A kind of preparation method with high modulus high elastic polyurethane fiber

A polyurethane fiber, high elasticity technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, single-component synthetic polymer rayon, etc., can solve the problems of elastic recovery loss, elastic recovery rate deviation, low modulus, etc., to achieve elasticity The effect of high retention rate, good rebound and high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

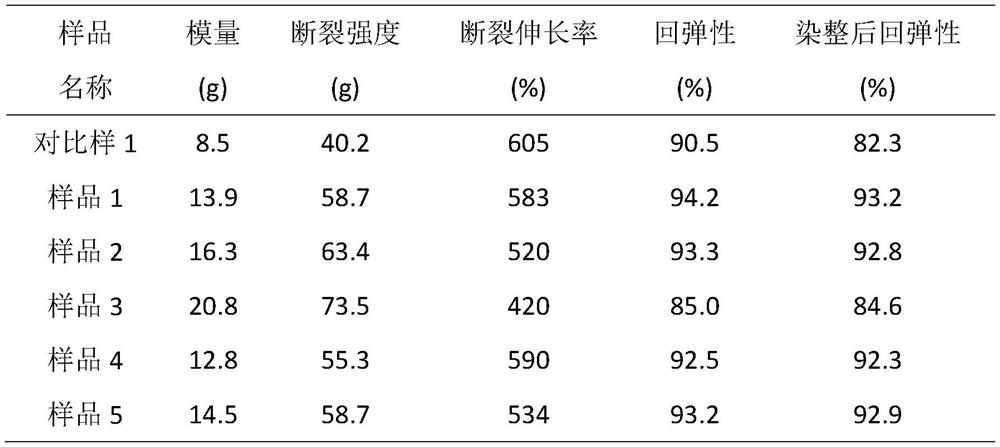

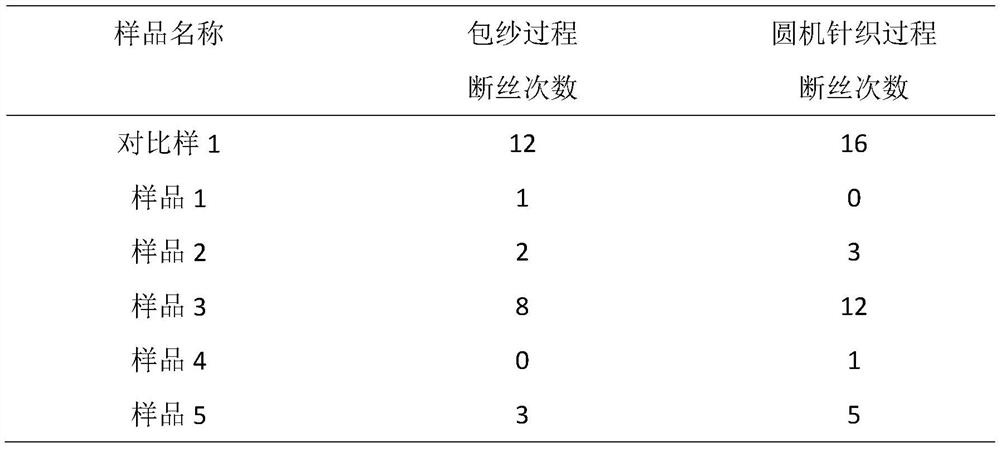

Examples

preparation example Construction

[0024] (1). Preparation of acrylonitrile polymer solution. First place the acrylonitrile polymer in a 60-100 degree oven for dehydration and drying for 12-24 hours. Then put the acrylonitrile polymer into a mixing tank equipped with a polar organic solvent, stir and dissolve at a constant temperature of 40-80 degrees for 5-24 hours. Then, the solution was filtered using a filter to obtain an acrylonitrile-based polymer solution.

[0025] (2). Preparation of mixed spinning dope. Mix the polyurethane solution with the acrylonitrile polymer solution, add lubricant, antioxidant, UV-resistant auxiliary agent, dyeing auxiliary agent, etc. for aging, and stir at a constant temperature of 40-60 degrees for 24-48 hours to obtain the mixed spinning Silk stock solution.

[0026] (3). Dry spinning process of mixed dope. The mixed spinning stock solution is transported to the gear pump, and then through the fine holes of the spinneret to form a thin stream of the stock solution; the th...

Embodiment 1

[0034] Select 1.2Kg of polyacrylonitrile powder with a molecular weight of about 80,000 and place it in an oven at 80 degrees to dry for 24 hours. Then polyacrylonitrile was put into 6.0Kg dimethylacetamide, the temperature was raised to 60°C, and the mixture was stirred and mixed at high speed for 10 hours. Filter the solution with a 2000-3000 mesh filter to obtain a polyacrylonitrile solution with a viscosity of 3000 poise. Select 31.0 kg of a polyurethane solution with a mass fraction of 35% and a viscosity of 4000 poise, mix it with the polyacrylonitrile solution, add lubricants, antioxidants, UV-resistant auxiliaries, and dyeing auxiliaries at the same time, and stir at a constant temperature of 50 degrees for 24 hours , to obtain the mixed spinning dope. Then the mixed spinning stock solution is transported to the gear pump, and the fine stream of the stock solution is formed through the fine holes of the spinneret; the fine stream of the stock solution evaporates the s...

Embodiment 2

[0036] The method adopted in embodiment 2 is the same as that in embodiment 1, except that the consumption of polyacrylonitrile is changed to 2.7 kg, and the spandex thus obtained is designated as sample 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com