary Portland cement, fly ash, foam stabilizer, waterproof Mixing agent, water reducing agent and reinforcing agent, adding foam solution and mixing, injection molding, curing to obtain foamed cement, wherein the temperature of water is 42°C.

Embodiment 2

[0020] A kind of foam cement, its raw material comprises by weight: 60 parts of ordinary Portland cement, 15 parts of fly ash, 2 parts of sodium dodecylsulfonate, 1 part of tea saponin, 0.5 part of foam stabilizer, waterproof 1.5 parts of agent, 0.05 part of disodium methylene bis-naphthalene sulfonate, 3 parts of reinforcing agent, 32 parts of water, wherein, reinforcing agent is polypropylene fiber, basalt fiber and carbon fiber, wherein, polypropylene fiber, basalt fiber and carbon fiber The weight ratio is 4:0.5:0.8;

[0021] The length of polypropylene fiber, basalt fiber and carbon fiber is 4mm.

[0022] The preparation method of the above-mentioned foamed cement comprises the following steps: mixing and foaming sodium dodecylsulfonate, tea saponin and water to obtain a foam solution; mixing ordinary Portland cement, fly ash, foam stabilizer, waterproof Mixing agent, water reducing agent and reinforcing agent, adding foam solution and mixing, injection molding, curing t...

Embodiment 3

[0024] A kind of foam cement, its raw material comprises by weight: 70 parts of ordinary Portland cement, 10 parts of fly ash, 3 parts of sodium dodecylsulfonate, 0.5 part of tea saponin, 0.7 part of foam stabilizer, waterproof 1 part of agent, 0.1 part of disodium methylene bis-naphthalene sulfonate, 1 part of reinforcing agent, 39 parts of water, wherein, reinforcing agent is polypropylene fiber, basalt fiber and carbon fiber, wherein, polypropylene fiber, basalt fiber and carbon fiber The weight ratio is 2:1:0.6;

[0025] The length of polypropylene fiber, basalt fiber and carbon fiber is 5mm;

[0026] The specific surface area of fly ash is 800m 2 / kg;

[0027] The foam stabilizer is lauroyl diethanolamine and gum arabic, wherein the weight ratio of lauroyl diethanolamine and gum arabic is 1:1;

[0028] The waterproofing agent is sodium methyl siliconate and water glass, wherein the weight ratio of sodium methyl siliconate and water glass is 2:1.

[0029] The prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com