Carbon nanotube/hydrotalcite material for removal of nitrate nitrogen from water and preparation method

A carbon nanotube and multi-wall carbon nanotube technology, which can be applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as unsatisfactory removal effect, and achieve good removal effect. , reduce electronegativity, and promote the effect of adsorption and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

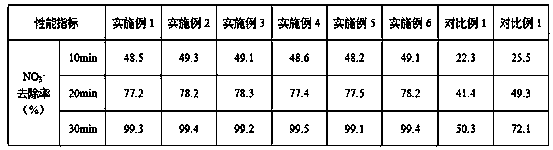

Examples

Embodiment 1

[0027] (1) Add magnesium nitrate hexahydrate, aluminum nitrate nonahydrate, and lanthanum nitrate hexahydrate into deionized water to obtain solution A; add sodium carbonate and sodium hydroxide to deionized water to obtain solution B; in solution A, nitric acid hexahydrate 11 parts by weight of magnesium, 9 parts by weight of aluminum nitrate nonahydrate, 2 parts by weight of lanthanum nitrate hexahydrate, 78 parts by weight of deionized water; in solution B, 7 parts by weight of sodium carbonate, 4 parts by weight of sodium hydroxide, and 89 parts by weight of deionized water share;

[0028] (2) Disperse the multi-walled carbon nanotubes in deionized water, and heat the dispersion, then drop solution A and solution B into the multi-walled carbon nanotubes dispersion at the same time, stir vigorously to react, and then let it stand for 3.5h, Generate a lanthanum-doped hydrotalcite layer on the tube wall of the multi-walled carbon nanotubes; the parts by weight of each raw mat...

Embodiment 2

[0031] (1) Add magnesium nitrate hexahydrate, aluminum nitrate nonahydrate, and lanthanum nitrate hexahydrate into deionized water to obtain solution A; add sodium carbonate and sodium hydroxide to deionized water to obtain solution B; in solution A, nitric acid hexahydrate 10 parts by weight of magnesium, 8 parts by weight of aluminum nitrate nonahydrate, 2 parts by weight of lanthanum nitrate hexahydrate, 80 parts by weight of deionized water; in solution B, 6 parts by weight of sodium carbonate, 4 parts by weight of sodium hydroxide, and 90 parts by weight of deionized water share;

[0032] (2) Disperse the multi-walled carbon nanotubes in deionized water, and heat the dispersion, then drop solution A and solution B into the multi-walled carbon nanotubes dispersion at the same time, stir vigorously to react, and then stand for 3 hours, A hydrotalcite layer doped with lanthanum is generated on the tube wall of the multi-walled carbon nanotube; the parts by weight of each raw...

Embodiment 3

[0035](1) Add magnesium nitrate hexahydrate, aluminum nitrate nonahydrate, and lanthanum nitrate hexahydrate into deionized water to obtain solution A; add sodium carbonate and sodium hydroxide to deionized water to obtain solution B; in solution A, nitric acid hexahydrate 12 parts by weight of magnesium, 9 parts by weight of aluminum nitrate nonahydrate, 3 parts by weight of lanthanum nitrate hexahydrate, 76 parts by weight of deionized water; in solution B, 7 parts by weight of sodium carbonate, 5 parts by weight of sodium hydroxide, and 88 parts by weight of deionized water share;

[0036] (2) Disperse the multi-walled carbon nanotubes in deionized water, and heat the dispersion, then drop solution A and solution B into the multi-walled carbon nanotubes dispersion at the same time, stir vigorously to react, and then let stand for 4 hours, A hydrotalcite layer doped with lanthanum is generated on the tube wall of the multi-walled carbon nanotube; the parts by weight of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com