Ultraviolet light blocking agent and anti-UV treatment process of nylon skin clothing fabric using ultraviolet blocking agent

A technology of nylon fabric and treatment process, which is applied in the direction of fiber treatment, biochemical fiber treatment, improved hand feeling fiber, etc. It can solve the problems of no antibacterial agent and poor antibacterial performance, and achieve good UV resistance, improved tear strength, and antibacterial Good effect and anti-ultraviolet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of ultraviolet blocking agent, is made up of the material of following parts by weight: 68 parts of modified polyurethanes, 5 parts of antibacterial agents, 4 parts of 2-hydroxyl-4-methoxybenzophenone, nano zinc oxide powder 2 2 parts, 2 parts of nano-titanium dioxide powder, 5 parts of mineral spirits, 3 parts of TDI trimer curing agent, 2 parts of polyethylene glycol, 3 parts of anionic amino silicone oil emulsion, 2 parts of waterproofing agent; wherein the antibacterial agent includes the following components by weight Ingredients: 20 parts of silver sulfonate, 12 parts of polyhexamethylene biguanide hydrogen chloride, 5 parts of aloe vera juice, 6 parts of octadecyl dimethyl ammonium chloride;

[0039] The modified polyurethane is prepared by the following method: 90 parts of polyurethane are dissolved in an aromatic solvent, and 0.3 parts of ammonium sulfate and 10 parts of acrylate are added thereto, heated to 60 ° C, and refluxed for 1 hour; ...

Embodiment 2-6

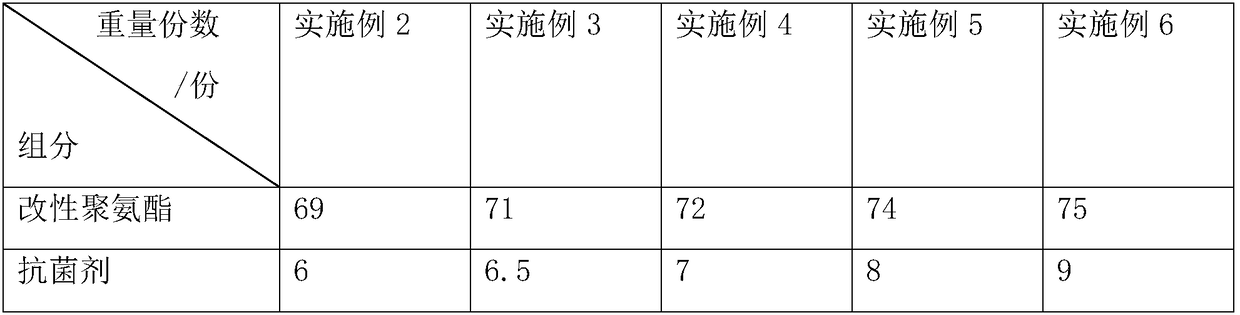

[0048] Example 2-6: An ultraviolet blocking agent, the difference from Example 1 is that the components contained and the parts by weight corresponding to the components are shown in Table 1.

[0049] Table 1 embodiment 2-6 comprises the component and the corresponding parts by weight of component

[0050]

[0051]

Embodiment 7-13

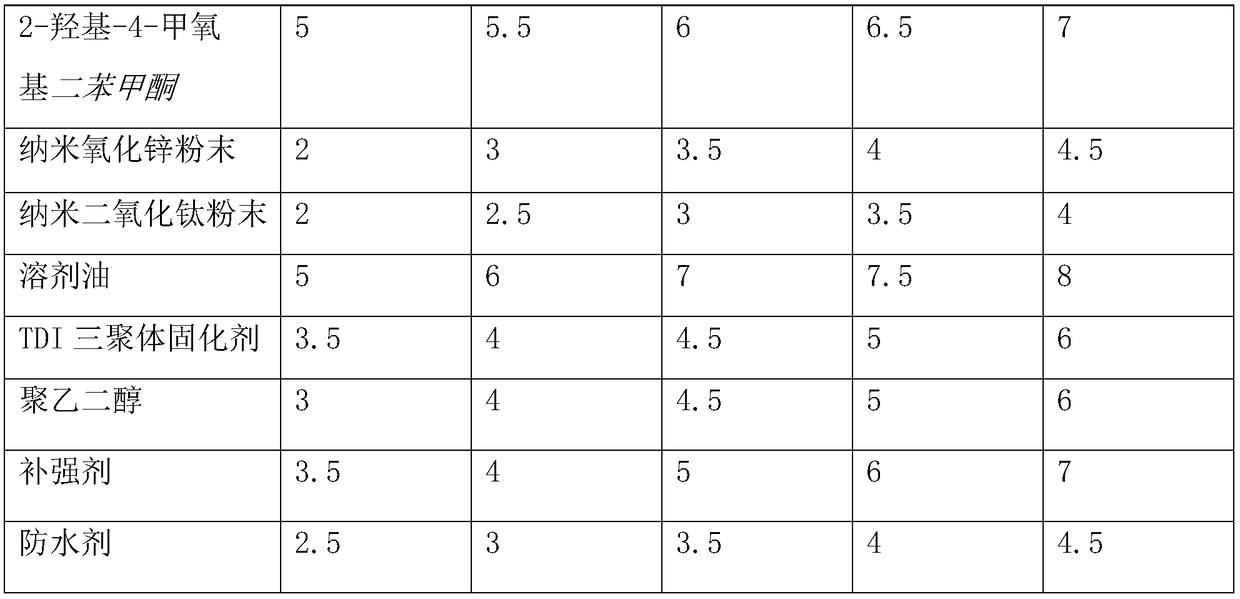

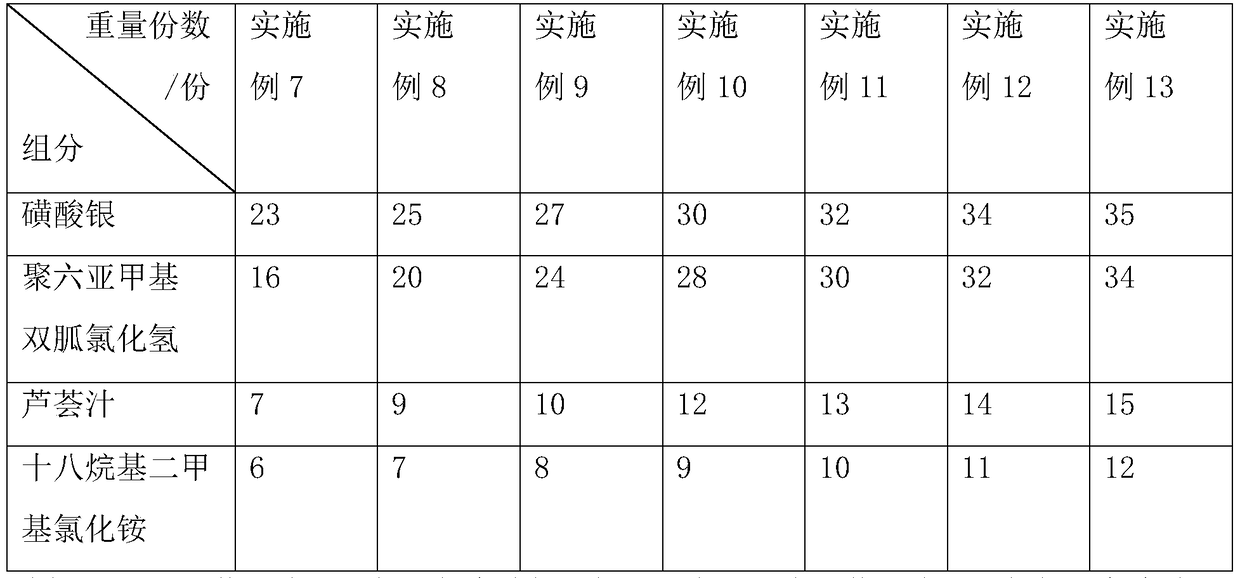

[0052] Embodiment 7-13: An ultraviolet blocking agent, the difference from Embodiment 1 is that the components contained in the antibacterial agent and the parts by weight corresponding to each component are shown in Table 2.

[0053] Components and corresponding parts by weight of antibacterial agent in table 2 embodiment 7-13

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com