Method for preparing nano starch granules by combining biological enzyme and alkali freezing technology

A nano-starch and bio-enzyme technology, which is applied in the field of preparation of nano-starch granules, can solve the problems of difficult operation, high environmental requirements, and large product particle size changes, and achieve the effects of reducing production costs, low environmental requirements, and uniform granules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

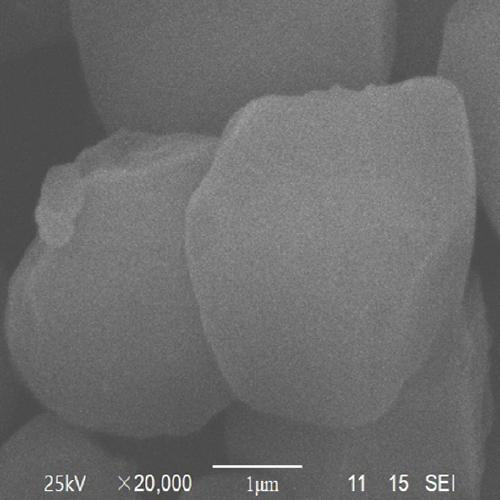

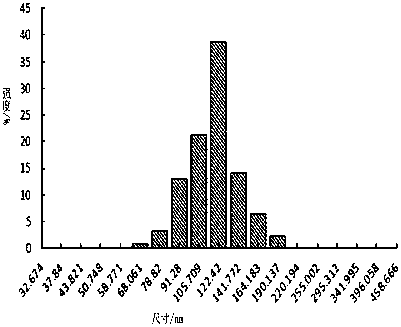

Embodiment 1

[0034] (1) Dissolve 5g of rice starch in 100mL of distilled water to make a 5% starch suspension;

[0035] (2) Heat and stir the starch suspension in step (1) in a boiling water bath at 70°C for 15 minutes to gelatinize to form a starch solution;

[0036] (3) Dissolve 2.21 g of disodium hydrogen phosphate and 0.75 g of citric acid in 100 mL of distilled water, mix thoroughly to prepare a buffer, use the prepared buffer to adjust the starch solution in step (2) to a pH of 4.5, and add 6u / g of α-amylase, hydrolyzed in a constant temperature water bath at 50°C for 5 hours, centrifuged at 4000r / min for 15 minutes, washed and precipitated with ethanol for 3 times, and freeze-dried in a vacuum freeze dryer to obtain short amylose;

[0037] (4) Add short amylose in step (3) to 100mL urea / sodium hydroxide / distilled water with a mass ratio of 6:2:100, and mechanically stir for 3 hours at 500r / min;

[0038] (5) Freezing: freeze at -20°C for 24 hours;

[0039] (6) Thawing: thaw at roo...

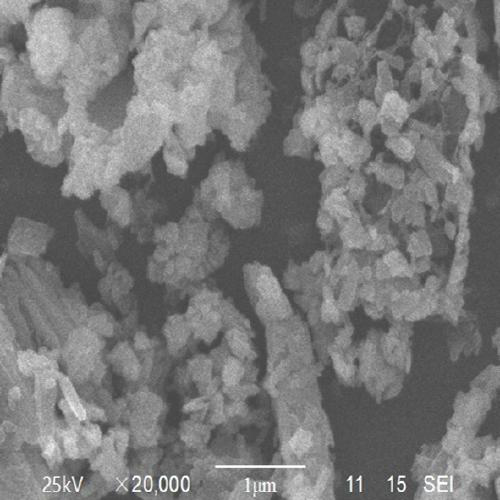

Embodiment 2

[0046] (1) Dissolve 2g of rice starch in 100mL of distilled water to make a 2% starch suspension;

[0047] (2) Heat and stir the starch suspension in step (1) in a boiling water bath at 100°C for 20 minutes to gelatinize to form a starch solution;

[0048] (3) Dissolve 1.8g of citric acid and 0.41g of sodium citrate in 100mL distilled water to form a buffer, use the buffer to adjust the starch solution in step (2) to pH 5, add 12u / g pullulanase, Hydrolyze in a water bath at 50°C for 8 hours, centrifuge at 4000r / min for 15 minutes, wash the precipitate with ethanol 4 times, and vacuum freeze-dry to obtain short amylose;

[0049] (4) Add short amylose in step (3) to 100mL urea / sodium hydroxide / distilled water with a mass ratio of 6:4:100, and mechanically stir for 3 hours at 800r / min;

[0050] (5) Freezing: freeze at -80°C for 48 hours;

[0051] (6) Thawing: thaw at room temperature until completely thawed, and continue mechanical stirring at 400r / min for 40min;

[0052] (7) ...

Embodiment 3

[0055] (1) Dissolve 10g of rice starch in 100mL of distilled water to make a 10% starch suspension;

[0056] (2) Heat and stir the starch suspension in step (1) in a boiling water bath at 100°C for 10 minutes to gelatinize to form a starch solution;

[0057] (3) Dissolve 2.1g of citric acid, 0.83g of sodium hydroxide, and 1.06mL of commercially available concentrated hydrochloric acid in 100mL of distilled water to form a buffer. Use this buffer to adjust the starch solution in step (2) to a pH of 5.5, and add 8u / g of β-amylase, hydrolyzed in a water bath at 50°C for 5h, centrifuged at 4000r / min for 15min, washed and precipitated with ethanol 3 times, and vacuum freeze-dried to obtain short amylose;

[0058] (4) Add short amylose in step (3) to 100mL of urea / sodium hydroxide / distilled water solution with a mass ratio of 4:4:100, and mechanically stir for 2 hours at 500r / min;

[0059] (5) Freezing: freeze at -60°C for 36 hours;

[0060] (6) Thawing: thaw at room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com