Preparation method of cement plate material with high surface compactness

A cement and board technology, which is applied in the field of preparation of high-density cement boards on the surface, can solve the problems of aging service life, insufficient surface hardness, water seepage of cement boards, etc., and achieve good scratch resistance and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

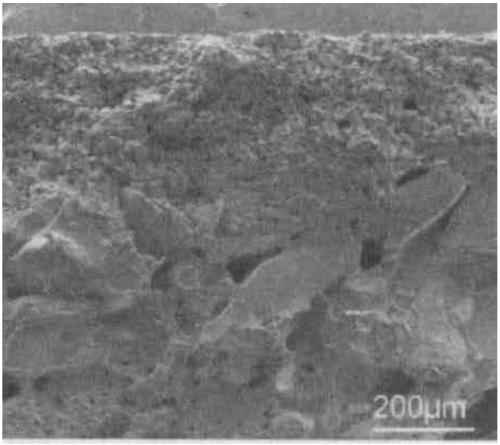

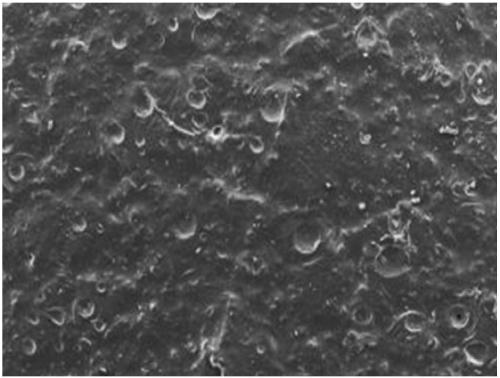

Image

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of surface high-density cement plate, and this preparation method comprises the following steps:

[0030] Step 1, preparation of glass powder filler:

[0031] Weigh each raw material according to the formula ratio, and the formula of glass powder filler is as follows in terms of mass percentage: 30-35% industrial grade boric acid, 10-15% spodumene powder, 10% feldspar powder, 20-30% Talc powder, 5-10% vanadium sulfide, 5% tin oxide and 10-15% calcium fluoride;

[0032] Put the weighed raw materials into a V-shaped mixer and mix them for 1-2 hours at 30 rpm;

[0033] Put the mixed raw materials into the crucible furnace, raise the temperature from room temperature to 1200°C at a rate of 3-6°C / min, keep it warm for 0.5-1 hour, and make glass liquid;

[0034] Pour the molten glass into water and cool to form broken glass;

[0035] Put the broken glass pieces into a roller crusher for crushing, the distance betw...

Embodiment 1

[0050] The present invention provides a kind of preparation method of surface high-density cement plate, and this preparation method comprises the following steps:

[0051] Step 1, preparation of glass powder filler:

[0052] Take each raw material by formula ratio, the formula of glass powder filler, by mass percent, is as follows: 35% technical grade boric acid, 10% spodumene powder, 10% feldspar powder, 20% talcum powder, 5% Vanadium sulfide, 5% tin oxide and 15% calcium fluoride;

[0053] Put the weighed raw materials into a V-shaped mixer and mix them for 2 hours at 30 rpm;

[0054] Put the mixed raw materials into a crucible furnace, raise the temperature from room temperature to 1200°C at a rate of 4°C / min, and keep it warm for 1 hour to make molten glass;

[0055] Pour the molten glass into water and cool to form broken glass;

[0056] Put the broken glass pieces into a roller crusher for crushing, the distance between the two rollers is 0.2 mm, and dry the crushed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com