Safety and environment-friendly firework composite material and preparation method thereof

A composite material, safety and environmental protection technology, applied in the direction of explosives composite components, offensive equipment, explosives processing equipment, etc., can solve the problems that affect the fireworks display effect, hidden dangers in production safety, a large amount of black smoke, etc., achieve drug stability, improve safety, The effect of good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

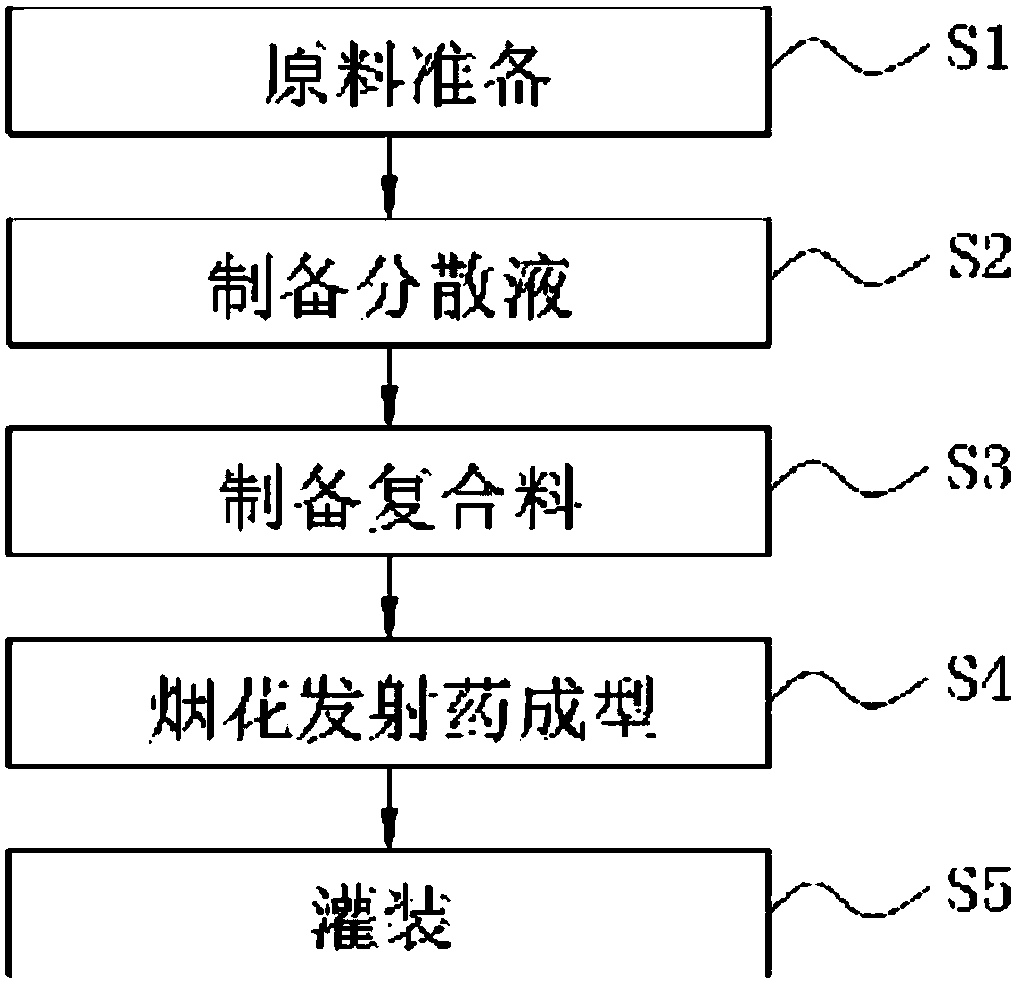

[0019] Example 1: See figure 1 , the invention provides a kind of safe and environment-friendly fireworks composite material, comprising the following raw materials in parts by weight: 30 parts of modified cellulose nitrate, 15 parts of terephthalic acid, 5 parts of perlite powder, 3 parts of modified carbon powder, potassium perchlorate 3 parts, 8 parts of aluminum hydroxide, 8 parts of antistatic acrylic resin, 6 parts of potassium hydroxide, 2 parts of potassium hydrogen phthalate, 3 parts of stabilizer, 2 parts of single base powder, 9 parts of strong agent powder and 10 parts of water .

[0020] According to the above technical scheme, the formula of modified nitrocellulose includes nitrocellulose and additives, the additives include light stabilizers, flame retardants, antistatic agents, colorants and dispersants, and the light stabilizers are 2,4-dihydroxydi Benzophenone, flame retardant is aluminum hydroxide, antistatic agent is sodium alkylsulfonate, colorant is isoi...

Embodiment 2

[0030] Example 2: See figure 1 , the invention provides a kind of safe and environment-friendly fireworks composite material, comprising the following raw materials in parts by weight: 35 parts of modified cellulose nitrate, 20 parts of terephthalic acid, 8 parts of perlite powder, 5 parts of modified carbon powder, potassium perchlorate 9 parts, 10 parts of aluminum hydroxide, 10 parts of antistatic acrylic resin, 10 parts of potassium hydroxide, 4 parts of potassium hydrogen phthalate, 5 parts of stabilizer, 4 parts of single base powder, 10 parts of strong agent powder and 15 parts of water .

[0031]According to the above technical scheme, the formula of modified nitrocellulose includes nitrocellulose and additives, the additives include light stabilizers, flame retardants, antistatic agents, colorants and dispersants, and the light stabilizers are 2,4-dihydroxydi Benzophenone, flame retardant is aluminum hydroxide, antistatic agent is sodium alkylsulfonate, colorant is i...

experiment example

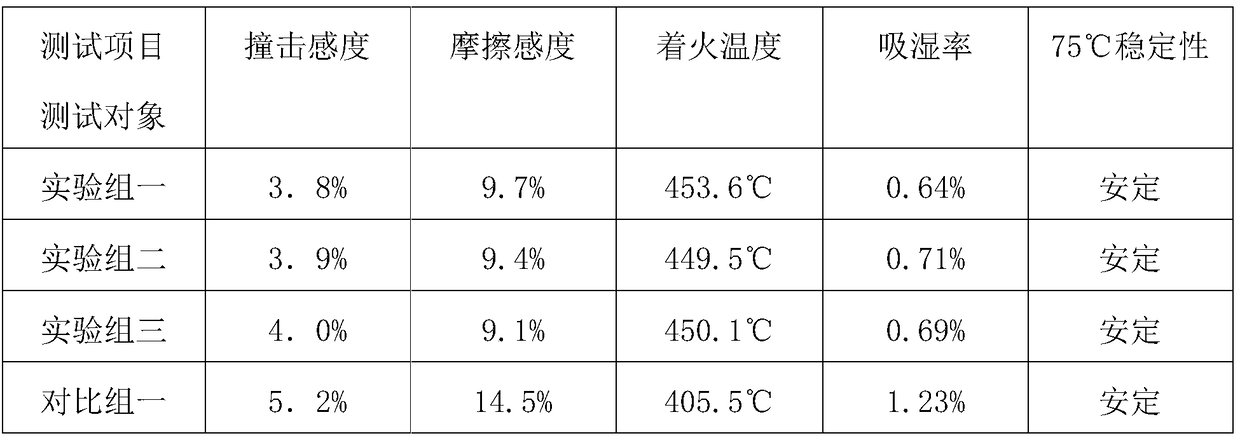

[0042] Experimental object: the fireworks propellant prepared in the embodiment of the present invention was used as the experimental group 1, the experimental group 2 and the experimental group 3, and the fireworks propellant on the market was selected as the comparison group 1, and the comparison group 1 used NY757-2003 fireworks propellant .

[0043] Experimental purpose: To test the impact sensitivity, friction sensitivity, ignition temperature, moisture absorption rate and 75°C stability of each group of fireworks propellants.

[0044] Experimental method: According to the national firework propellant testing standard and the national standard SN / T0306.4-2006, the fireworks propellant prepared in this experimental group and the fireworks propellant in the comparison group 1 were used to impact each group of fireworks propellant with professional equipment. Sensitivity, friction sensitivity, ignition temperature, moisture absorption rate and 75°C stability test, and record...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com