A kind of single-ion-doped white fluorescent powder applied to WLED devices and preparation method thereof

A fluorescent powder and single-ion technology, which is applied in the field of new single-ion activated white phosphor and its preparation, can solve the problems of low fluorescence efficiency, poor chemical stability, harsh synthesis conditions, etc., and achieve high luminous intensity and good color stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

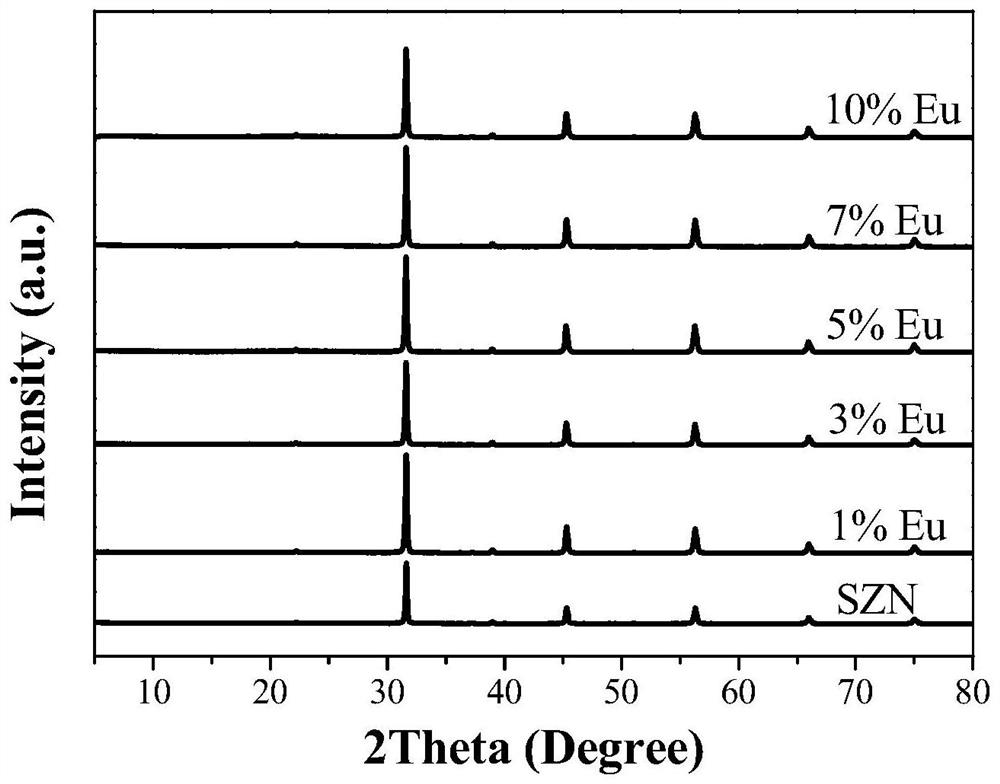

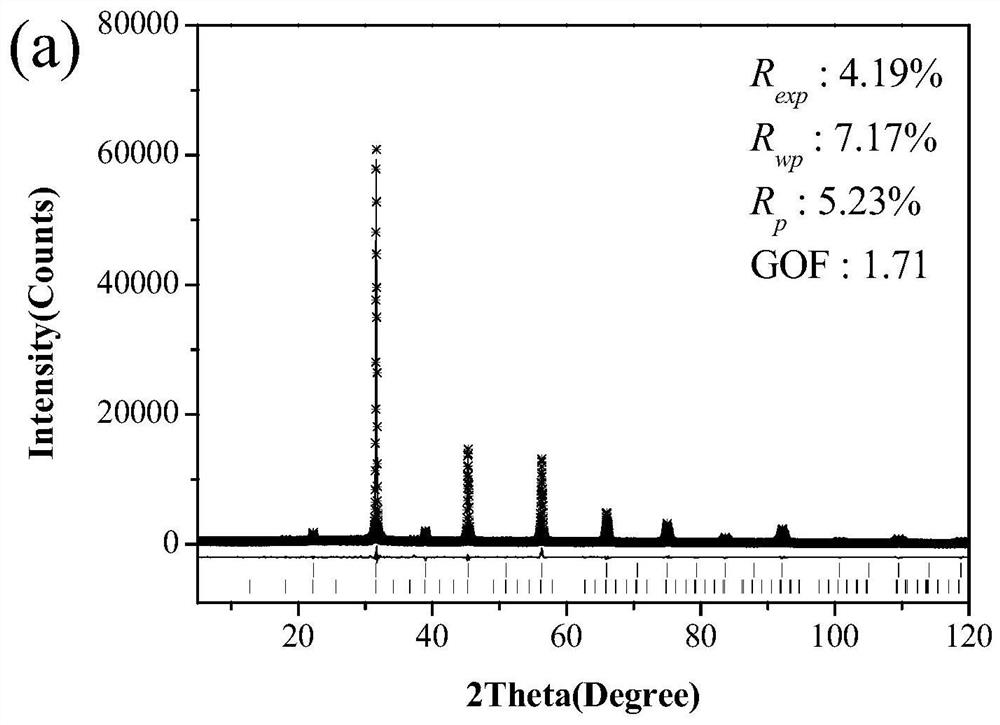

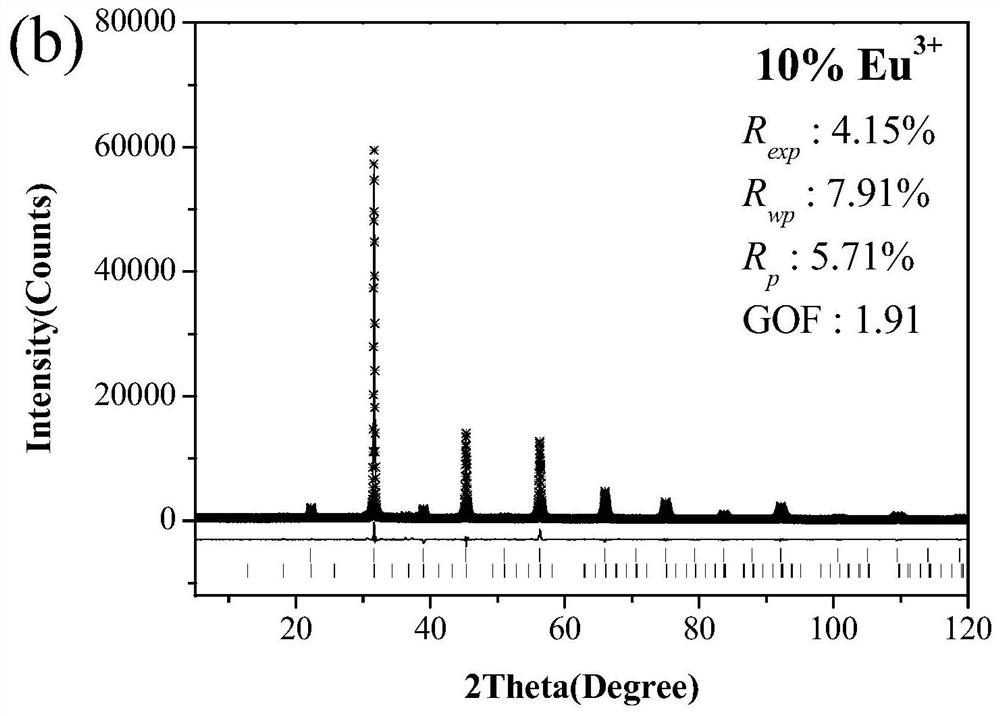

Embodiment 1

[0027] Weigh barium carbonate (BaCO 3 )0.5811g, Tan oxide (Ta 2 o 5 )0.4487g, europium oxide (Eu 2 o 3 ) 0.01786g, zinc oxide (ZnO) 0.0826g. Grind the above-mentioned raw materials in an agate mortar, put them into a corundum crucible after grinding evenly, and carry out the first step of sintering in an air atmosphere at 800°C, and the constant temperature time is 10h. After the end, take out the grinding, and then carry out the second step of sintering in an air atmosphere at 1100°C, and the constant temperature time is 10h. After the end, take out the grinding, and carry out the third step of sintering at 1100°C again, and the constant temperature time is 10h. After the third step is finished, wait for it to cool naturally, grind evenly and obtain the product. Product X-ray powder diffraction results such as figure 1 shown. Refined by Rietveld ( Figure 2a and Figure 2b ) further shows that the preparation scheme of multi-step sintering will not affect the phase. ...

Embodiment 2

[0029] Calcium carbonate (SrCO 3 ) 0.5093g, Tan oxide (Ta 2 o 5 )0.5257g, europium oxide (Eu 2 o 3 ) 0.0209g, and zinc oxide (ZnO) 0.0968g. Grind the above raw materials in an agate mortar, put them into a corundum crucible after grinding evenly, and carry out the first step of sintering in a reducing atmosphere at 800 ° C. The constant temperature time is 10 h. After the end, take out the grinding, and then carry out the second step of sintering in an air atmosphere at 1100°C, and the constant temperature time is 10h. After the end, take out the grinding, and carry out the third step of sintering at 1100°C again, and the constant temperature time is 10h. After the third step is finished, wait for it to cool naturally, grind evenly and obtain the product. All diffraction peaks are basically the same as those in the standard peak card (PDF#17-0177), indicating that the introduction of europium ions will not significantly affect the original phase. The fluorescence emissio...

Embodiment 3

[0031] Strontium carbonate (SrCO 3 )0.6282g, niobium oxide ((Nb 2 o 5 )0.4039g, europium oxide (Eu 2 o 3 ) 0.0267g, zinc oxide (ZnO) 0.1237g. Grind the above raw materials in an agate mortar, put them into a corundum crucible after grinding evenly, and carry out the first step of sintering in an air atmosphere at 800°C, and the constant temperature time is 10h. After the end, take out the grinding, and then carry out the second step of sintering in an air atmosphere at 1100°C, and the constant temperature time is 10h. After the end, take out the grinding, and carry out the third step of sintering at 1100°C again, and the constant temperature time is 10h. After the third step is finished, wait for it to cool naturally, grind evenly and obtain the product. Product X-ray powder diffraction results such as figure 1 shown. Such as figure 1 As shown in the middle line 1, all the diffraction peaks can correspond to the standard peak card (PDF#17-0177), which further shows tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com