Hollow microsphere-containing waterborne polyurethane matting resin and preparation method thereof

A technology of water-based polyurethane and matting resin, which is applied in the preparation of microspheres, polyurea/polyurethane coatings, microcapsule preparations, etc. It can solve the problems of multi-seed appearance of the film, uneven dispersion of matting agents, and easy condensation of components. Achieve the effects of avoiding poor compatibility of physical mixing, environmentally friendly and simple preparation method, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material used in this embodiment and weight description are as follows:

[0030] 20g of toluene diisocyanate, 480g of acetone-water mixture (mix acetone and water uniformly at a mass ratio of 6:4 to obtain acetone-water mixture), 8g of diethylenetriamine, 15.5g of isophorone diisocyanate, polyethylene glycol Butylene glycol ester diol 25g (molecular weight 2000), stannous octoate 0.05g, dimethylol butyric acid 1.4g, 1,4-butanediol 1.5g, triethylamine 1g, deionized water 100g.

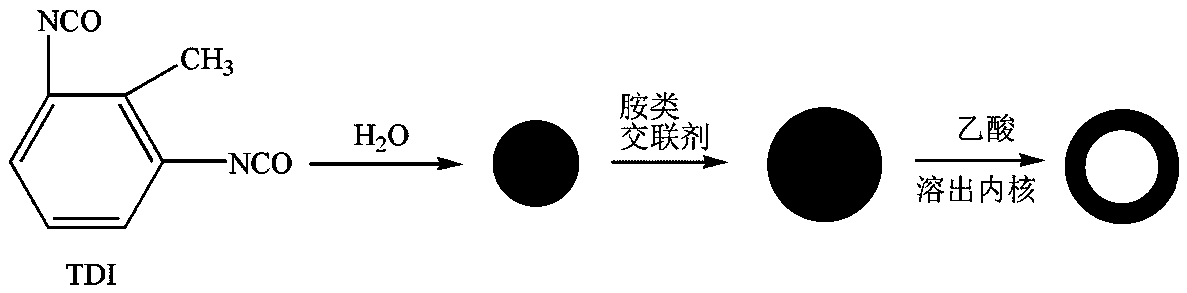

[0031] see figure 1 , the preparation operation steps of adding the water-based polyurethane matting resin of hollow microspheres are as follows:

[0032] (1) Slowly add 20g of toluene diisocyanate into 480g of acetone-water mixture, keep the rotation speed at 30rpm at 30°C, stir slowly for 3h, add 8g of diethylenetriamine cross-linking agent and drip it within 3h to obtain poly Urea core-shell microsphere dispersion;

[0033] (2) Ultrasound the dispersion of polyurea core-shell microspher...

Embodiment 2

[0037] Raw material used in this embodiment and weight description are as follows:

[0038] Toluene diisocyanate 20g, acetone-water mixture 480g (mix acetone and water uniformly to obtain acetone-water mixture at a mass ratio of 7: 3), triethylenetetramine 8.5g, isophorone diisocyanate 16g, polycarbonate Diol 25g (molecular weight 2000), stannous octoate 0.05g, dimethylol butyric acid 1.4g, 1,4-butanediol 1.5g, triethylamine 1g, deionized water 100g.

[0039] see figure 1 , the preparation operation steps of adding the water-based polyurethane matting resin of hollow microspheres are as follows:

[0040] (1) Slowly add 20g of toluene diisocyanate into 480g of acetone-water mixture, keep the rotation speed at 30rpm at 30°C, slowly stir for 3h, then add 8.5g of diethylenetriamine cross-linking agent and drop it in 3h to prepare Obtain polyurea core-shell microsphere dispersion;

[0041] (2) Ultrasound the dispersion of polyurea core-shell microspheres for 30 minutes to disperse...

Embodiment 3

[0045] Raw material used in this embodiment and weight description are as follows:

[0046] Toluene diisocyanate 20g, acetone water mixture 280g, the mass ratio of the two is 8:2, diethylenetriamine 8g, toluene diisocyanate 14g, polybutylene adipate diol 25g (molecular weight 2000), dihydroxy 1.4g methyl propionic acid, 2g 1,4-butanediol, 1g triethylamine, 120g deionized water.

[0047] see figure 1 , the preparation operation steps of adding the water-based polyurethane matting resin of hollow microspheres are as follows:

[0048] (1) Slowly add 20g of toluene diisocyanate into 480g of acetone-water mixture, keep the rotation speed at 30rpm at 30°C, slowly stir for 3h, then add 8g of diethylenetriamine cross-linking agent and drop it in 3h to obtain Polyurea core-shell microsphere dispersion;

[0049] (2) Ultrasound the dispersion of polyurea core-shell microspheres for 30 minutes to disperse evenly, centrifuge at a high speed of 10,000 rpm for 10 minutes, wash the polyure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com