A kind of reactive and thermosensitive microgel modified water-based UV curing ink and preparation method thereof

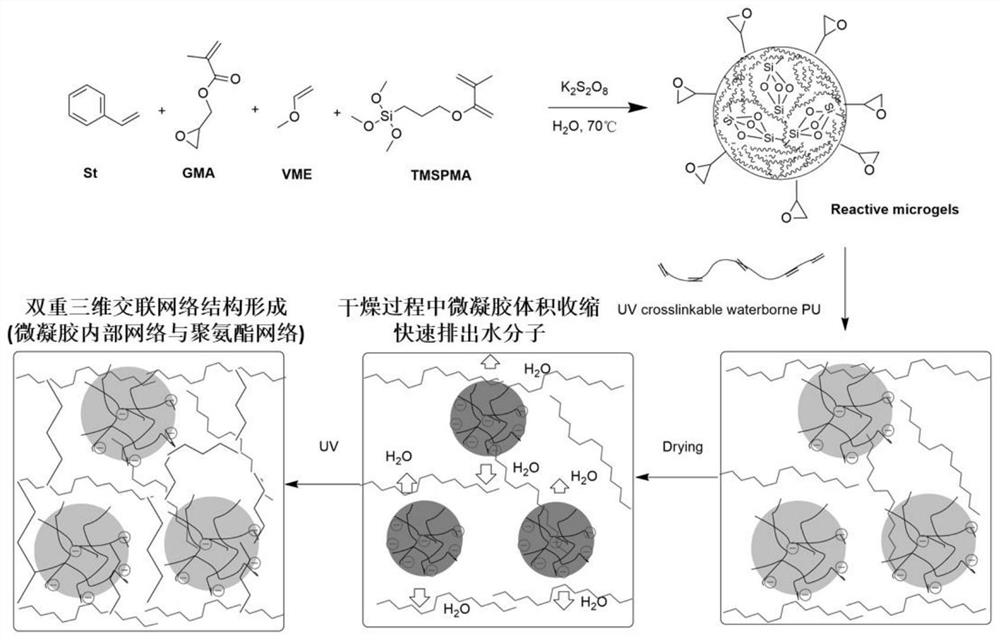

A microgel and reactive technology, applied in the field of water-based UV curable ink and its preparation, can solve the problems of affecting the production efficiency of printed products, restricting the development of water-based ink, slow drying speed of water-based ink, etc., and achieves improvement in properties such as ink film hardness , Improve the ink solid content, the effect of fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of Ink polyurethane binder (1) UV curable waterborne

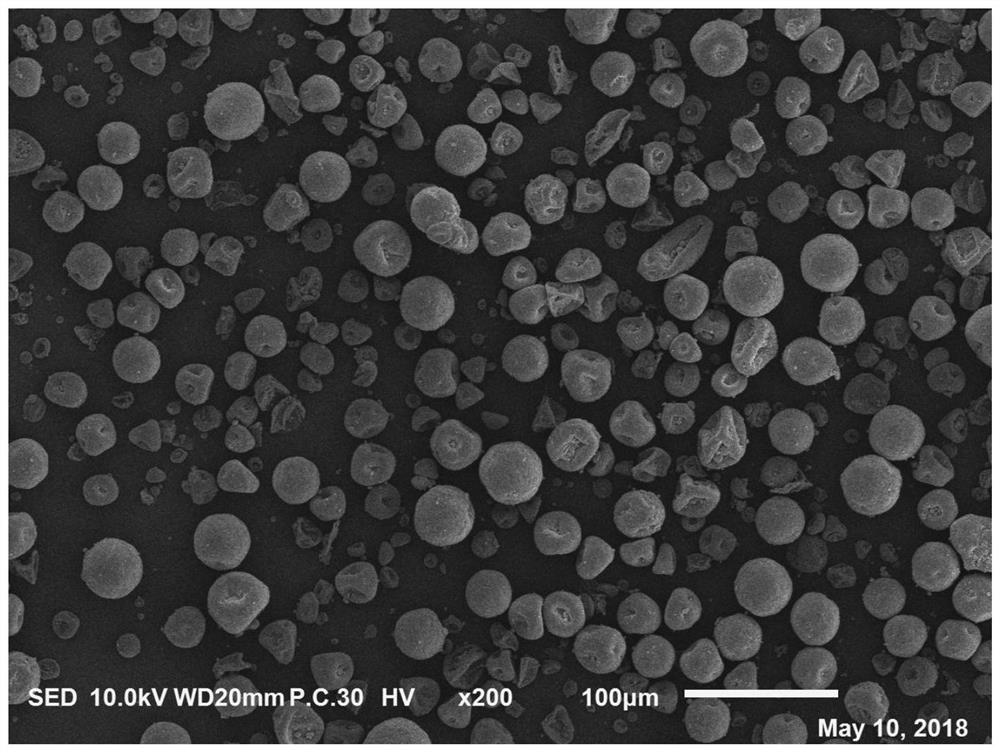

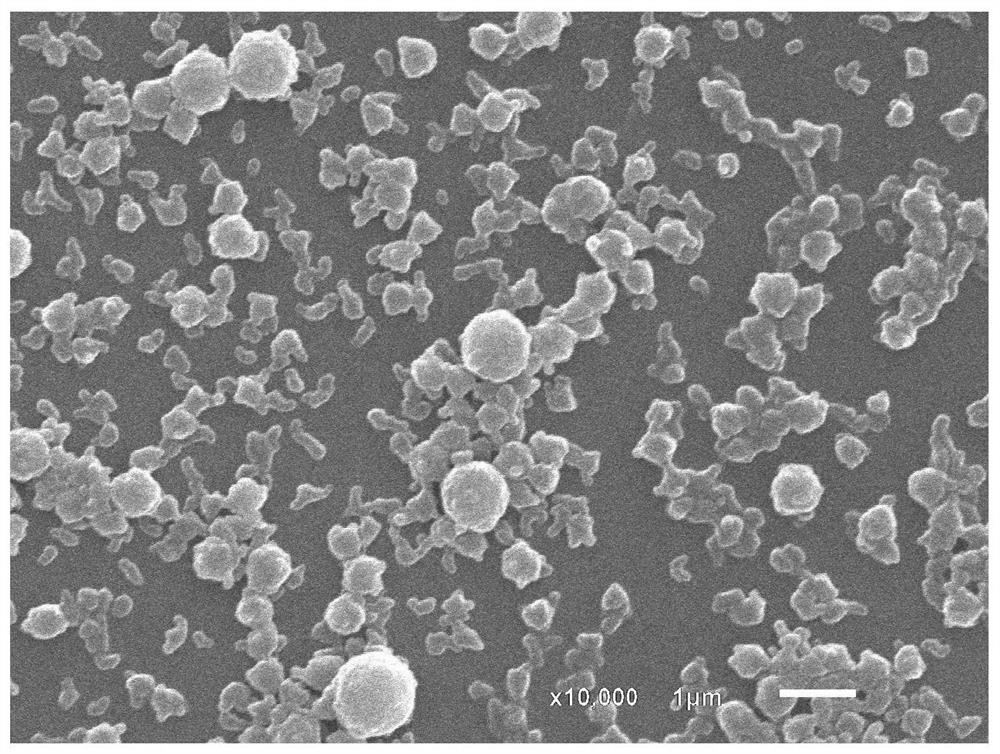

[0037]In the three-necular flask (35 parts) of hydroxymethylpropionic acid (35 parts), isocyanate (40), isocyanate (40), isocyanate (40), isocyanate (40), isocyanate (40) Series), dibutyl tin (0.5 parts) heated to 45 ° C and nitrogen gas protection reaction 2 h, and the value of the isocyanate in the reactant was measured until the value of the isocyanate was no longer changed, and polyethylene glycol was added. One part of the solution was raised to 65 ° C to continue to react for 6 h, and after the reaction was complete, acrylic-β-hydroxypropionyl (5 parts) was added. Cooling to normal temperature, neutralization of triethanolamine and salt; figure 2 The scanning electron microscopy of the polyurethane linker (drying) obtained by the aqueous UV cured ink obtained in Example 1, which can be seen from the figure that the polyurethane linker is present in the form of a particulate form.

[0038] (2) Preparati...

Embodiment 2

[0045] (1) Preparation of polyurethane linker with water-based UV cured ink

[0046] In the three-neck flask (36 parts) of hydroxymethylpropionic acid (36 parts), isocyanate (42), isocyanate (42), isocyanate (42) Series), dibutyl tin (0.5 parts) heating to 50 ° C and nitrogen protection reaction for 2 h, and the value of the isocyanate in the reactant is no longer changed, and polyethylene glycol is added to the reactant. 2 parts) The solution was warmed to 66 ° C for 6 h, and after the reaction was complete, acrylic-β-hydroxypropproppropprodu (7 parts) was added. Cooling to normal temperature, neutralization of triethanolamine and salt;

[0047] (2) Preparation of microgel particles having reactivity, temperature responsiveness and internal crosslinked network structure

[0048] In the three-neck flask equipped with a stirrer, a condenser and a controlled device, deionized water is added, and methyl methyl methacrylate (11 parts), T monomermethyl ether (72 parts) is added. E mono...

Embodiment 3

[0054] (1) Preparation of polyurethane linker with water-based UV cured ink

[0055] In the three-neck flask (37 parts) of hydroxymethylpropion (37 parts), isocyanate (45), isocyanate (45), isocyanate (45) Series), Dibuttin (0.5 parts) heated to 55 ° C and nitrogen gas protection reaction for 2 h, and the value of the isocyanate in the reactant was measured until the value of the nitric acid was not changed, and polyethylene glycol was added. Thirty) The solution was warmed to 67 ° C to continue to react for 6 h, and after the reaction was complete, acrylic-β-hydroxypropproppropprodu (8 parts) was added. Cooling to normal temperature, neutralization of triethanolamine and salt;

[0056] (2) Preparation of microgel particles having reactivity, temperature responsiveness and internal crosslinked network structure

[0057] In a three-neck flask equipped with a stirrer, a condenser and a controlled device, deionized water is added, and hydroxyethyl methacrylate (12 parts), T monomer N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com