Preparation method of a new load-bearing composite material

A technology of composite materials and mixtures, applied in the field of load-bearing materials, can solve problems such as unsuitable for static-sensitive equipment handling materials, difficult to meet mechanical properties, processing and use hazards, etc., to achieve good rigidity, wide operating temperature range, and light engineering design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

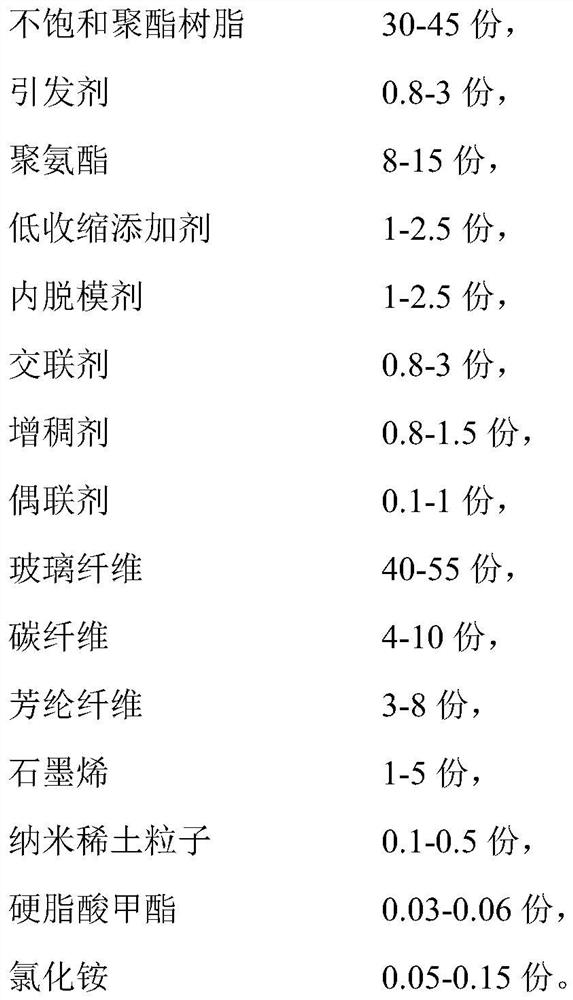

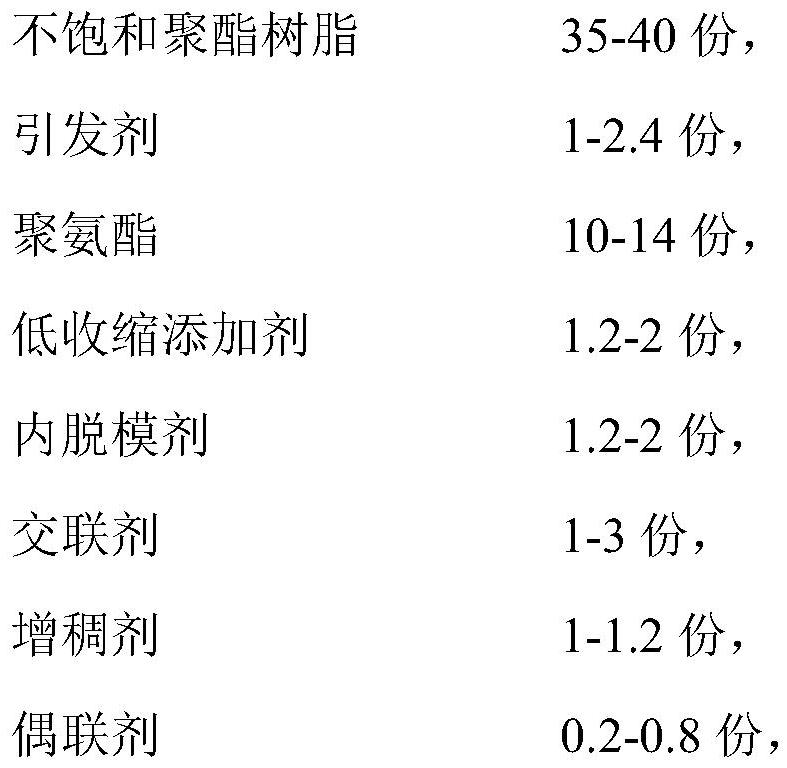

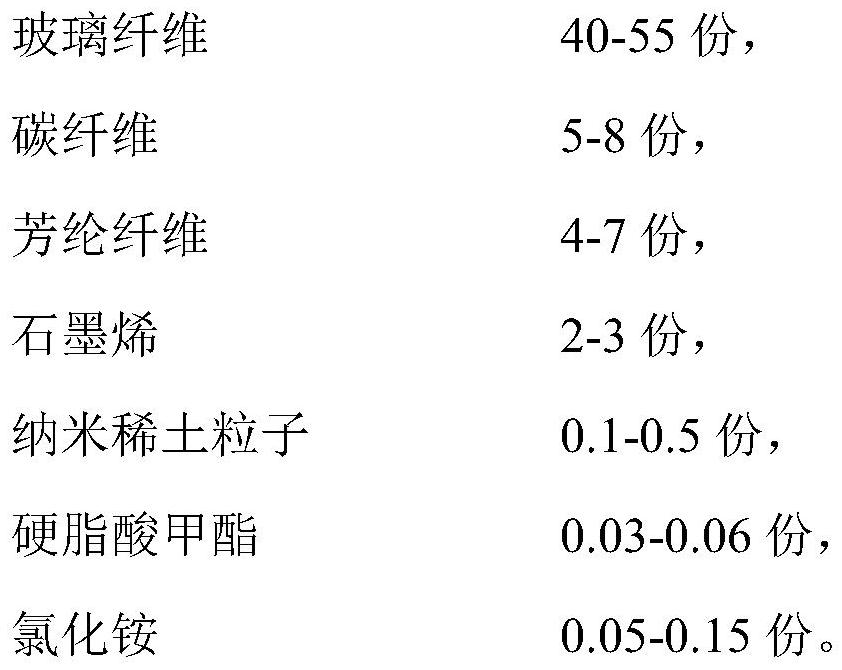

[0034] A novel load-bearing composite material, the preparation method of which comprises the following steps:

[0035] (1) Add 0.1 part of nano-rare earth particles (composed of nano-yttrium oxide, nano-praseodymium oxide and nano-scandium oxide with a ratio of 1:2:2) to 1 part of graphene, mix well, and heat up to within 1 minute. 80-90°C, keep warm for 5-10 minutes, then cool down to 40-50°C within 10 seconds, then add 30 parts of unsaturated polyester resin, 0.8 parts of peroxy ketal, 8 parts of polyurethane, 1 part of polyacetic acid-benzene Ethylene, 1 part of internal mold release agent, 0.8 part of diacetone acrylamide, 0.8 part of thickener, 0.1 part of coupling agent, 0.03 part of methyl stearate, 0.05 part of ammonium chloride, 40 parts of glass fiber, after mixing evenly , to get mixture A;

[0036] (2) Lay half of the mixture A in the molding mold, and then evenly arrange 4 parts of carbon fiber and 3 parts of aramid fiber on the half of the molding mold with hal...

Embodiment 2

[0039] A novel load-bearing composite material, the preparation method of which comprises the following steps:

[0040] (1) Add 0.5 parts of nano-rare earth particles (composed of nano-yttrium oxide, nano-praseodymium oxide and nano-scandium oxide with a ratio of 1:2:2) to 5 parts of graphene, mix well, and heat up to within 1 minute. 80-90°C, keep warm for 5-10 minutes, then cool down to 40-50°C within 10 seconds, then add 45 parts of unsaturated polyester resin, 3 parts of initiator, 15 parts of polyurethane, 2.5 parts of low shrinkage additive, 2.5 parts Internal mold release agent, 3 parts of crosslinking agent, 1.5 parts of thickener, 1 part of coupling agent, 0.06 part of methyl stearate, 0.15 part of ammonium chloride, 55 parts of glass fiber, after mixing uniformly, mixture A is obtained;

[0041] (2) Lay half of the mixture A in the molding mold, and then evenly arrange 10 parts of carbon fiber and 8 parts of aramid fiber on the quarter of the molding mold with half o...

Embodiment 3

[0044] A novel load-bearing composite material, the preparation method of which comprises the following steps:

[0045] (1) Add 0.3 parts of nano-rare earth particles (composed of nano-yttrium oxide, nano-praseodymium oxide and nano-scandium oxide with a ratio of 1:2:2) to 1 part of graphene, mix well, and heat up to within 1 minute. 80-90°C, keep warm for 5-10 minutes, then cool down to 40-50°C within 10 seconds, then add 38 parts of unsaturated polyester resin, 2 parts of peroxy ketal, 12 parts of polyurethane, 1.5 parts of polyacetic acid-benzene Ethylene, 1.5 parts of internal mold release agent, 2 parts of diacetone acrylamide, 1.2 parts of thickener, 0.5 parts of coupling agent, 0.05 parts of methyl stearate, 0.1 parts of ammonium chloride, 48 parts of glass fiber, after mixing evenly , to get mixture A;

[0046](2) Lay half of the mixture A in the molding mold, and then evenly arrange 7 parts of carbon fiber and 6 parts of aramid fiber on the three equal parts of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com