Preparation method of bisphenol A polyoxyethylene ether with narrow molecular weight distribution

A narrow molecular weight distribution, polyoxyethylene ether technology, applied in the direction of ether preparation, alkylene oxide preparation ether, ester reaction preparation ether, etc., to achieve the effect of less by-products, easy to obtain raw materials, and improve product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

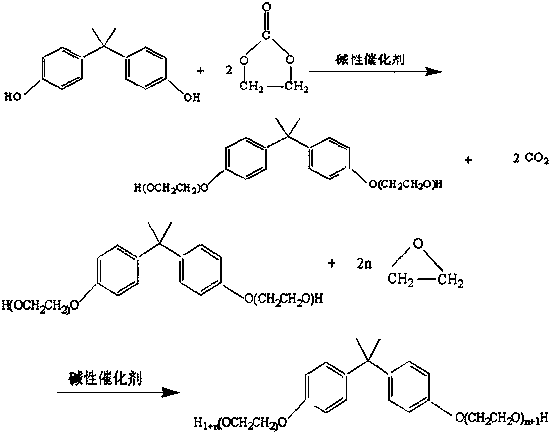

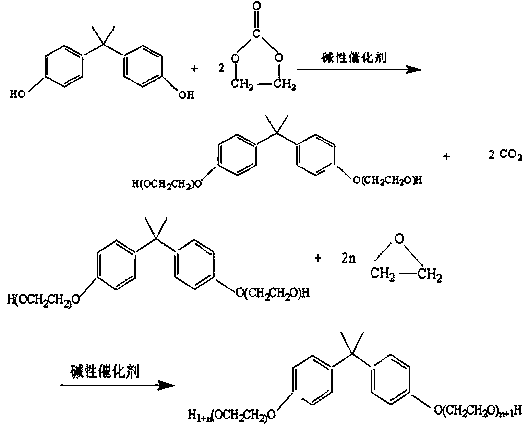

Method used

Image

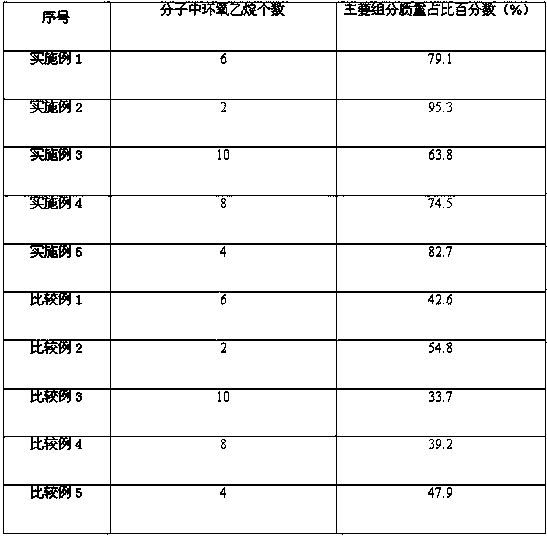

Examples

Embodiment 1

[0019] Example 1 Preparation of bisphenol A polyoxyethylene (6) ether

[0020] Add 1.0mol (228.0g) bisphenol A, 2.0mol

[0021] (176.0g) ethylene carbonate and 2.83g potassium methoxide, open the pressure relief valve, the pressure relief valve is connected to the lye absorption tank through a pipeline, slowly raise the temperature to 40°C, and react for 2 hours; then, close the pressure relief valve, and the epoxy Connect the ethane metering tank to the pressure kettle, and replace the gas in the kettle with nitrogen for 3 times. After the temperature of the kettle rises to 120°C, 4.0mol (176.0g) of ethylene oxide is fed in for 1.5 hours, and the reaction is continued for 0.5 hours. After completion, cool down, release the pressure, add acetic acid to neutralize, put

[0022] Bisphenol A polyoxyethylene (6) ether.

Embodiment 2

[0023] Example 2 Preparation of bisphenol A polyoxyethylene (2) ether

[0024] Add 1.5mol (342.0g) bisphenol A, 3.0mol

[0025] (264.0g) ethylene carbonate and 2.42g sodium hydroxide, open the pressure relief valve, the pressure relief valve is connected to the lye absorption tank through a pipeline, slowly raise the temperature to 50°C, and react for 1.0 hour. However

[0026] Finally, close the pressure relief valve, connect the ethylene oxide metering tank to the pressure kettle, replace the gas in the kettle with nitrogen for 3 times, wait until the temperature of the kettle rises to 100°C, and feed 0mol (0g) of ethylene oxide for 0 hours. Finished, continue to react for 0 hours. After the reaction is completed, cool down, release the pressure, add acetic acid for neutralization, and discharge to obtain bisphenol A polyoxyethylene (2) ether.

Embodiment 3

[0027] Example 3 Preparation of bisphenol A polyoxyethylene (10) ether

[0028] Add 0.5mol (114.0g) bisphenol A, 1.0mol

[0029] (88.0g) ethylene carbonate and 2.02g potassium hydroxide, open the pressure relief valve, the pressure relief valve is connected to the lye absorption tank through a pipeline, slowly raise the temperature to 30°C, and react for 3.0 hours. Then, close the pressure relief valve, connect the ethylene oxide metering tank to the autoclave, replace the gas in the autoclave with nitrogen for 3 times, wait until the temperature of the autoclave rises to 140°C, and feed 4.0mol (176.0g) of ethylene oxide, 3.5 After one hour passed, the reaction was continued for 0.5 hour. After the reaction is completed, cool down, release the pressure, add acetic acid for neutralization, and discharge to obtain bisphenol A polyoxyethylene (10) ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com