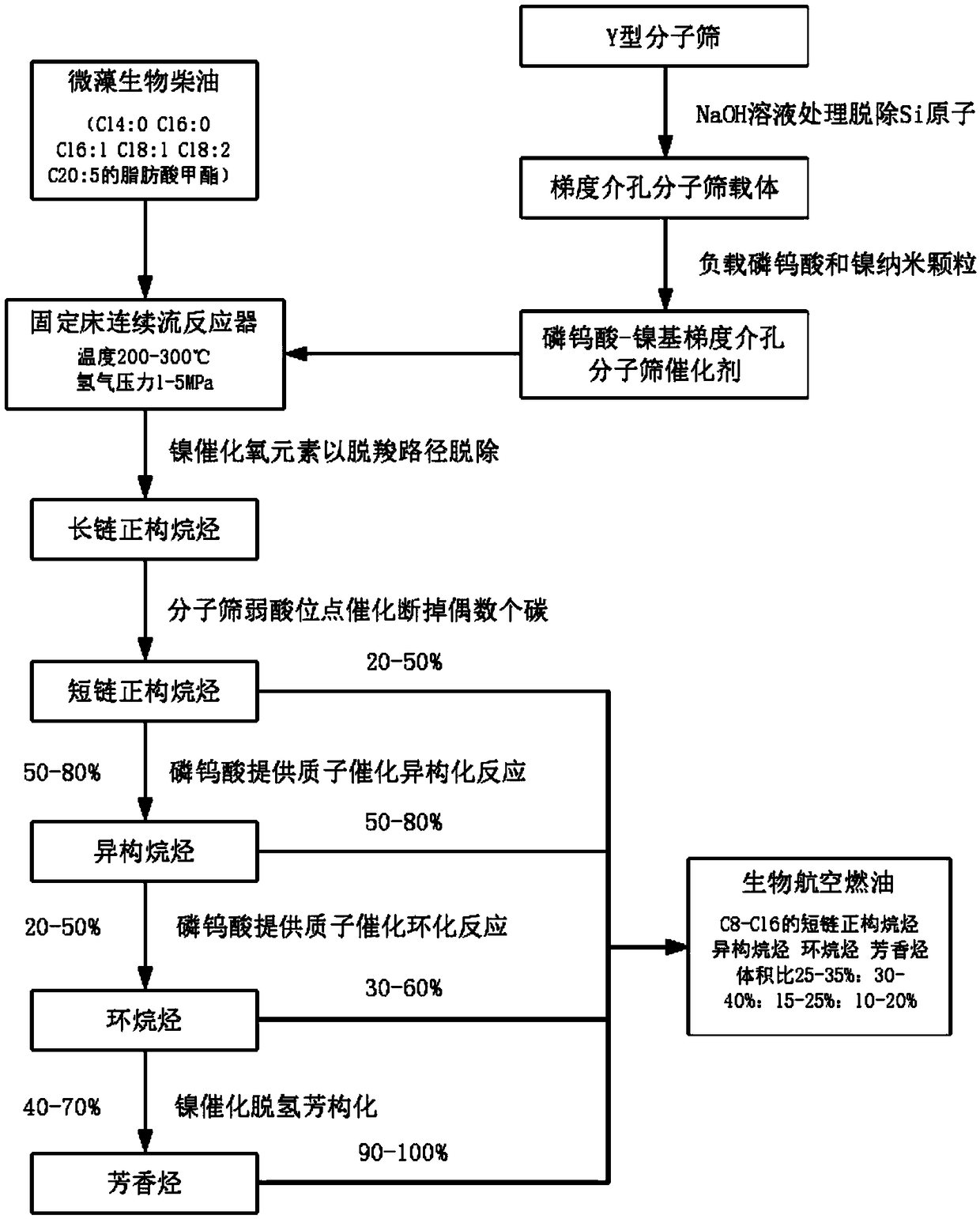

Method for preparing aviation oil through catalyzing algae oil by virtue of phosphotungstic acid-loaded nickel base molecular sieve

A molecular sieve, phosphotungstic acid technology, applied in molecular sieve catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of affecting pore structure and acid distribution, affecting the reaction pathway of fatty acid methyl ester deoxygenation and bond breaking, etc. Enhanced reactivity, product selectivity, and improved contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 5 g of Y-type molecular sieve raw materials into 50 mL of NaOH solution with a concentration of 0.05 M, and stir for 0.25 h with a magnetic stirrer to make the OH - Ions and molecular sieve framework unit SiO 4 Si atoms in the center combine to form free Si(OH) 4 , by continuously removing Si atoms, a gradient distribution mesopore of 2-10 nm is formed on the molecular sieve framework. Then add hydrochloric acid to neutralize to pH = 7, filter the liquid by suction filtration, wash once with deionized water, add 50mL of NH with a concentration of 0.1M 4 The Cl solution was ion-exchanged for 0.25 h, and the liquid was filtered out by suction filtration, and then washed once with deionized water to obtain a gradient mesoporous molecular sieve carrier.

[0034] Take 4.3g of gradient mesoporous molecular sieve carrier, weigh 0.2g of phosphotungstic acid H 3 [P(W 3 o 10 ) 4 ] and 2.48g nickel nitrate hexahydrate Ni(NO 3 ) 2 ·6H 2 O, mixed and added to 20 mL of d...

Embodiment 2

[0037] Add 100g of Y-type molecular sieve raw material into 1000mL NaOH solution with a concentration of 1M, and stir for 8h with a magnetic stirrer to make the OH - Ions and molecular sieve framework unit SiO 4 Si atoms in the center combine to form free Si(OH) 4 , by continuously removing Si atoms, a gradient distribution mesopore of 2-10 nm is formed on the molecular sieve framework. Then add hydrochloric acid to neutralize to pH = 7, filter the liquid by suction filtration, wash with deionized water 5 times, add 1000mL of 2M NH 4 The Cl solution was ion-exchanged for 2 hours, the liquid was filtered out by suction filtration, and then washed with deionized water for 5 times to obtain a gradient mesoporous molecular sieve carrier.

[0038] Take 86g of gradient mesoporous molecular sieve carrier, weigh 4g of phosphotungstic acid H 3 [P(W 3 o 10 ) 4 ] and 49.54g nickel nitrate hexahydrate Ni (NO 3 ) 2 ·6H 2 O, mixed and added to 400 mL of deionized water. Stir with ...

Embodiment 3

[0041] Add 20 g of Y-type molecular sieve raw materials into 200 mL of NaOH solution with a concentration of 0.2 M, and stir for 2 h with a magnetic stirrer to make the OH - Ions and molecular sieve framework unit SiO 4 Si atoms in the center combine to form free Si(OH) 4 , by continuously removing Si atoms, a gradient distribution mesopore of 2-10 nm is formed on the molecular sieve framework. Then add hydrochloric acid to neutralize to pH = 7, filter the liquid by suction filtration, wash twice with deionized water, add 200mL of 1M NH 4 The Cl solution was ion-exchanged for 1 h, and the liquid was filtered out by suction filtration, and then washed twice with deionized water to obtain a gradient mesoporous molecular sieve carrier.

[0042] Take 17.2g of gradient mesoporous molecular sieve carrier, weigh 0.8g of phosphotungstic acid H 3 [P(W 3 o 10 ) 4 ] and 9.908g nickel nitrate hexahydrate Ni (NO 3 ) 2 ·6H 2 O, mixed and added to 200 mL of deionized water. Stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com