Carbon spot based photo-thermal conversion material preparation method

A technology of light-to-heat conversion and carbon dots, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high preparation cost, low evaporation rate and low solar conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

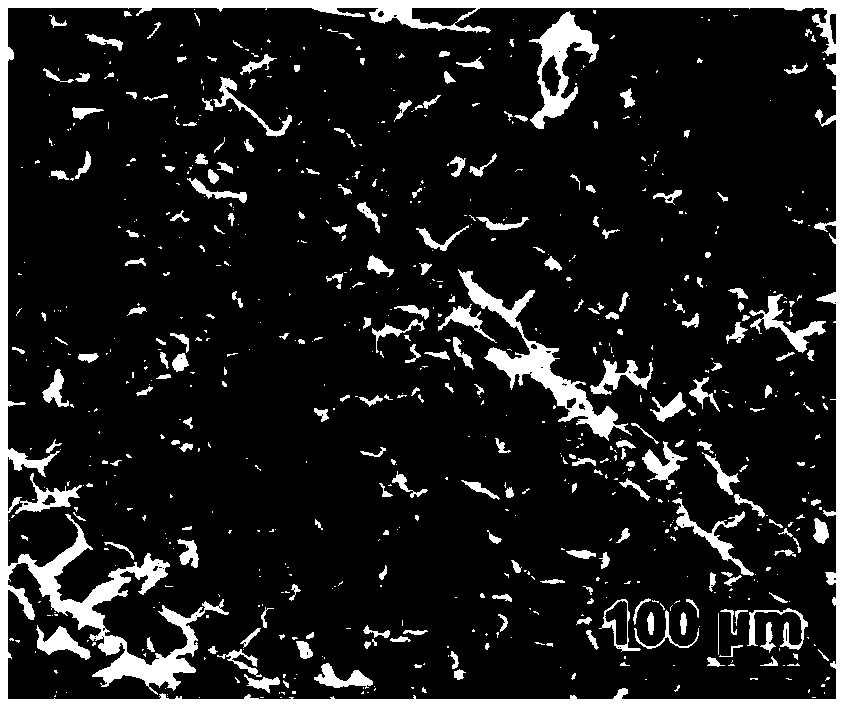

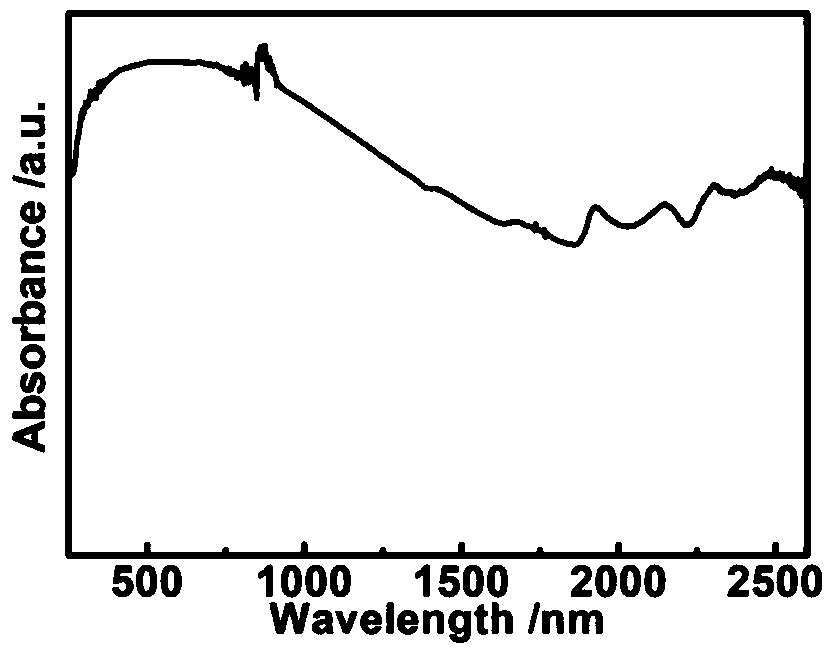

Image

Examples

preparation example Construction

[0023] A preparation method of a carbon dot-based light-to-heat conversion material adopts the following steps:

[0024] Step 1 Process the dried wood into wood chips with a thickness of 5-6 mm along the vertical growth direction, then put the wood chips into 0.8-1.3 mol / L sodium hypochlorite solution, soak at 30-40 ° C for 60-80 min;

[0025] Step 2 configures a mixed solution of sodium hydroxide and hydrogen peroxide, the concentration of sodium hydroxide in the mixed solution is 1.2-2.0mol / L, and the concentration of hydrogen peroxide is 3.4-4.0mol / L;

[0026] Step 3 immerse the wood chips treated in step 1 into the mixed solution prepared in step 2, and use 28KHz ultrasonic treatment at 70-85°C for 60-80min;

[0027] Step 4 Take out the wood chips treated in step 3, put them into deionized water at room temperature and clean them with 28KHz ultrasonic waves, measure the pH value of the deionized water after cleaning, replace with new deionized water, and wash them several ...

Embodiment 1

[0038] A preparation method of a carbon dot-based light-to-heat conversion material adopts the following steps:

[0039] Step 1 Process the dry wood into wood chips with a thickness of 5mm along the vertical growth direction, then put the wood chips into 1mol / L sodium hypochlorite solution, and soak them at 40°C for 70 minutes;

[0040] Step 2 configures the mixed solution of sodium hydroxide and hydrogen peroxide, the concentration of sodium hydroxide in the mixed solution is 1.5mol / L, and the concentration of hydrogen peroxide is 3.6mol / L;

[0041] Step 3: immerse the wood chips treated in step 1 into the mixed solution prepared in step 2, and use 28KHz ultrasonic treatment at 80°C for 70 minutes;

[0042] Step 4 Take out the wood chips treated in step 3, put them into deionized water at room temperature and clean them with 28KHz ultrasonic waves, measure the pH value of the deionized water after cleaning, replace with new deionized water, and wash them several times until a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com