Sulfur-tolerant shift catalyst and preparation method thereof

A sulfur-resistant conversion and catalyst technology, which is applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of low activity and non-existence of waste agents, and achieve the goal of not easy to lose and long service life Long-lasting, low-cost production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

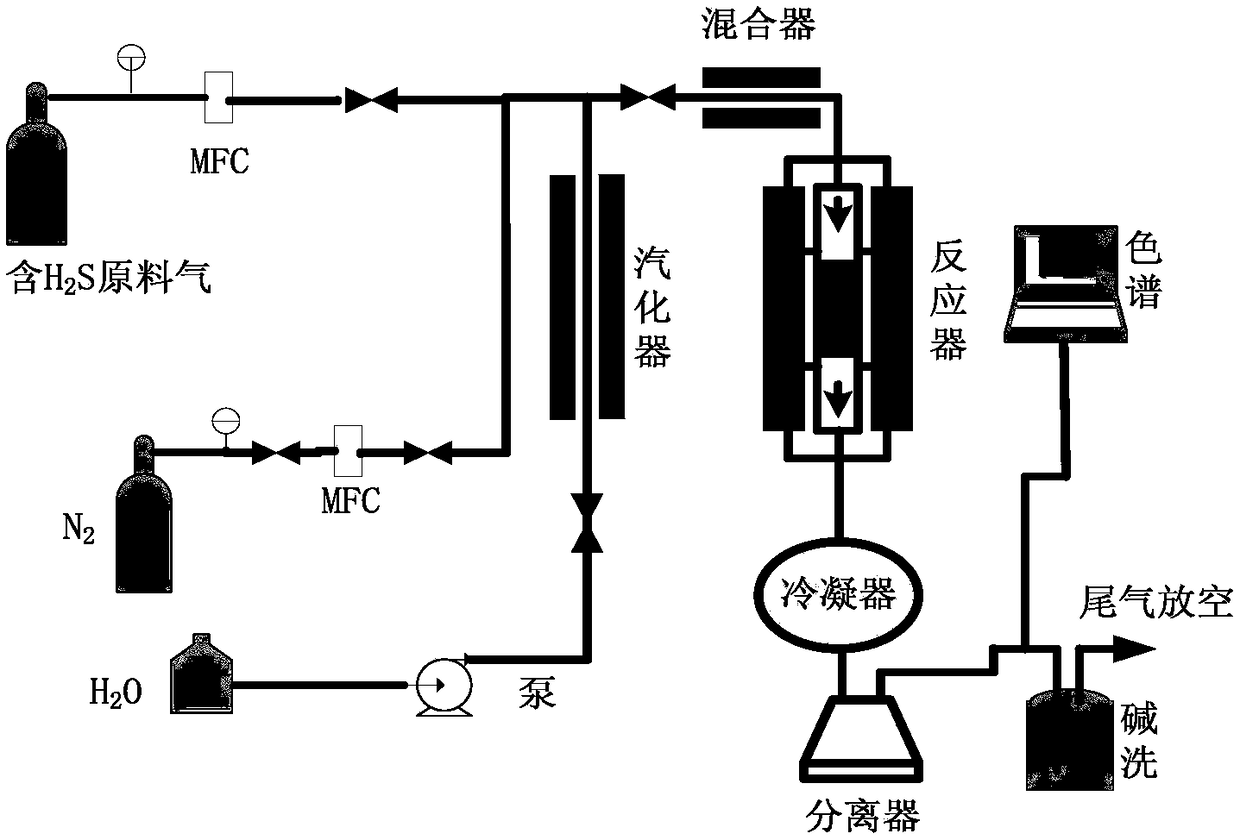

Method used

Image

Examples

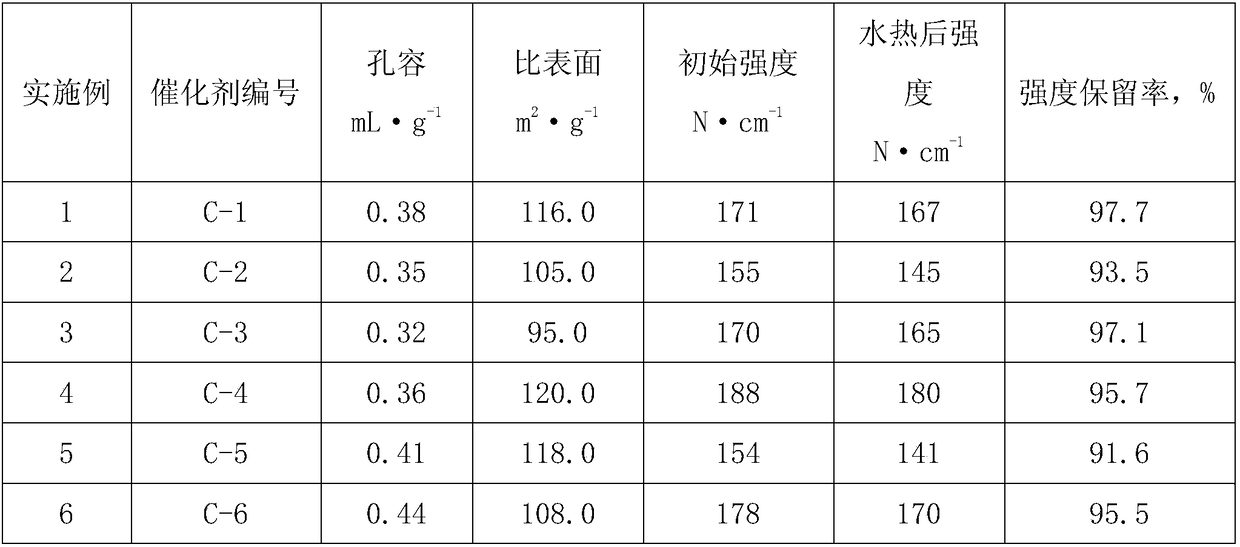

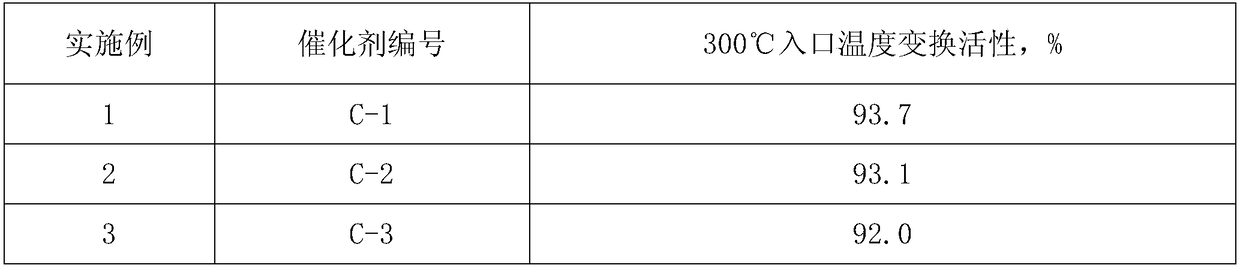

Embodiment 1

[0056] First, the waste FCC agent is roasted at 650°C for 5 hours, and then crushed through a 200-mesh sieve.

[0057] Dissolve 8.6g of ammonium molybdate in 40.0ml of deionized water to obtain molybdenum-containing solution A; dissolve 11.7g of cobalt nitrate in 30.0ml of deionized water; add 3.0g of citric acid and 1.0g of oxalic acid into the above solution and stir to dissolve , to obtain solution B containing cobalt.

[0058] Weigh 80.0g of the treated FCC waste agent, 8.6g of pseudoboehmite, 2.0g of magnesium oxide, 2.9g of metatitanic acid, and 3.0g of scallop powder, mix them evenly, add solution A, and knead evenly; then add solution B, Knead, shape, dry naturally, bake at 530°C for 3h, and then cool down to room temperature naturally. That is, the finished sulfur-tolerant shift catalyst C-1 was obtained. Its strength and strength stability are shown in Table 1.

Embodiment 2

[0060] First, the waste FCC agent is roasted at 800°C for 2 hours, and then crushed through a 180-mesh sieve.

[0061] Dissolve 9.8g of ammonium molybdate with 40.0ml of deionized water to obtain molybdenum-containing solution A; dissolve 7.8g of cobalt nitrate with 35.0ml of deionized water; then add 2.0g of sucrose to the above solution and stir to dissolve to obtain Cobalt solution B.

[0062] Weigh 70.0g of processed FCC waste agent, 10.0g of alumina, 4.0g of magnesia, 8.6g of metatitanic acid, 2.0g of starch and mix evenly, add solution A, knead evenly; then add solution B, knead, shape, Dry in the air, bake at 550°C for 2h, and then cool down to room temperature naturally. That is, the finished sulfur-tolerant shift catalyst C-2 was obtained. Its strength and strength stability are shown in Table 1.

Embodiment 3

[0064] First, the waste FCC agent is roasted at 550°C for 10 hours, and then crushed through a 220-mesh sieve.

[0065] Dissolve 8.0g of ammonium molybdate with 40.0ml of deionized water to obtain molybdenum-containing solution A; dissolve 13.3g of cobalt acetate with 35.0ml of deionized water; then add 5.0g of citric acid to the above solution, stir and dissolve to obtain Solution B containing cobalt.

[0066] Weigh 65.0g of the processed FCC waste agent, 20.0g of pseudo-boehmite, 8.0g of magnesium oxide, 2.0g of titanium oxide, and 4.0g of Tianqing powder, mix evenly, add solution A, and knead evenly; then add solution B, knead , Molded, dried naturally, baked at 400°C for 3h, and then cooled down to room temperature naturally. That is, the finished sulfur-tolerant shift catalyst C-3 was obtained. Its strength and strength stability are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com