Ozone oxidation catalyst based on active carbon carrier and preparation method thereof

A technology of ozone oxidation and activated carbon, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Reduced ozone dosage, reduced operating costs, and efficient removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

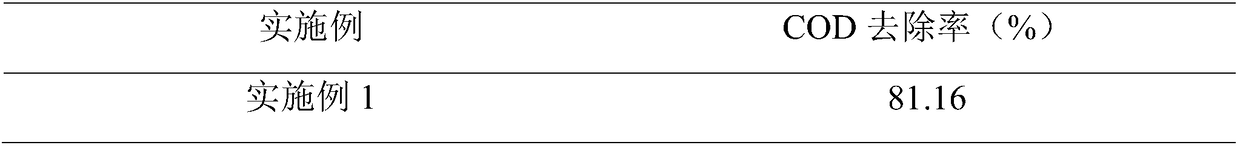

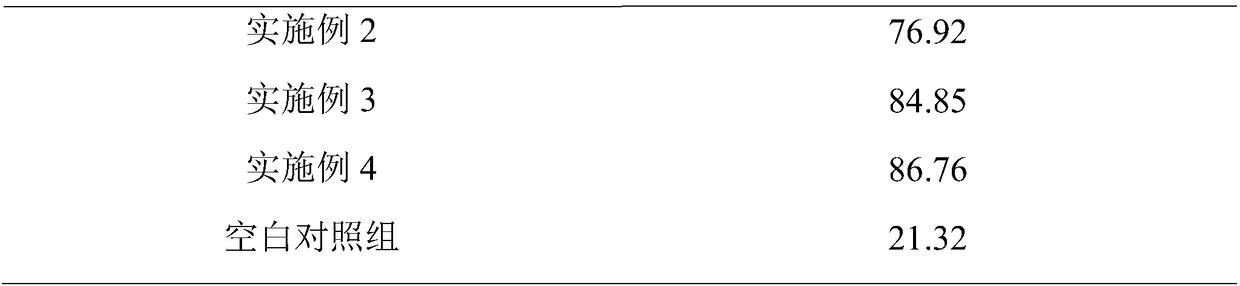

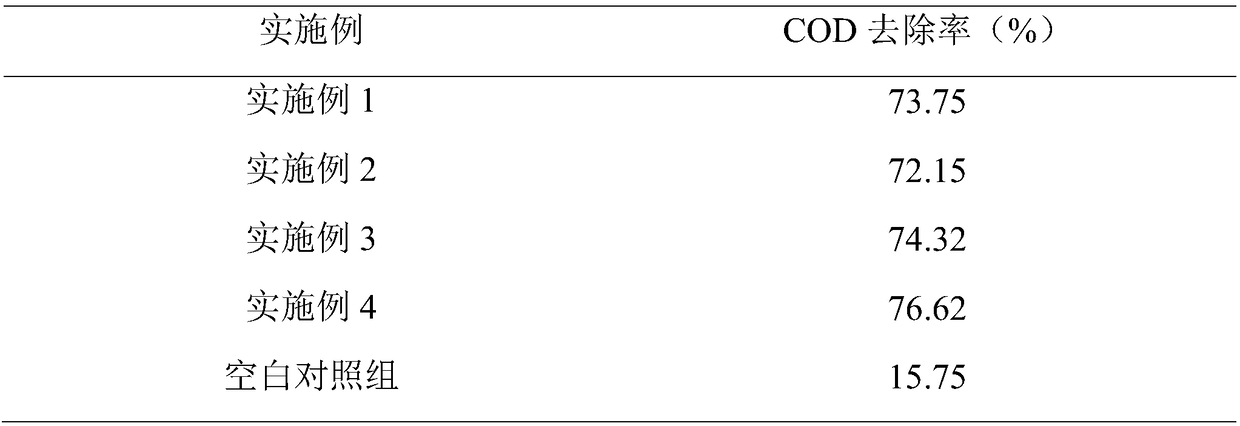

Examples

preparation example Construction

[0022] And, the embodiment of the present invention also provides a kind of preparation method of the ozone oxidation catalyst based on active carbon carrier, comprises the following steps:

[0023] S01. Provide an activated carbon carrier, dry it, and test the water absorption of the dried activated carbon carrier;

[0024] S02. The activated carbon carrier is placed in a container, and the precursor solution of the metal oxide is added by an equal-volume impregnation method, and the metal oxide precursor is adsorbed and then dried;

[0025] S03. Put the activated carbon carrier adsorbed with the metal oxide precursor into a heating device, and under the protection of an inert atmosphere, heat-preserve and calcinate at 300-650°C for 3-10 hours, and obtain an ozone oxidation catalyst based on the activated carbon carrier after aging treatment.

[0026] Specifically, in the above step S01, preferably, the activated carbon carrier has a diameter of 0.5-3mm and a specific surface...

Embodiment 1

[0039] The diameter is 0.88-2.36mm, the specific surface area (BET)>500m 2 / g of activated carbon carrier, put it in a drying oven and dry it at 120°C. Put the weighed activated carbon carrier into the ferric nitrate solution for immersion treatment, put the activated carbon carrier adsorbed on the ferric nitrate into a drying oven and dry at 100°C for 12h. The dried samples were placed in a resistance furnace and raised to 400°C for calcination, kept for 4 hours, and aged for 24 hours to obtain Fe 2 o 3 Ozone oxidation catalyst with a loading of 3%.

Embodiment 2

[0041] The diameter is 0.88-2.36mm, BET>500m 2 / g of activated carbon carrier, put it in a drying oven and dry it at 100°C. Put the weighed activated carbon carrier into the manganese nitrate solution for impregnation treatment, and stir for 2 hours. The activated carbon carrier adsorbed manganese nitrate was put into a drying oven and dried at 120°C for 12h. The dried samples were placed in a resistance furnace and raised to 500°C for calcination, kept for 6 hours, and aged for 24 hours to obtain MnO 2 Ozone oxidation catalyst with a loading of 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com