Single-component composite silane modified polyether heat conductive adhesive and preparation method thereof

A technology of silane-modified polyether and composite silane, which is applied in the field of sealants, can solve the problems of inability to apply heat conduction to electronic appliances and insufficient heat conduction performance, and achieve high shear strength, improve mechanical properties, and improve heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

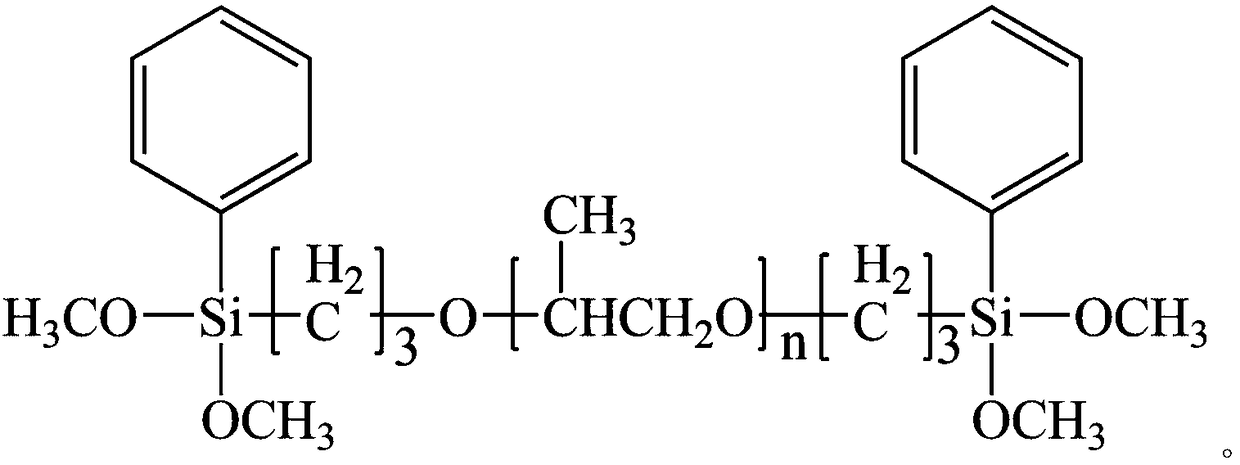

Method used

Image

Examples

Embodiment 1

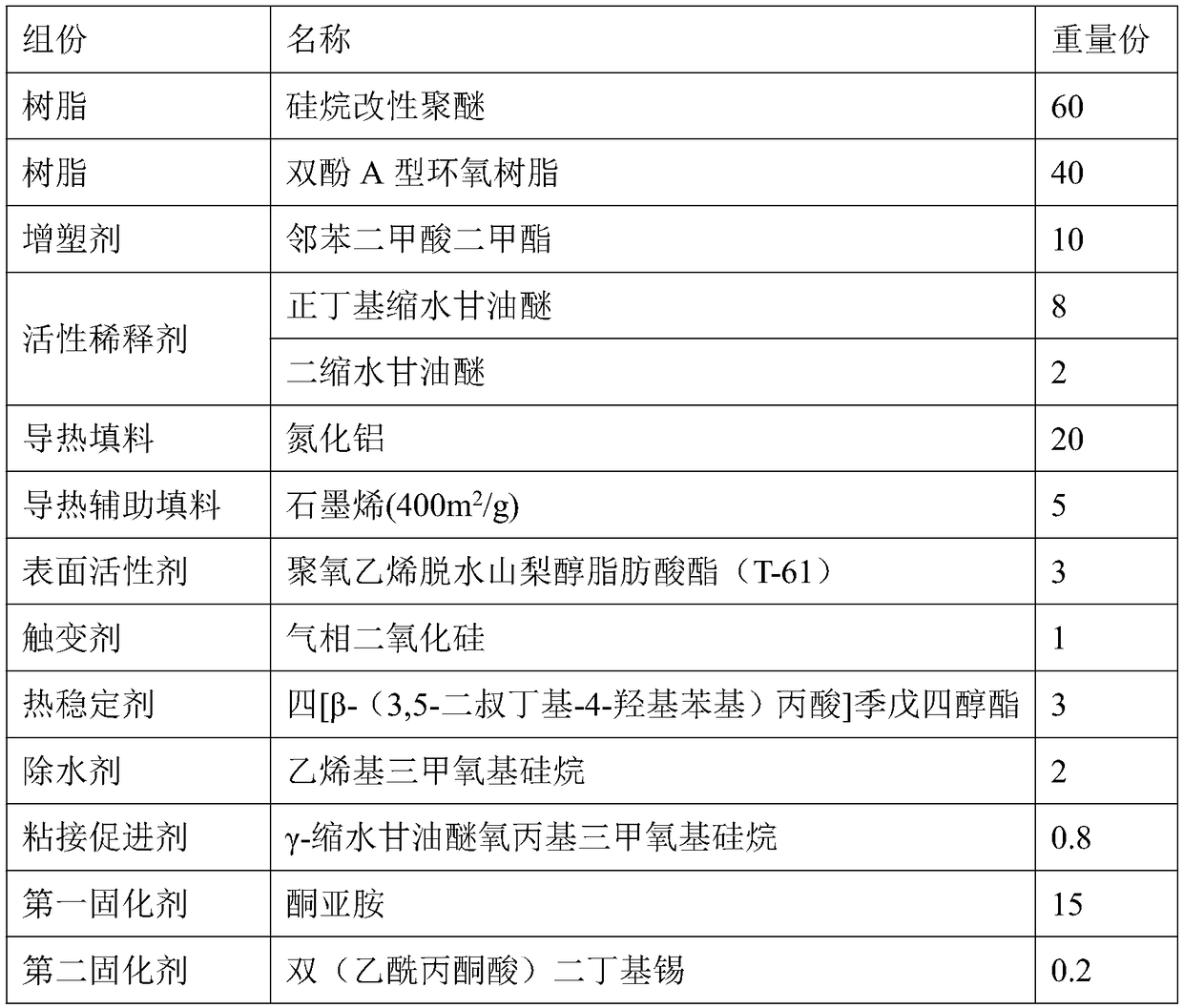

[0030] A one-component composite silane-modified polyether thermally conductive adhesive, comprising the following components in parts by weight:

[0031]

[0032] The preparation process steps of the thermally conductive adhesive are:

[0033] (1) The thermally conductive filler aluminum nitride and the thermally conductive auxiliary filler graphene (400m 2 / g) dried at 100°C for 3 hours and set aside;

[0034](2) the above-mentioned heat conduction auxiliary filler graphene (400m 2 / g), silane-modified polyether resin and surfactant polyoxyethylene sorbitan fatty acid ester are dispersed in a reactor at a high speed for 20-30 minutes, and then ultrasonicated at a power of 1000W for 40-80 minutes to obtain a mixed solution;

[0035] (3) the above mixed solution, epoxy resin bisphenol A type epoxy resin, thermally conductive filler aluminum nitride, plasticizer dimethyl phthalate, reactive diluent n-butyl glycidyl ether and diglycidyl ether , thixotropic agent fumed sili...

Embodiment 2

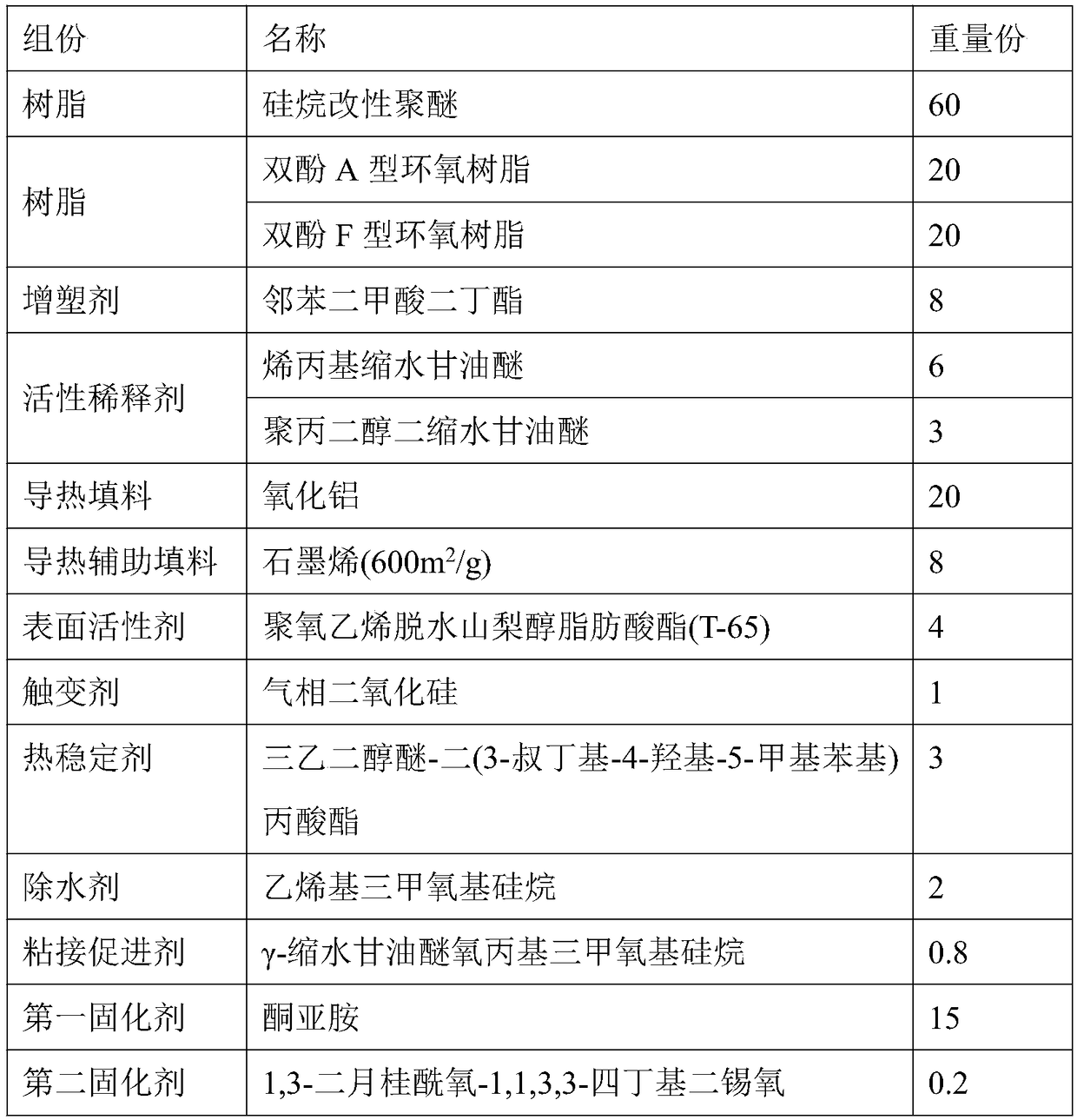

[0038] A one-component composite silane-modified polyether thermally conductive adhesive, comprising the following components in parts by weight:

[0039]

[0040] The preparation process steps of the thermally conductive adhesive are:

[0041] (1) The thermally conductive filler alumina and the thermally conductive auxiliary filler graphene (600m 2 / g) dried at 100°C for 3 hours and set aside;

[0042] (2) the above-mentioned heat conduction auxiliary filler graphene (600m 2 / g), silane-modified polyether resin and surfactant polyoxyethylene sorbitan fatty acid ester are dispersed in a reactor at a high speed for 20-30 minutes, and then ultrasonicated at a power of 1000W for 40-80 minutes to obtain a mixed solution;

[0043] (3) The above mixed solution, epoxy resin bisphenol A type epoxy resin and bisphenol F type epoxy resin, thermal conductive filler aluminum oxide, plasticizer dibutyl phthalate, reactive diluent allyl group Glycidyl ether and polypropylene glycol di...

Embodiment 3

[0046] A one-component composite silane-modified polyether thermally conductive adhesive, comprising the following components in parts by weight:

[0047]

[0048] The preparation process steps of the thermally conductive adhesive are:

[0049] (1) The thermally conductive filler aluminum nitride and alumina and the thermally conductive auxiliary filler graphene (500m 2 / g) dried at 100°C for 3 hours and set aside;

[0050] (2) the above-mentioned heat conduction auxiliary filler graphene (500m 2 / g), silane-modified polyether resin and surfactant polyoxyethylene sorbitan fatty acid ester are dispersed in a reactor at a high speed for 20-30 minutes, and then ultrasonicated at a power of 1000W for 40-80 minutes to obtain a mixed solution;

[0051] (3) the above-mentioned mixed solution, epoxy resin bisphenol A type epoxy resin, thermally conductive filler aluminum nitride and aluminum oxide, plasticizer dibutyl phthalate, reactive diluent vinyl n-butyl glycidyl ether and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com