Whole wheat flour product and preparation method thereof

A technology for products and wheat noodles, which is applied in the field of whole wheat flour products and its preparation, and can solve problems such as lack of elasticity, rough internal structure, and reduced extensibility of whole wheat flour dough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

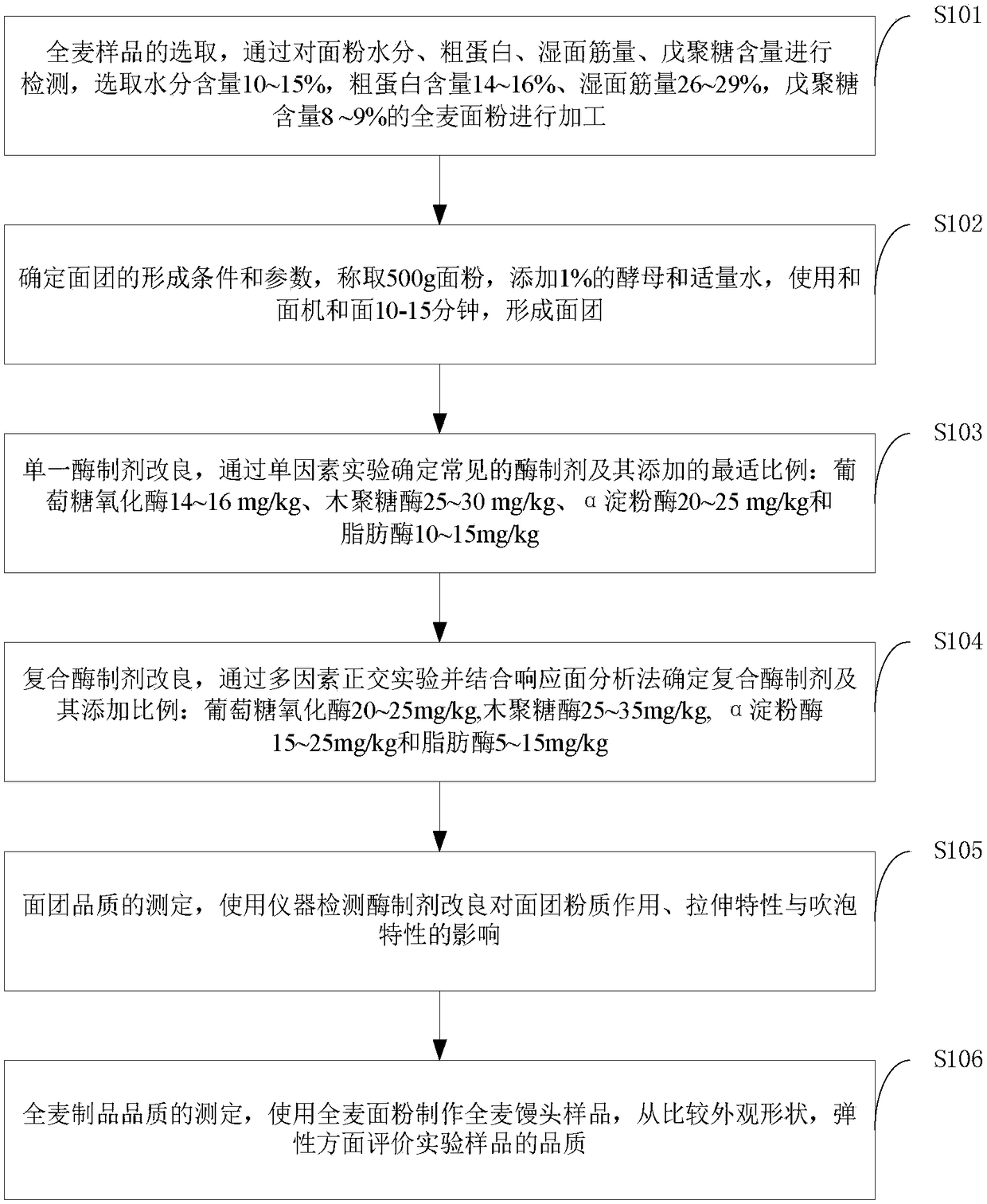

[0030] like figure 1 As shown, the preparation method of the whole wheat flour product that the embodiment of the present invention provides comprises the following steps:

[0031] S101, the selection of whole wheat samples, through the detection of flour moisture, crude protein, wet gluten content, and pentosan content, select a moisture content of 10-15%, a crude protein content of 14-16%, and a wet gluten content of 26-29% , whole wheat flour with pentosan content of 8-9% is processed;

[0032] S102, determine the formation conditions and parameters of the dough, weigh 500g of flour, add 1% yeast and an appropriate amount of water, and use a dough mixer to knead the dough for 10-15 minutes to form a dough;

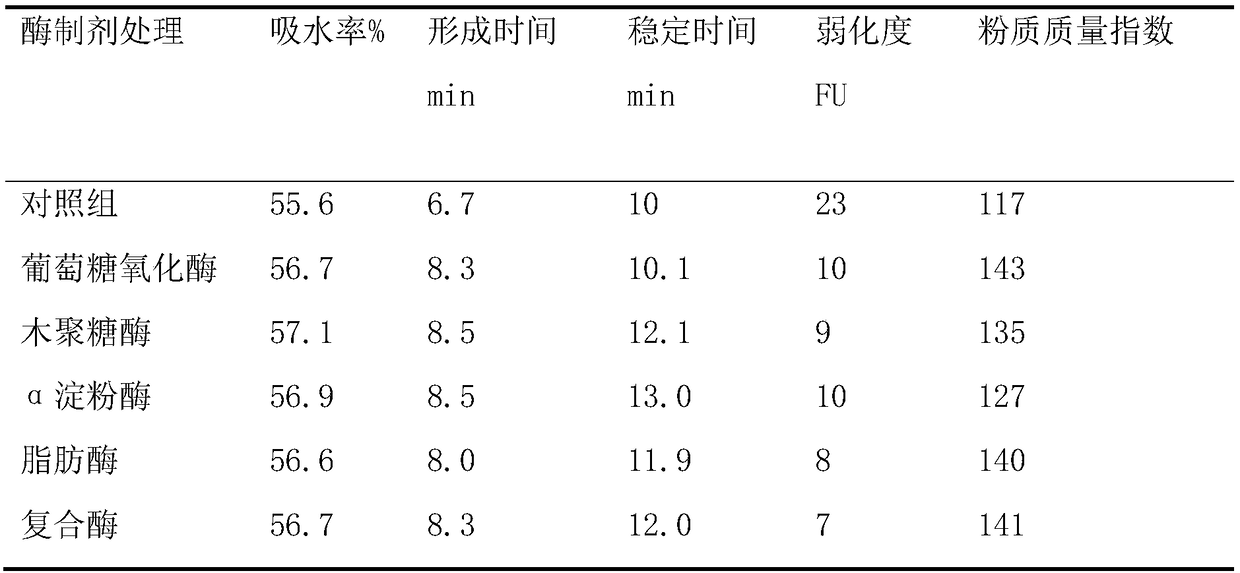

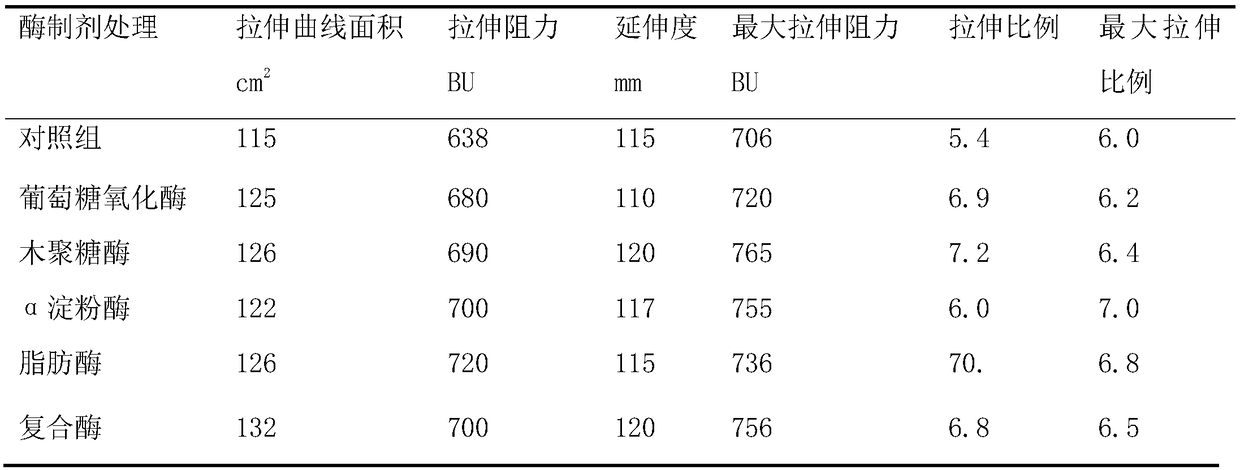

[0033] S103, improvement of single enzyme preparation, determine the common enzyme preparation and its optimal ratio by single factor experiment: glucose oxidase 14-16mg / kg, xylanase 25-30mg / kg, α-amylase 20-25mg / kg kg and lipase 10-15mg / kg;

[0034] S104, Improveme...

Embodiment 1

[0041]The processing process of conventional whole-wheat flour products is as follows: choose whole-wheat flour with a moisture content of 10-15%, a crude protein content of 14-16%, a wet gluten content of 26-29%, and a pentosan content of 8-9%. 500g of the above-mentioned flour, add 1% yeast and appropriate amount of water, and use a dough mixer to knead the dough for 10-15 minutes to form a dough; place the dough in a 28°C, 80-90RH fermentation box for proofing for 60-90 minutes. The dough reaches About 1.5 times the original volume, the internal structure of the dough is honeycomb. Divide the dough into 10 parts of equal size, roll them into round shapes by hand, and then proof them again in a fermentation box at 28°C and 880-90RH for 20 minutes. After the last 25 minutes, turn off the heat, take it out after 5 minutes of stuffiness, and let it stand at room temperature for 1 hour.

Embodiment 2

[0043] Glucose oxidase-improved whole-wheat flour products are processed as follows: choose whole-wheat flour with a moisture content of 10-15%, a crude protein content of 14-16%, a wet gluten content of 26-29%, and a pentosan content of 8-9%. 14mg / kg of glucose oxidase is improved, weigh 500g of the flour, add 1% yeast and appropriate amount of water, use a dough mixer to knead the dough for 10-15 minutes to form a dough; place the dough at 28°C, 80-90RH for fermentation Proof in the box for 60-90 minutes. The dough should reach about 1.5 times the original volume, and the internal structure of the dough should be honeycomb. Divide the dough into 10 parts of equal size, roll them into round shapes by hand, and then proof them again in a fermentation box at 28°C, 880-90RH for 20 minutes. After the last 25 minutes, turn off the heat, take it out after 5 minutes of stuffiness, and let it stand at room temperature for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com