An electrolyte and an electrochemical device

An electrolyte and electrochemical technology, applied in the field of energy storage materials, can solve the problems of cycle performance and storage performance to be improved, achieve excellent high temperature and high pressure cycle performance and storage performance, reduce reduction and decomposition, and reduce the effect of battery gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0139] (1) Preparation of the compound of general formula I-1:

[0140] Its reaction equation is:

[0141]

[0142] The specific preparation process is:

[0143] 1. Add the P-2 aqueous solution with a concentration of 30-40% to the raw material P-1 dropwise within 20-60 minutes and stir rapidly. After the dropwise addition, stir rapidly for 15-30 hours, and stir in an oil bath at 70-90°C for 3-5 hours under reflux. A colorless fuming viscous liquid intermediate product I-1-1 was obtained;

[0144] 2. Continue to join K 2 CO 3 , KI, anhydrous acetonitrile; stir quickly to form a solid-liquid mixed phase, quickly add raw material P-3 at 40-60°C, continue stirring for 10-20h, then cool to room temperature, separate and purify to obtain the compound shown in formula I-1.

[0145] (two) preparation of general formula I-2 compound:

[0146] Its reaction equation is:

[0147]

[0148] The specific preparation process is:

[0149] Anhydrous sodium carbonate, raw material ...

Synthetic example 1

[0156]

[0157] 1. Add 37% formaldehyde aqueous solution dropwise to 1,3-propylenediamine within 0.5h and stir rapidly. After the dropwise addition, stir rapidly for 20h, then reflux and stir in an oil bath at 80°C for 4h to obtain a colorless fuming viscous liquid intermediate product Hexahydropyrimidine;

[0158] 2. Continue to join K 2 CO 3 , KI, anhydrous acetonitrile; stir quickly to form a solid-liquid mixed phase, add β-chloropropionitrile within 0.5h at 60°C, continue stirring for 17h, cool to room temperature, separate and purify to obtain the compound of formula A2.

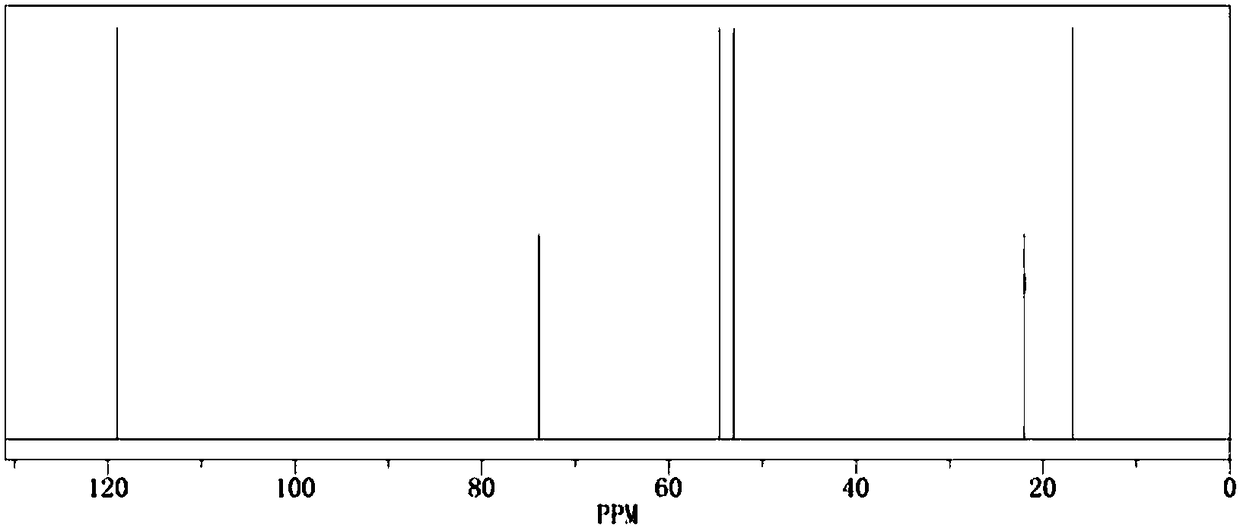

[0159] Carbon NMR spectrum such as figure 1 shown.

Synthetic example 2

[0161]

[0162] Anhydrous sodium carbonate, piperazine and β-chloropropionitrile were mixed in absolute ethanol, and the reaction was stirred for 4h. The crude product was obtained by washing with hot ethanol several times, and recrystallized to obtain the compound of formula A8.

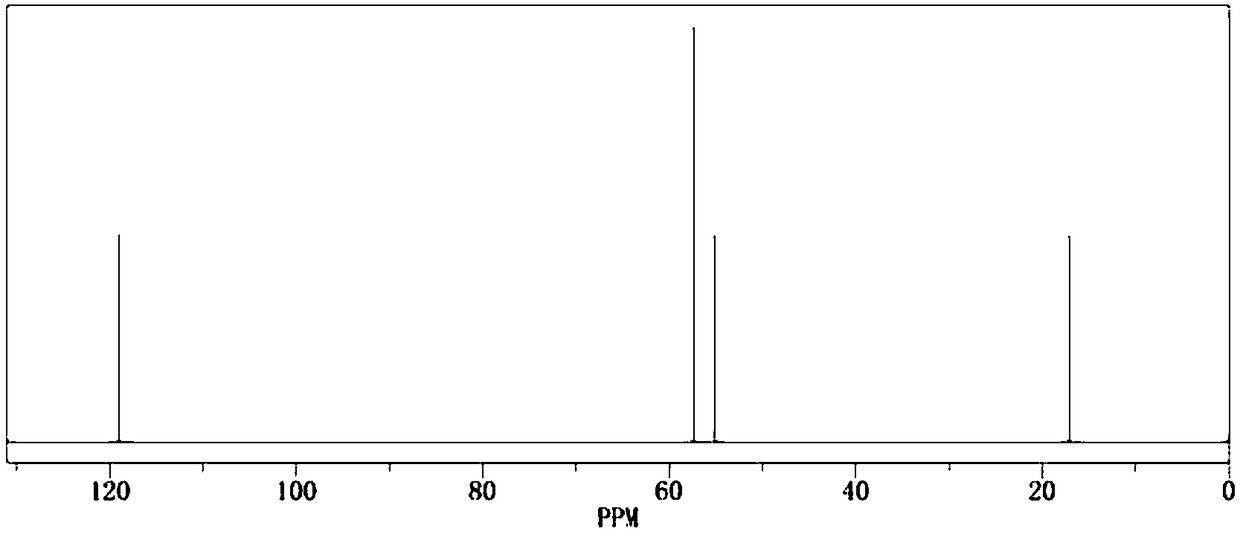

[0163] Carbon NMR spectrum such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com