Preparation method of high-quality octocrilene sun-screening agent

A technology of octocrylene and sunscreen, which is applied to the preparation of organic compounds, carboxylic acid nitrile preparation, chemical instruments and methods, etc., can solve the problems that affect the use of octocrylene, the product has deep color and low quality, and achieves Easy to control and industrialized production, convenient for industrialization, and the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

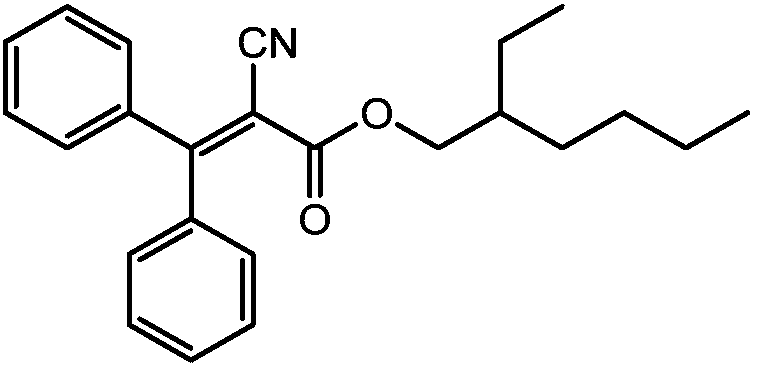

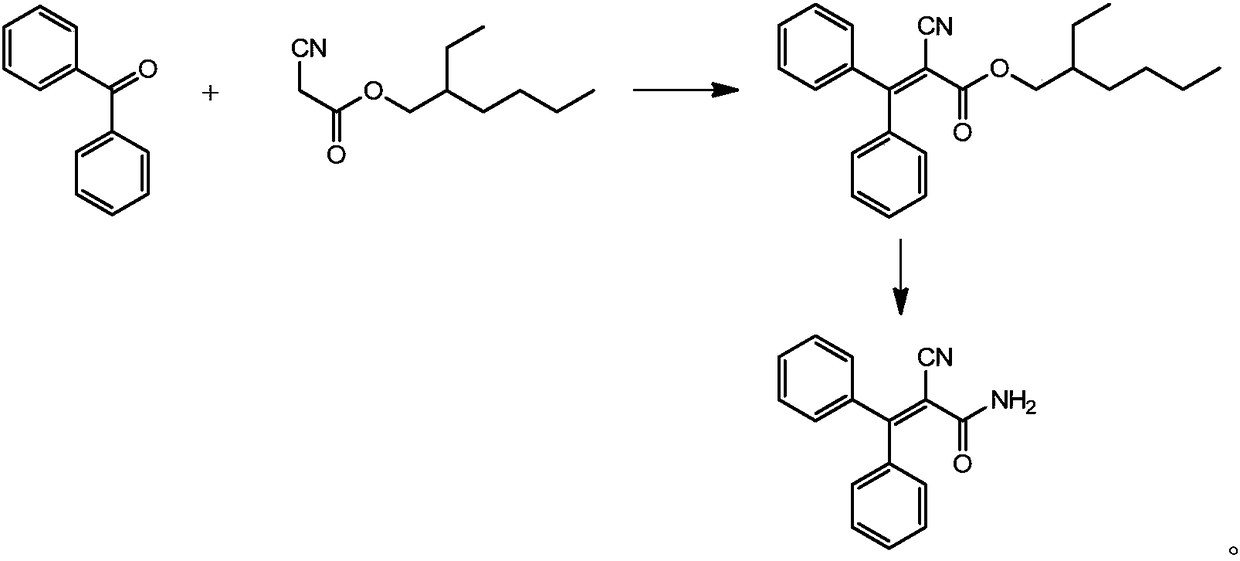

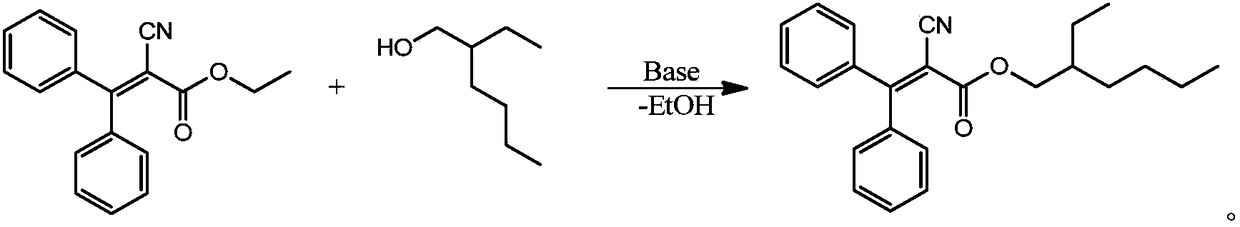

Image

Examples

preparation example Construction

[0047] A kind of preparation method of high-quality sunscreen agent octocrylene provided according to the present invention, wherein, described preparation method comprises the following steps:

[0048]Step 1): Recrystallize the raw material Etoridine, so that the content of harmful impurities benzophenone (BP) <500ppm, the content of 3,3-diphenylacrylonitrile (PCN) <50ppm, 2-cyano-3 , 3-diphenylacrylamide (Amide) content <50ppm, and etoridine (ETO) content ≥99.8%;

[0049] Wherein, the raw material Etocurene (ETO) crude product is obtained by the factory, and the impurity content is analyzed by gas chromatography (GC), which contains 1-3% of benzophenone, 0.1-0.3% of 3,3-diphenylacrylonitrile %, containing 95-97% of etoridine and 0.3-1% of 3,3-diphenylacrylamide.

[0050] It is preferable to use alcohol solvents, such as methanol, ethanol, isopropanol and sec-butanol, etc. when recrystallizing etoridine, preferably to use ethanol as the crystallization solvent.

[0051] Whe...

Embodiment 1

[0104] Relying on LEELEN recrystallization treatment:

[0105] Add 1470kg of Etocrine (ETO) crude product and 5880kg of 95% ethanol in the crystallization kettle, wherein, GC analysis contains BP2.48%, PCN 0.17%, ETO 96.47%, Amide 0.81% in the Etocrine crude product.

[0106] Start stirring, raise the temperature to 65°C, and cool down to 43°C for 2 hours after the materials are completely dissolved. After the heat preservation is over, continue to cool down to 8°C for 1 hour. Filtration obtained 1285kg of off-white ETO crystals, which contained BP 308ppm, PCN 46ppm, Amide<10ppm, ETO content was 99.9160%, and the yield was 87.41% according to GC analysis.

[0107] transesterification reaction:

[0108] In the transesterification kettle, add above-mentioned etoridine 1000kg and 3000kg isooctyl alcohol (EH) after the recrystallization. Start stirring, control the vacuum degree of the reaction system at 15-20mmHg, and slowly heat the material in the kettle to 82-85°C, and cont...

Embodiment 2

[0119] Compared with Example 1, the difference is that catalyst sodium carbonate is added at one time in the transesterification reaction.

[0120] After the transesterification reaction, 1197.8 kg of OCT crude product was obtained with a yield of 91.89%. GC analysis content obtained, EH7793.8ppm, BP 728.9ppm, PCN 969.5ppm, ETO 60.3ppm, Amide<10ppm, 2-imino-3,3-ethyl diphenylacrylate (ECDP) 1945.2ppm, and OCT content ( GC) 98.82%.

[0121] Thin film distillation treatment:

[0122] one stage thin film distillation

[0123] Distillation treatment parameter settings are the same as in Example 1. After one-stage distillation treatment, the OCT reboiler was obtained, and the content was analyzed by GC. The harmful impurities EH 20ppm, BP 18ppm, PCN<10ppm, ETO 50ppm, Amide<10ppm, ECDP 1950ppm, and the OCT content was 99.43%;

[0124] two-stage thin film distillation

[0125] The above-mentioned first-stage distillation product was distilled again, and the parameters were set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com