Treatment process and system for carbide slag

A treatment process and technology of carbide slag, applied in the field of carbide slag treatment process and system, can solve the problems of affecting output, affecting the use of drying furnace, and poor drying effect of carbide slag materials, so as to improve production efficiency and output, and eliminate sticking Block, easy to calcine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

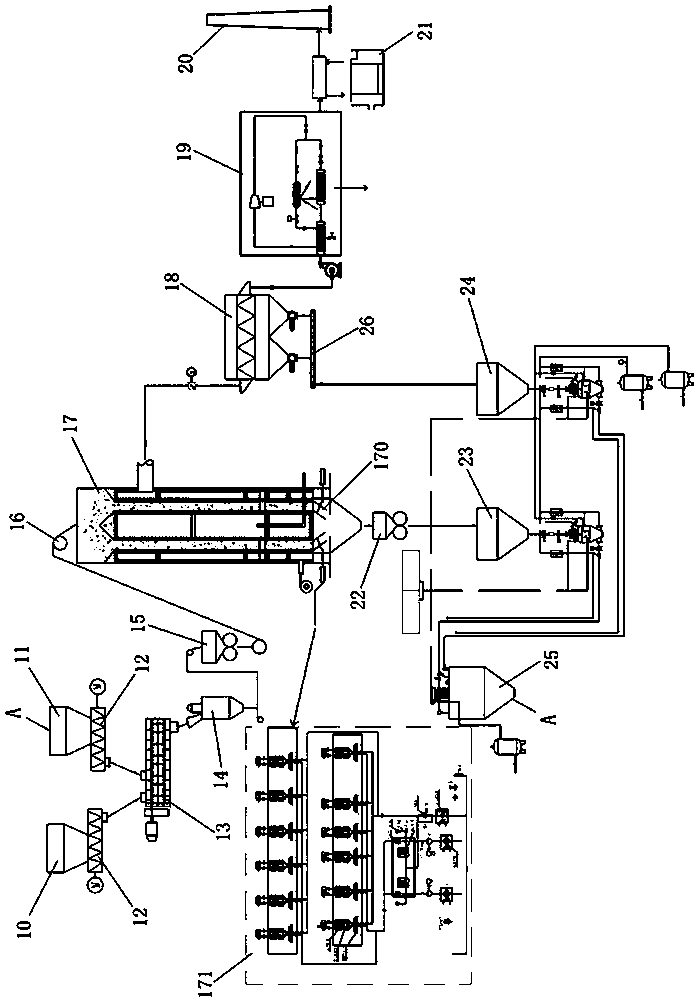

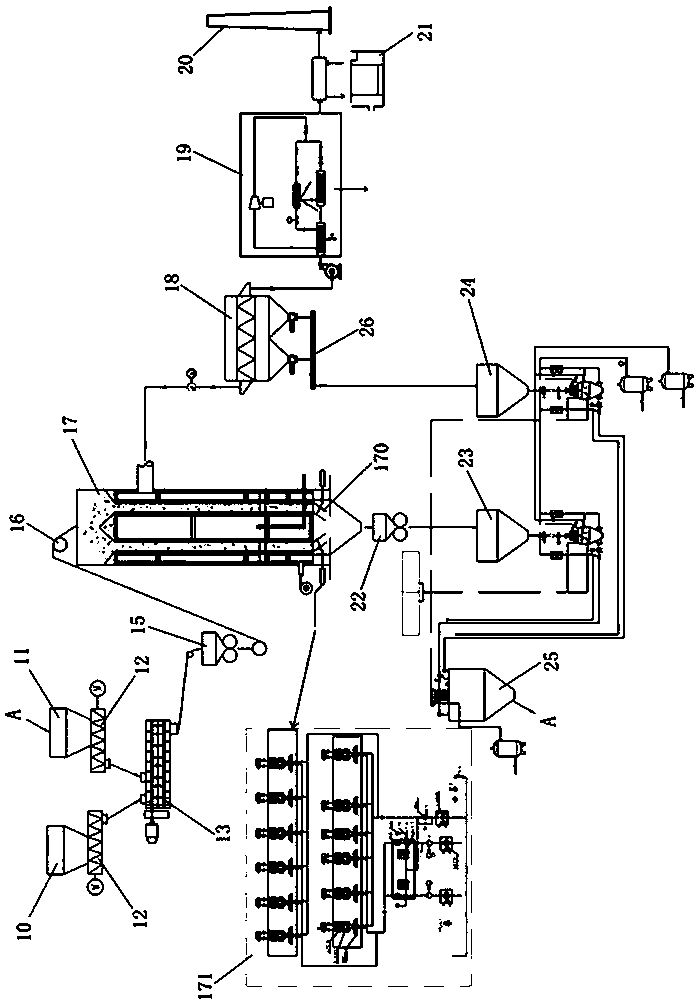

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Specific embodiment one of the calcium carbide slag processing system of the present invention, as figure 1 As shown, the calcium carbide slag silo 10 and the dry powder silo 11 are included, and the carbide slag silo 10 and the dry powder silo 11 transport the internal materials to the mixer 13 through the screw feeder 12 respectively, Carbide slag with a water content not less than 35% delivered from the calcium carbide slag silo 10 and dry powder delivered from the dry powder silo can be mixed and dispersed by the mixing and dispersing machine 13, so as to perform preliminary drying of the calcium carbide slag containing water .

[0031]The system also includes an agglomerate breaker 14 communicated with the discharge port of the mixer 13. When the dry powder and calcium carbide slag with more water are mixed and dispersed by the mixer 13, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com