Method for preparing temperature-responsive comb-structure polycarboxylic acid through terminal group functionalization

A temperature-responsive, comb-like structure technology, applied in the field of temperature-responsive polycarboxylic acid materials, can solve the problems of limiting industrial application potential and not considering the application of temperature response behavior, so as to reduce the dependence on preparation methods, inhibit shrinkage cracking, reduce The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

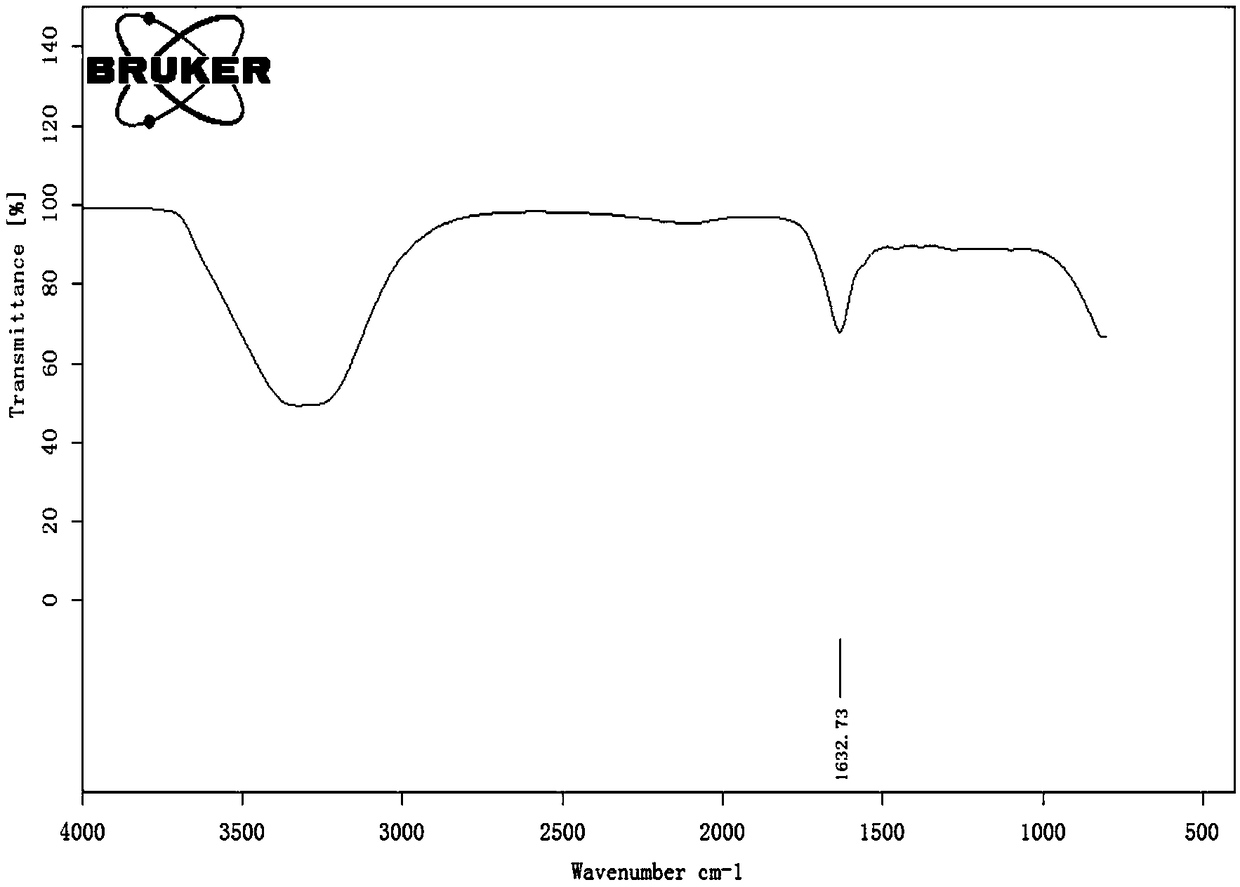

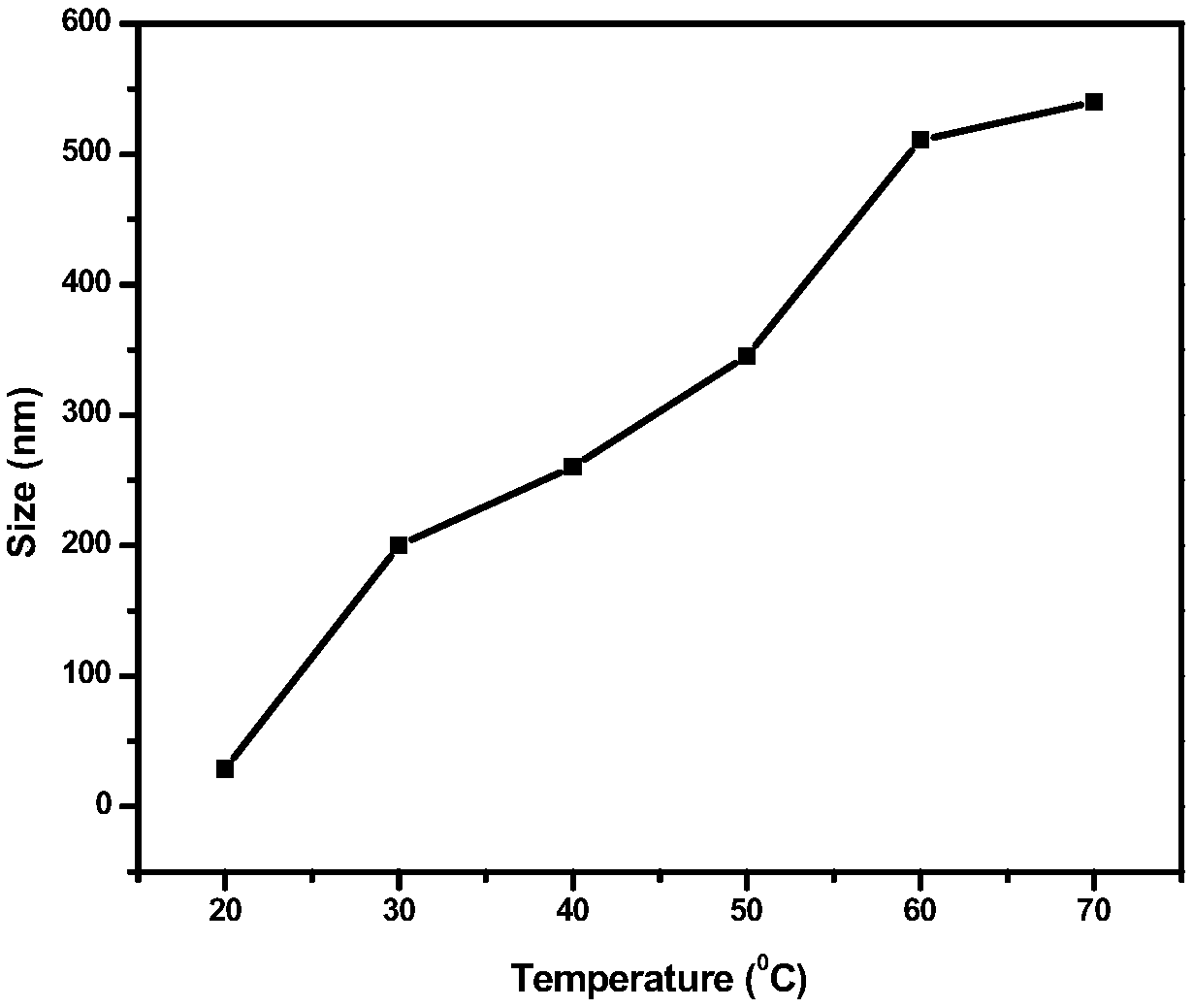

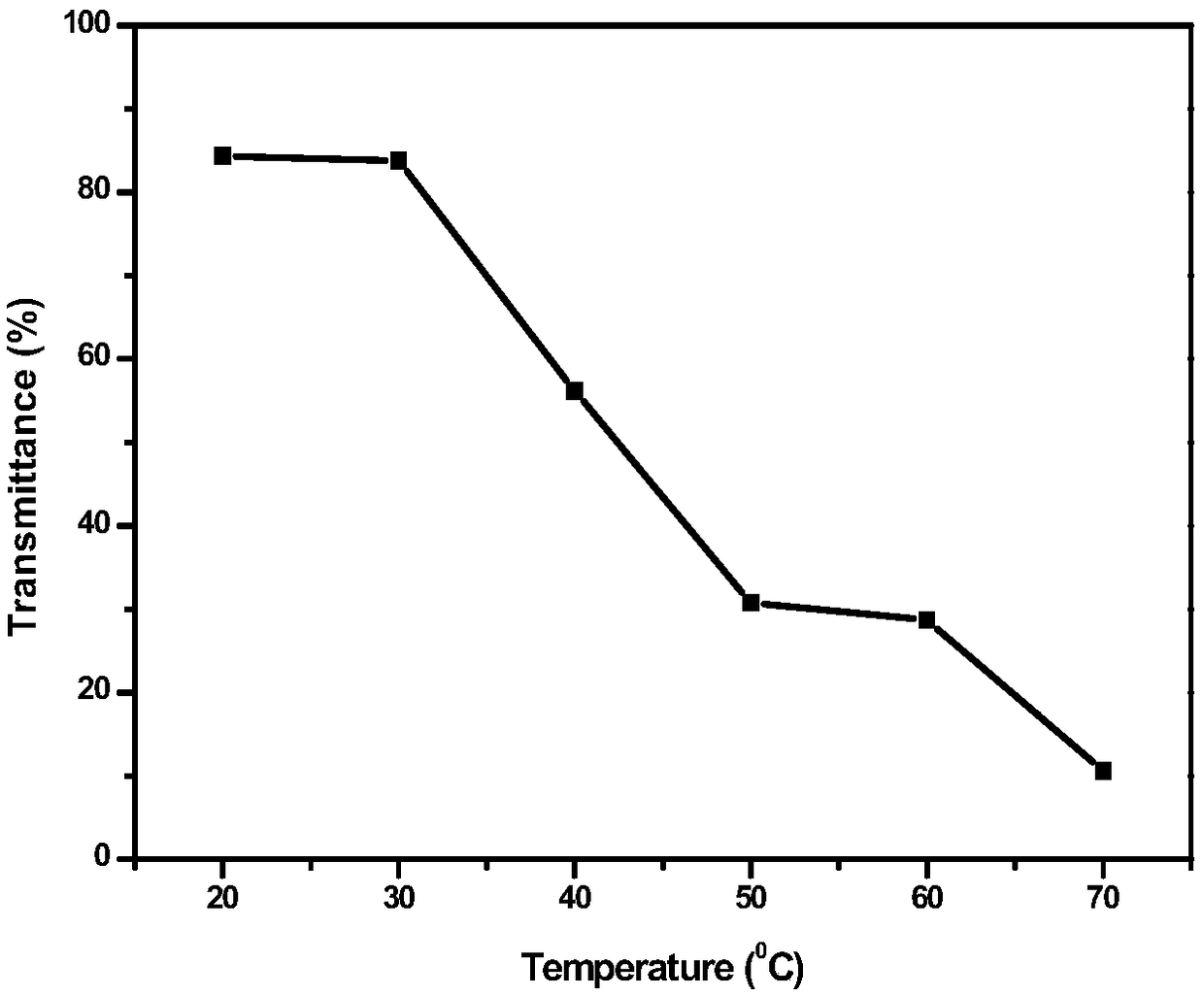

[0034] First, 72.81g of N,N-dimethylformamide was added to the reactor, the temperature was raised to 70°C, 7.11g of azobisisoheptanonitrile was added and stirred for 25 minutes until it was evenly mixed, and then 24.27g of N-isopropyl Mixed solution of methacrylamide and 1.49g 2-mercaptoethanol for 10 hours, after the dropwise addition, continue to react at a constant temperature of 70°C for 5 hours to obtain a self-polymerized product poly-N-isopropylmethacrylamide solution; 9.68g allyl Add bromine, 10.34g N,N-diisopropylethylamine and 0.19g benzyltrimethylammonium chloride to the self-polymerization product solution in sequence, stir and adjust the temperature to 50°C, react at a constant temperature of 50°C for 12 hours and then depressurize N,N-dimethylformamide and excess reagents were removed by distillation to obtain unsaturated poly-N-isopropylmethacrylamide macromonomer; 27.37g of unsaturated poly-N-isopropylmethacrylamide Dissolve acrylamide macromonomer in 16.42g o...

Embodiment 2

[0036] First, add 91.60g of aniline into the reactor, raise the temperature to 90°C, add 5.10g of dibenzoyl peroxide and stir for 20 minutes until it is evenly mixed, then add dropwise 18.32g of N-propylacrylamide and 2.98g of 3-mercapto Mixed solution of propanol for 8 hours, after the dropwise addition, continue to react at a constant temperature of 90°C for 4 hours to obtain a self-polymerized product poly-N-propylacrylamide solution; mix 8.15g 3-chloro-2-methylpropene, 13.95g tetramethyl Add ethylenediamine and 0.27g benzyltriethylammonium chloride to the self-polymerization product solution in turn, stir and adjust the temperature to 70°C, react at a constant temperature of 70°C for 9 hours, and then distill off aniline and excess reagents under reduced pressure to obtain Unsaturated poly-N-propylacrylamide macromonomer; dissolve 23.05g of unsaturated poly-N-propylacrylamide macromonomer in 18.44g of solvent water, heat up to 70°C, stir for 20 minutes and wait It is mixed...

Embodiment 3

[0038] First, 280.56g of tetrahydrofuran was added to the reactor, the temperature was raised to 120°C, 1.72g of di-tert-butyl peroxide was added and stirred for 10 minutes until it was evenly mixed, then 23.38g of N,N-dimethylacrylamide and 11.06g2 -The mixed solution of mercaptoethanol for 1 hour, after the dropwise addition, continue to react at a constant temperature of 120°C for 1 hour to obtain a self-polymerized product poly N,N-dimethylacrylamide solution; 10.71g of allyl chloride, 217.14g of N,N- Diisopropylethylamine and 0.72g tetraethylammonium iodide were added to the self-polymerization product solution in sequence, stirred and adjusted to 120°C, reacted at a constant temperature of 120°C for 2 hours, and then distilled off tetrahydrofuran and excess reagents under reduced pressure to obtain Unsaturated poly N,N-dimethylacrylamide macromonomer; dissolve 29.05g of unsaturated poly N,N-dimethylacrylamide macromonomer in 34.86g of solvent water, heat up to 90°C, Stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com