Low-modulus high-elongation and high-thixotropy ageing-resistant sealant and preparation method thereof

A technology with high elongation and thixotropy, applied in the field of sealants, can solve the problems of high thixotropy, aging resistance, high cost, poor concrete adhesion, etc., and achieve non-deteriorating durability, excellent high deformation performance, and superior durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

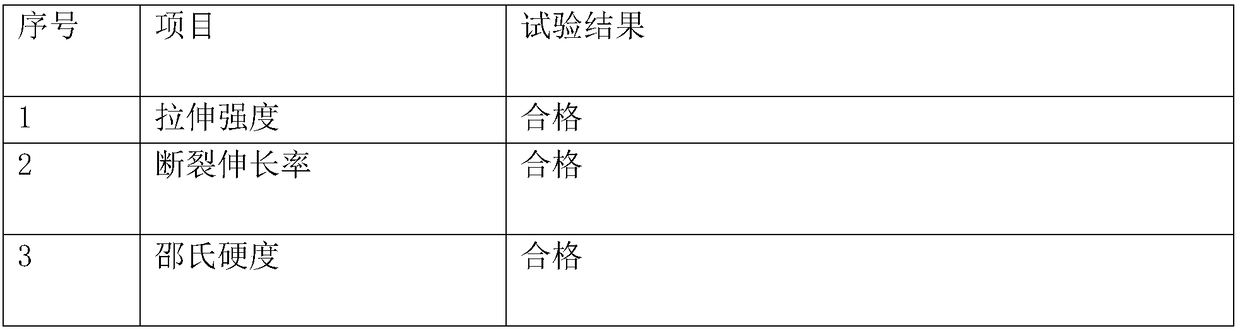

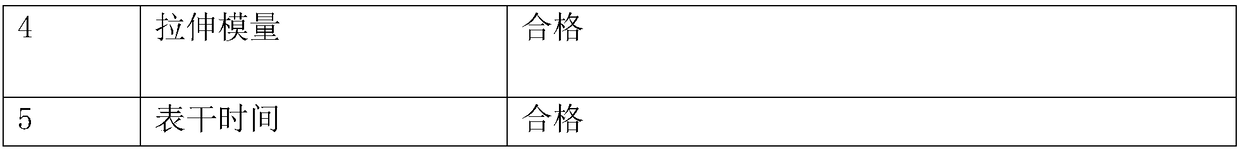

Examples

preparation example Construction

[0022] The invention provides a sealant with low modulus, high elongation, high thixotropy and aging resistance and a preparation method thereof, comprising silicone rubber, filler, reinforcing agent, crosslinking agent, catalyst, plasticizer, chain extender, Vulcanization accelerators, pigments, thixotropic agents, tackifiers, stabilizers, heat-resistant agents and antifungal agents, the mass fraction of silicone rubber is 15-20, the mass fraction of fillers is 10-13, and the mass fraction of reinforcing agents The mass fraction is 7-8, the mass fraction of crosslinking agent is 5-7, the mass fraction of catalyst is 6-8, the mass fraction of plasticizer is 5-7, the mass fraction of chain extender is 2-3, vulcanization The mass fraction of the accelerator is 1-3, the mass fraction of the pigment is 1-2, the mass fraction of the thixotropic agent is 3-6, the mass fraction of the tackifier is 4-5, and the mass fraction of the stabilizer is 3-4 , the mass fraction of the heat-res...

Embodiment 1

[0031] Recipe and its proportions:

[0032] The mass fraction of silicone rubber is 15, the mass fraction of filler is 10, the mass fraction of reinforcing agent is 7, the mass fraction of crosslinking agent is 5, the mass fraction of catalyst is 6, and the mass fraction of plasticizer is 5 , the mass fraction of the chain extender is 2, the mass fraction of the vulcanization accelerator is 1, the mass fraction of the pigment is 1, the mass fraction of the thixotropic agent is 3, the mass fraction of the tackifier is 4, and the mass fraction of the stabilizer is 3. The mass fraction of the heat-resistant agent is 5 and the mass fraction of the fungicide is 4; its preparation method:

[0033] Step 1: Put the silicone rubber, filler, reinforcing agent and cross-linking agent into the double planetary stirring tank according to the measurement, stir for 1 hour and evacuate;

[0034] Step 2: Add metered catalyst, plasticizer, chain extender, vulcanization accelerator, pigment, th...

Embodiment 2

[0040] Recipe and its proportions:

[0041] The mass fraction of silicone rubber is 18, the mass fraction of filler is 11, the mass fraction of reinforcing agent is 7.5, the mass fraction of crosslinking agent is 6, the mass fraction of catalyst is 7, and the mass fraction of plasticizer is 6 , the mass fraction of the chain extender is 2.5, the mass fraction of the vulcanization accelerator is 2, the mass fraction of the pigment is 1.5, the mass fraction of the thixotropic agent is 4, the mass fraction of the tackifier is 4.5, and the mass fraction of the stabilizer is 3.5, the mass fraction of the heat-resistant agent is 6 and the mass fraction of the fungicide is 5; its preparation method:

[0042] Step 1: Put the silicone rubber, filler, reinforcing agent and cross-linking agent into the double planetary stirring tank according to the measurement, stir for 1 hour and evacuate;

[0043] Step 2: Add metered catalyst, plasticizer, chain extender, vulcanization accelerator, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com