A continuous production process for synthesizing hexahydrophthalic anhydride in a mixed solvent

A mixed solvent and hexahydrophthalic anhydride technology, applied in the direction of organic chemistry, can solve the problems of low production efficiency, difficult solvent removal, high impurity content, etc., and achieve the effects of improved production efficiency, difficult separation and removal, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be further elaborated in conjunction with specific embodiments.

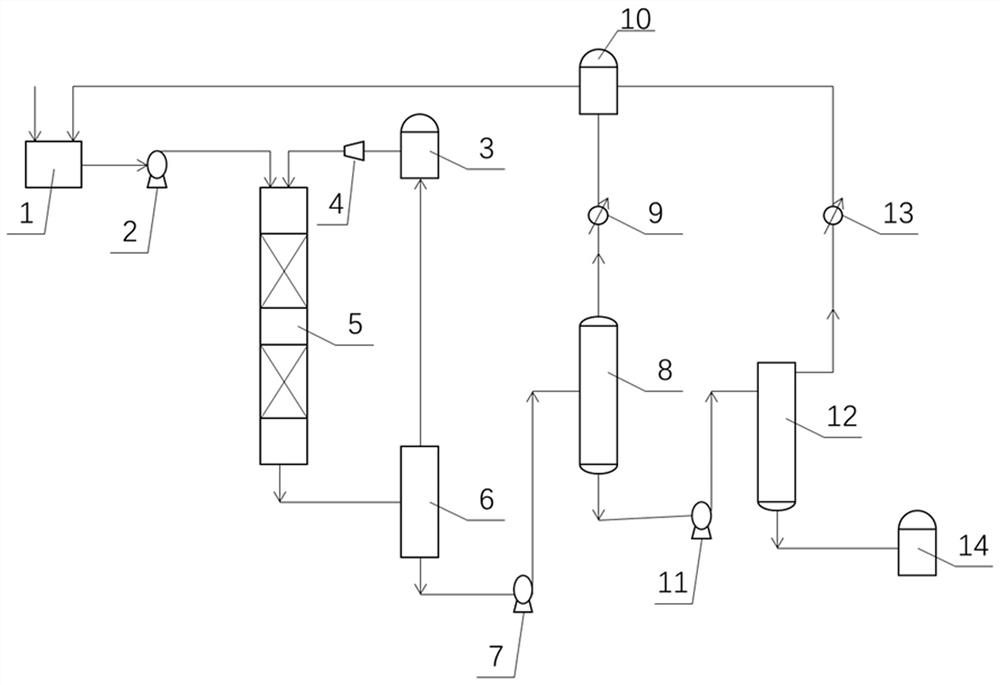

[0024] figure 1 For the process flow diagram of the present invention, firstly, the catalyst is fixed on the fixed-bed reactor, and the NiO / SiO2 catalyst is loaded on the fixed-bed reactor 5 . First replace the reaction system with nitrogen to make the oxygen content lower than 0.2% (volume), then switch to hydrogen for catalyst reduction, control the volume space velocity of hydrogen feed to 2000h-1, reactor temperature 130°C, pressure 3.0Mpa, reduction 24h .

[0025] Carry out hydrogenation reaction then, THF and hexanaphthene are formulated as mixed solvent in solvent tank by volume ratio 5:1, tetrahydrophthalic anhydride and mixed solvent are dropped into batching tank 1 by mass ratio 1:4, pass through the first circulation pump 2 into the fixed-bed reactor 5 equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com