Preparation method of chemically-crosslinking-foamed polyethylene material, and screw rod

A foamed polyethylene and chemical cross-linking technology, applied in the screw field of a single-screw extruder, can solve the problems of lower melt strength, lower melting point, difficult process control, etc., and achieve good strength and impact resilience, product performance. Excellent and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The polyethylene material formulation includes the following components (mass parts)

[0039]

[0040]

[0041] After each component in the polyethylene material formula is mixed uniformly in a high-speed mixer (rotating speed 200rpm), it is extruded through a single-screw extruder, and then enters a mold for molding.

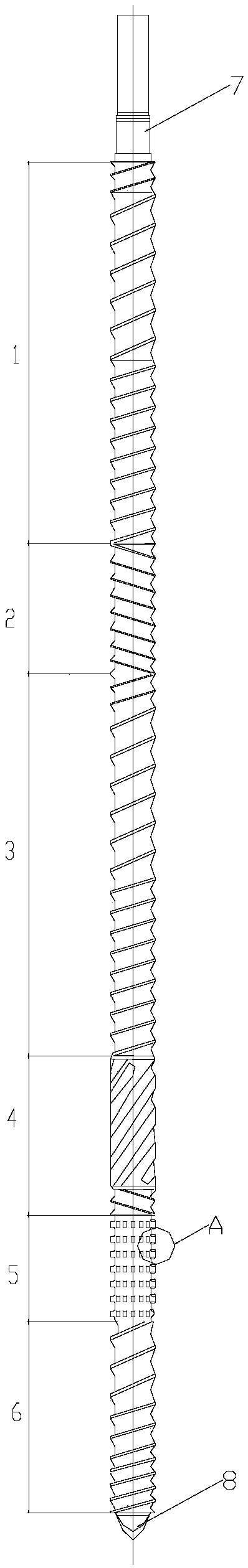

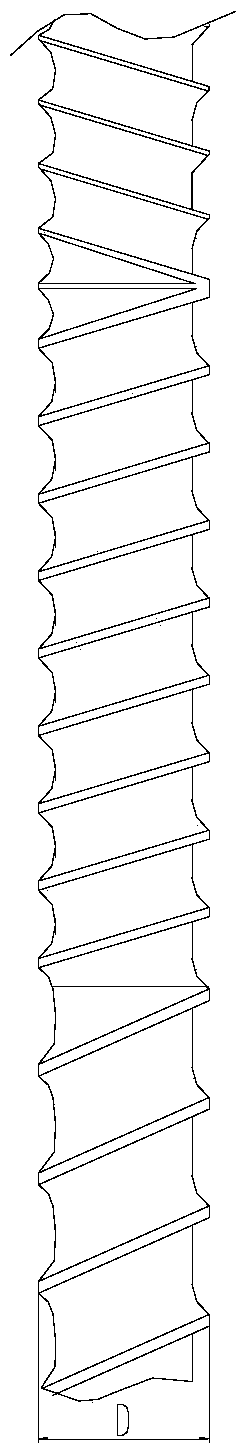

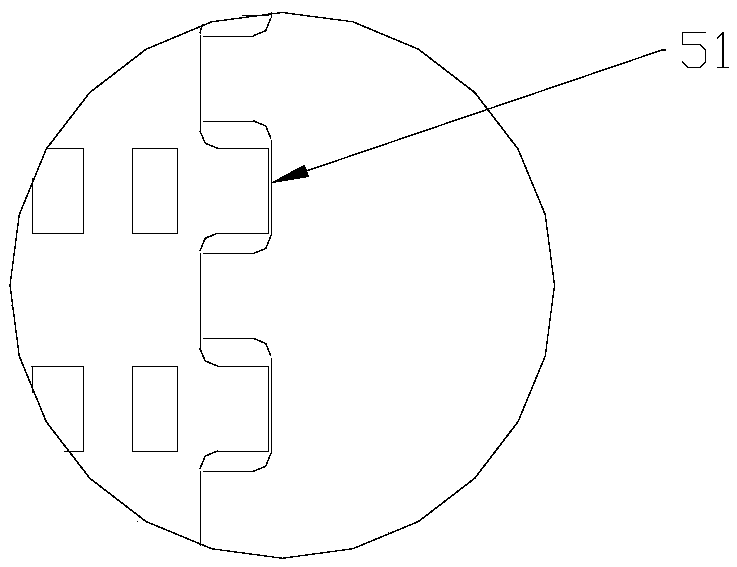

[0042] Among them, the single-screw extruder chooses Zhejiang Shuanglin Φ60mm single-screw extruder, and the structural diagram of the screw is as follows figure 1 The shown screw has an aspect ratio of 36. The screw includes a screw head 7 and a screw tail 8 , and a screw working section connected between the screw head 7 and the tail 8 . The end of the screw working section close to the screw head is the head end, and the end close to the tail of the screw is the tail end. The screw working section includes the first positive direction connected in sequence from the head end to the tail end (that is, along the direction in which the material is c...

Embodiment 2

[0048] The polyethylene material formulation includes the following components (mass parts)

[0049]

[0050] After each component in the polyethylene material formula is mixed uniformly in a high-speed mixer (rotating speed 200rpm), it is extruded through a single-screw extruder, and then enters a mold for molding.

[0051] The selected single-screw extruder is the same as that of Example 1, the screw structure is the same as that of Example 1, and will not be described again, and the aspect ratio is 36.

[0052] The working temperature of the screw is set as follows: the first forward screw conveyor section is 120°C, the reverse screw conveyor section is 140°C, the second forward screw conveyor section is 140°C, the reverse kneading section is 150°C, the mixing section is 160°C, and the third 160°C to the screw conveying section. The mold temperature is set at 160° C.; the screw speed is 70 rpm.

[0053] The obtained product performance test is shown in the following ta...

Embodiment 3

[0057] The polyethylene material formulation includes the following components (mass parts)

[0058]

[0059]

[0060] After each component in the polyethylene material formula is mixed uniformly in a high-speed mixer (rotating speed 200rpm), it is extruded through a single-screw extruder, and then enters a mold for molding.

[0061] The selected single-screw extruder is the same as that of Example 1, and the screw structure is basically the same as that of Example 1. The only difference is that the first forward thread delivery section, the reverse thread delivery section, the second forward thread delivery section, the reverse The lengths to the kneading section, the mixing section and the third forward screw conveying section are respectively 9D, 5D, 10D, 5D, 3D, and 7D of the screw diameter D of the screw working section; the length-to-diameter ratio of the screw is 30.

[0062] The working temperature of the screw is set as follows: the first forward screw conveyor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com