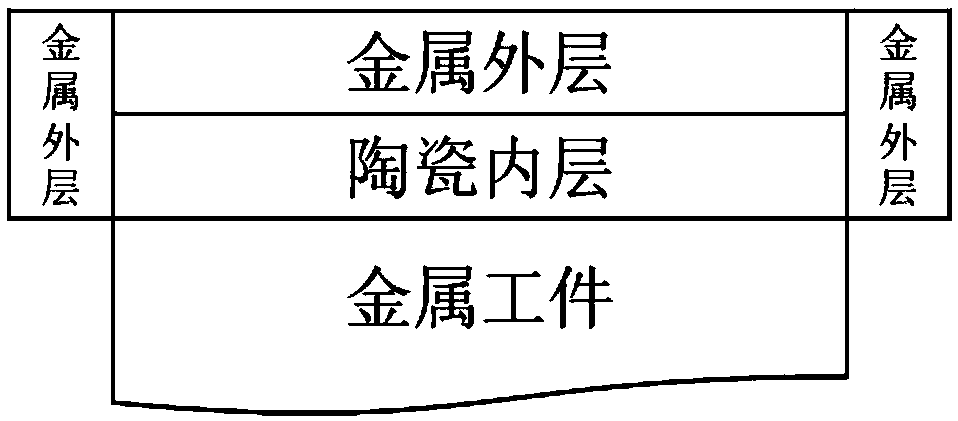

Metal workpiece double layer coating suitable for high temperature environment and manufacturing method thereof

A metal workpiece, double-layer coating technology, applied in the direction of metal material coating process, coating, fusion spraying, etc., to achieve the effect of changing mechanical properties and reducing high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The sample preparation method of embodiment 1 is as follows:

[0043] (1) Mechanical (or chemical) treatment of the workpiece surface

[0044] Put the steel workpiece in a beaker filled with degreasing liquid, and put it into an ultrasonic field at a frequency of 30kHz to degrease. Then put it into the sandblasting machine for coarsening, adjust the working pressure of the compressed air of the sandblasting machine at 0.7MPa, the spray angle is controlled at 50°, the distance between the nozzle and the working surface is controlled at 150mm, and the surface roughness of the workpiece after sandblasting is 80μm . Then put it into the ultrasonic field at a frequency of 30kHz and clean it again.

[0045] (2) Thermal spraying on the surface of the workpiece

[0046]Preheat the pretreated workpiece to 200°C, and use atmospheric plasma spraying equipment to spray the inner layer of zirconia ceramics on the surface of the workpiece. The parameters for spraying the inner lay...

Embodiment 2

[0052] The sample preparation method of embodiment 2 is as follows:

[0053] (1) Mechanical (or chemical) treatment of the workpiece surface

[0054] Put the steel workpiece in a beaker filled with degreasing liquid, and put it into an ultrasonic field at a frequency of 40kHz to degrease. Then put it into the sandblasting machine for coarsening, adjust the working pressure of the compressed air of the sandblasting machine at 0.4MPa, the spray angle at 30°, the distance between the nozzle and the working surface at 100mm, and the surface roughness of the workpiece after sandblasting at 100μm . Then put it into the ultrasonic field at a frequency of 40kHz and clean it again.

[0055] (2) Thermal spraying on the surface of the workpiece

[0056] Preheat the pretreated workpiece to 200°C, and use atmospheric plasma spraying equipment to spray the inner layer of zirconia ceramics on the surface of the workpiece. The parameters for spraying the inner layer of zirconia ceramics ar...

Embodiment 3

[0062] The sample preparation method of embodiment 3 is as follows:

[0063] (1) Mechanical (or chemical) treatment of the workpiece surface

[0064] Put the nickel alloy workpiece in a beaker filled with degreasing liquid, and put it into an ultrasonic field at a frequency of 35kHz to degrease. Then put it into the sandblasting machine for coarsening, adjust the working pressure of the compressed air of the sandblasting machine at 0.8MPa, the spray angle is controlled at 60°, the distance between the nozzle and the working surface is controlled at 200mm, and the surface roughness of the workpiece after sandblasting is 60μm . Then put it into the ultrasonic field at a frequency of 35kHz and clean it again.

[0065] (2) Thermal spraying on the surface of the workpiece

[0066] Preheat the pretreated workpiece to 200°C, and use atmospheric plasma spraying equipment to spray the inner layer of gadolinium zirconate ceramics on the surface of the workpiece. The parameters for sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com