Lignin type benzoxazine and preparation method thereof

A technology of benzoxazine and lignin, which is applied in the field of benzoxazine preparation, can solve the problems of low addition amount and poor solubility, and achieve the effects of increased addition amount, increased thermal stability, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of phenolated lignin

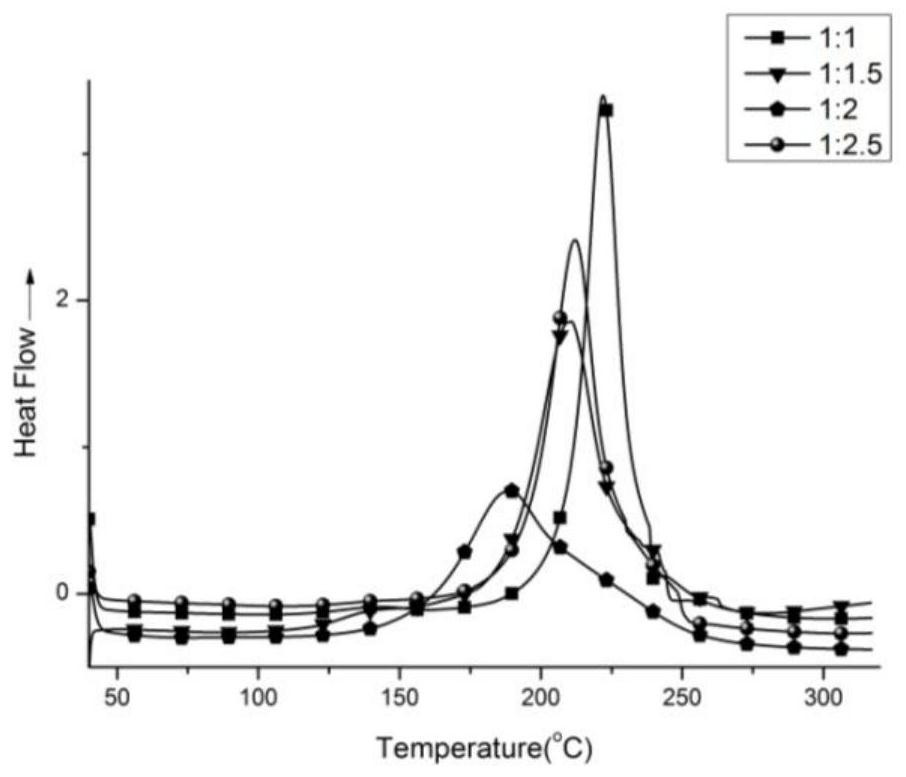

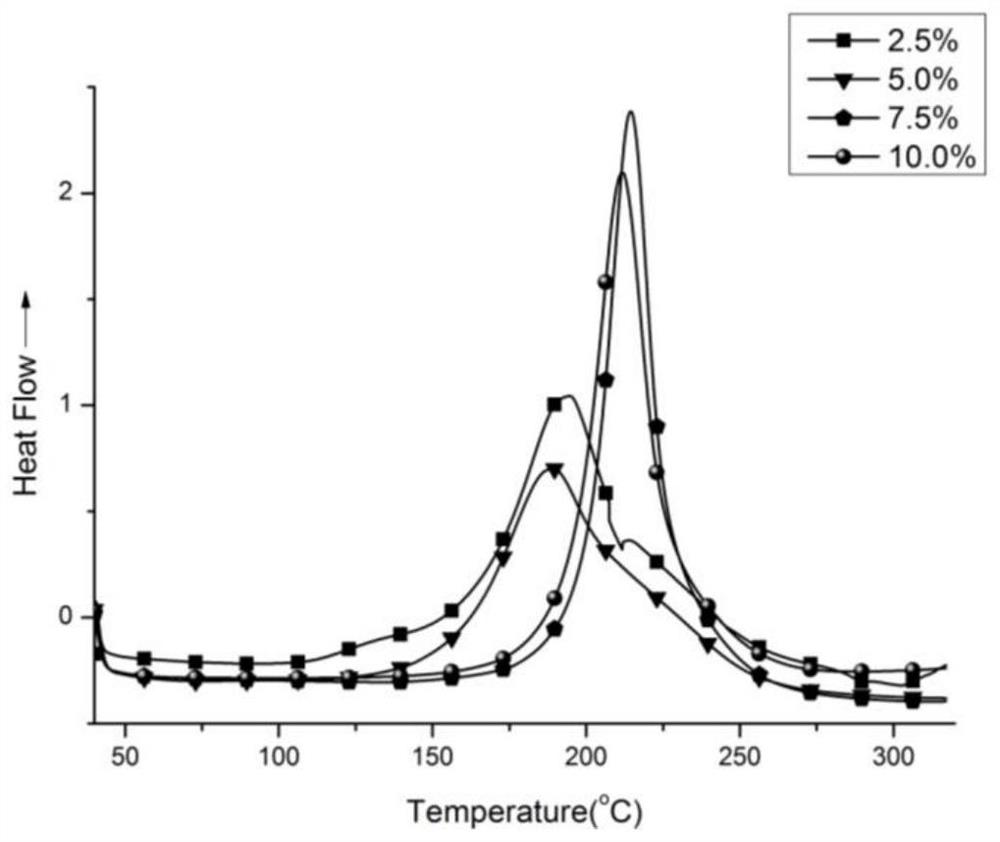

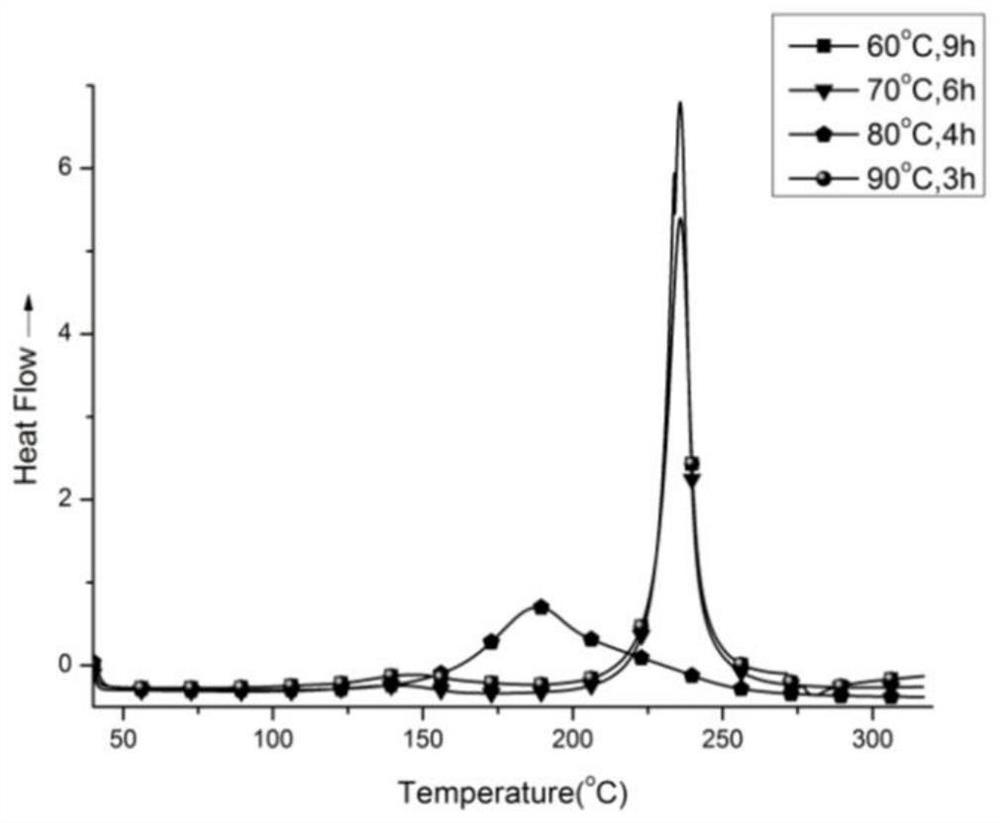

[0034] Add lignin, phenol, NaOH solution and an appropriate amount of water into a three-necked flask, reflux at a certain temperature for a period of time to obtain phenolized lignin, and use phenolized lignin to replace 5% phenol by mass fraction to prepare lignin-phenol-aniline Taking benzoxazine (5L-Pa) as an example, the effects of factors such as the mass ratio of lignin to phenol, the amount of NaOH, temperature and time on the phenolization of lignin were investigated by DSC. First, the effect of the mass ratio of lignin to phenol on phenolization was studied. The mass ratios of lignin to phenol were 1:1, 1:1.5, 1:2 and 1:2.5, respectively; The influence of the phenolization of lignin, the dosage of NaOH is 2.5%, 5.0%, 7.5% and 10.0% of the mass of lignin; finally, the influence of reaction temperature and time on the phenolization is investigated, the temperature and time are respectively 60 ℃ for 9h, 70°C for 6...

Embodiment 2

[0047] Embodiment 2: Preparation of lignin-hydroquinone-hexamethylenediamine type benzoxazine

[0048] Add paraformaldehyde and distilled water into a three-necked flask equipped with a condenser and a stirring device, adjust the pH value to about 8 with 4% sodium hydroxide, and stir at 60°C to dissolve all of it to obtain an aqueous formaldehyde solution. After the formaldehyde aqueous solution is cooled to room temperature, add hexamethylenediamine and dioxane; after reacting in an ice bath for 30 minutes, add hydroquinone, dioxane and ethanol, and when the temperature rises to 80°C, add phenolized lignin, The reaction was continued at 80° C. for 5 h to obtain a mixture of lignin-hydroquinone-hexamethylenediamine-type benzoxazine. Wherein, the ratio of the amount of the above-mentioned phenols (including hydroquinone and phenolated lignin), hexamethylenediamine and paraformaldehyde is 1:1:4, and the mass ratio of phenolated lignin to hydroquinone It is 3:97, that is, the re...

Embodiment 3

[0049] Embodiment 3: Preparation of lignin-cardanol-cyclohexylamine type benzoxazine

[0050] Add paraformaldehyde and distilled water into a three-neck flask equipped with a condenser and a stirring device, adjust the pH value to 9.0 with 4% sodium hydroxide, and stir at 65°C to completely dissolve it to obtain an aqueous formaldehyde solution. After the formaldehyde solution is cooled to room temperature, add cyclohexylamine and xylene; after reacting at room temperature for 30 minutes, add cardanol, xylene and ethanol, wait until the temperature rises to 80°C, add phenolated lignin, and continue the reaction at 80°C for 5 hours A lignin-cardanol-cyclohexylamine-type benzoxazine mixture is obtained. Wherein, the ratio of the amount of the above-mentioned phenols (comprising cardanol and phenolized lignin), cyclohexylamine and paraformaldehyde is 1:1:2, and the mass ratio of phenolized lignin to cardanol is 3:97 , that is, the substitution amount of phenolized lignin for phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com