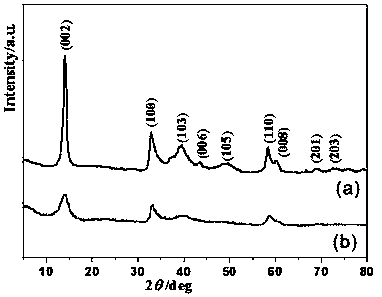

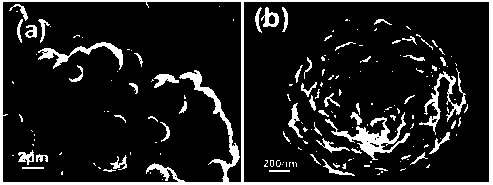

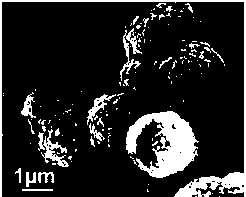

Molybdenum disulfide/nitrogen doped carbon composite material and preparation method and application thereof

A technology of nitrogen-doped carbon and molybdenum disulfide, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of unstable structure and poor conductivity of molybdenum disulfide, so as to improve the conductivity and structural stability and improve the preparation process. The effect of simplicity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] S1. Dissolve 16.74 mmol of galactosamine in 60 mL of deionized water under stirring to form a solution, and adjust the pH value of the solution to 5 with concentrated hydrochloric acid;

[0071] S2. Add 0.215 mmol of ammonium molybdate and 9 mmol of thiourea under stirring. After all dissolved, the molar ratio of molybdenum atoms in galactosamine and ammonium molybdate in the solution is 11.1:1, the molar ratio of molybdenum atoms in thiourea and ammonium molybdate is 6:1, and the concentration of galactosamine is 0.28 mol / L;

[0072] S3. Transfer this solution to a 100 mL stainless steel reactor lined with polytetrafluoroethylene. Placed in a dry box, hydrothermally reacted at 220°C for 24 hours. Then cool naturally to room temperature, rinse with deionized water and absolute ethanol three times respectively, centrifuge and vacuum dry at 60°C for 12 hours to obtain a hydrothermal product;

[0073] S4. Put a certain amount of hydrothermal product in a porcelain boat...

Embodiment 2

[0075] The difference between this embodiment and Example 1 is that the mol ratio of molybdenum atoms in galactosamine and ammonium molybdate in the solution of this embodiment is 9.3: 1, and the mol ratio of molybdenum atoms in thiourea and ammonium molybdate is 5: 1. The concentration of galactosamine is 0.23 mol / L, the pH value is 4, and the calcination temperature is 800 ℃;

[0076] Other conditions and operation steps are identical with embodiment 1.

Embodiment 3

[0078] The difference between this embodiment and Example 1 is that the mol ratio of molybdenum atoms in galactosamine and ammonium molybdate in the solution of the present embodiment is 7.4: 1, and the mol ratio of molybdenum atoms in thiourea and ammonium molybdate is 5: 1. The concentration of galactosamine is 0.19 mol / L, the pH value is 3, the temperature of hydrothermal reaction is 200 ℃, and the temperature of calcination is 800 ℃;

[0079] Other conditions and operation steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com