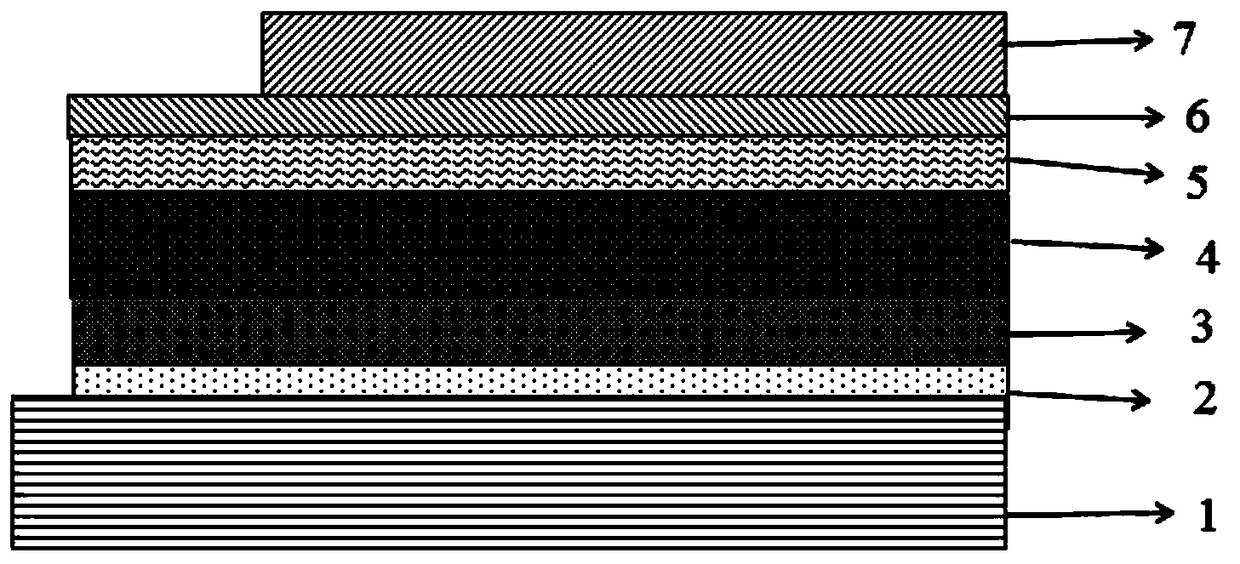

Method for regulating and controlling appearance of lead-free perovskite solar cell and solar cell device prepared by the same

A solar cell and lead-free perovskite technology, applied in the field of solar cells, can solve the problems of limitation and high extinction coefficient, and achieve the effect of reducing density defects, less pinhole structure, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one: in tin iodide (SnI 2 ) and formamidine iodine (FAI) to add 0wt% citric acid (CA) additive to control the morphology of lead-free perovskite solar cell devices.

[0024] Step 1: The glass substrate engraved with the ITO electrode is ultrasonically cleaned in deionized water, acetone, and ethanol for 14 minutes each, and then thoroughly cleaned and placed in an ozone plasma processor to clean the surface for 5 minutes;

[0025] Step 2: Preparation of the hole transport layer: Spin-coat the PEDOT:PSS solution on the ITO glass at a speed of 4000 rpm, and then anneal at 130° C. for 20 min.

[0026] Step 3: the preparation of precursor solution: tin iodide (SnI 2 ) and formamidine iodine (FAI) were dissolved in a mixed solvent of dimethylamide (DMF) and dimethyl sulfoxide (DMSO) at a volume ratio of 8:2, and the final molar concentration of the precursor solution was 1.0mol / L , and stirred at room temperature for 2h;

[0027] Step 4: Spin-coat the lead-free...

Embodiment 2

[0030] Embodiment two: in tin iodide (SnI 2 ) and formamidine iodine (FAI) to add 5wt% citric acid (CA) additives to control the morphology of lead-free perovskite solar cell devices.

[0031] The difference from the preparation steps disclosed in Example 1 lies in Step 3, and all other steps and methods are exactly the same as in Example 1.

[0032] Step 3 of this embodiment: tin iodide (SnI) with a molar ratio of 1:1 2 ) and formamidine iodine (FAI) and 5wt% citric acid (CA) additives were dissolved in a mixed solvent of dimethylamide (DMF) and dimethyl sulfoxide (DMSO) at a volume ratio of 8:2, the precursor The final molar concentration of the solution was 1.0mol / L, and stirred at room temperature for 2h.

Embodiment 3

[0033] Embodiment three: in tin iodide (SnI 2 ) and formamidine iodine (FAI) to add 10wt% citric acid (CA) additives to control the morphology of lead-free perovskite solar cell devices.

[0034] The difference from the preparation steps in Example 1 is Step 3, and all other steps and methods are exactly the same as in Example 1.

[0035] Step 3 of this embodiment: tin iodide (SnI) with a molar ratio of 1:1 2) and formamidine iodine (FAI) and 10wt% citric acid (CA) additives were dissolved in a mixed solvent of dimethylamide (DMF) and dimethyl sulfoxide (DMSO) at a volume ratio of 8:2, the precursor The final molarity of the solution was 1.0mol / L, and stirred at room temperature for 2h.

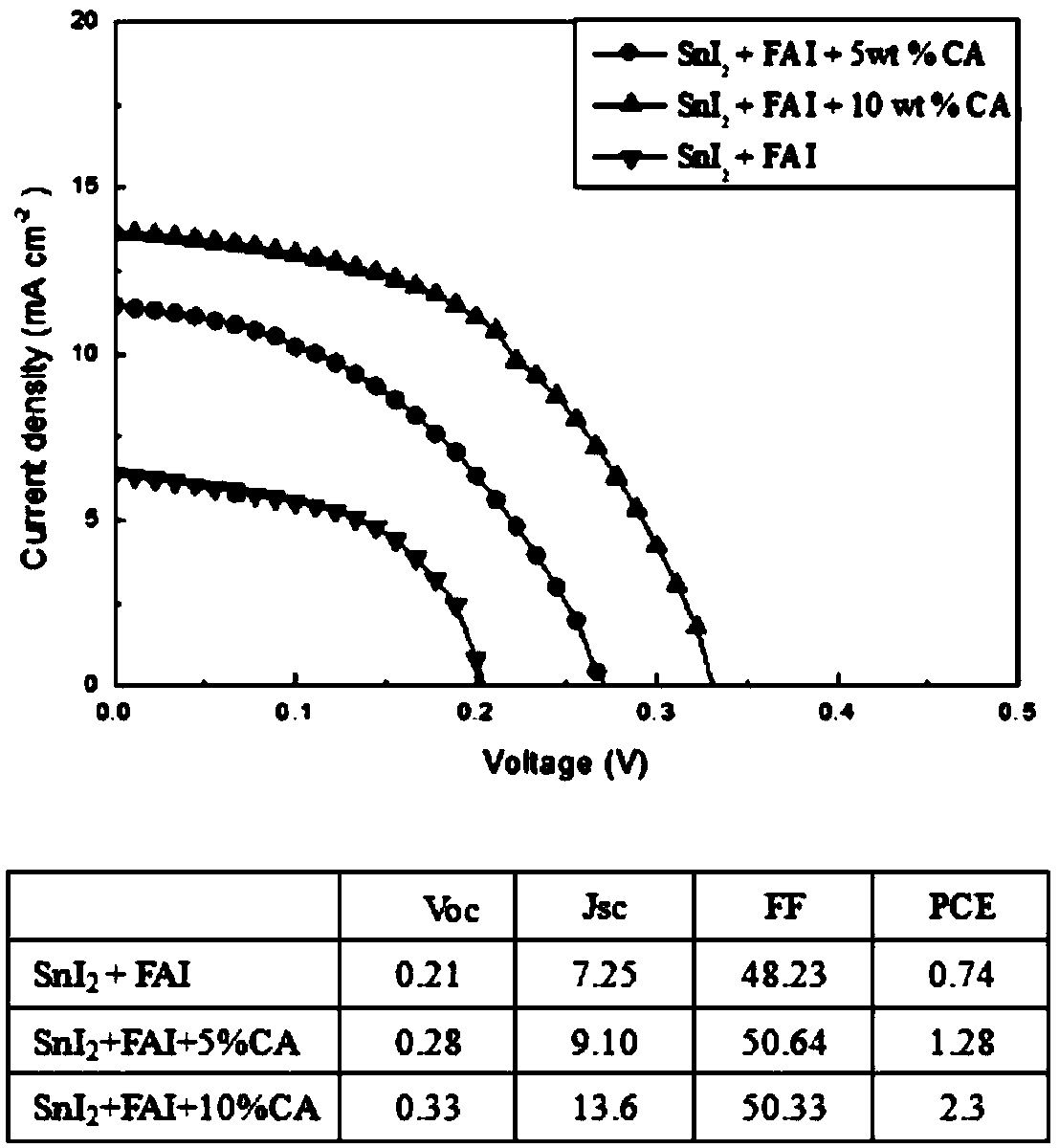

[0036] Embodiment one, the solar cell device prepared in embodiment two and embodiment three carry out the test of photoelectric efficiency, compare the photoelectric conversion efficiency of three kinds of perovskite solar cells, the result is as follows figure 2 shown, from figure 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com