Process for preparing derived fuel RDF-5 through coupling of township domestic garbage and biomass

A technology of RDF-5 and domestic waste, which is applied in the field of preparing derivative fuel RDF-5, which can solve the problems of toxic slag and dust, waste of land resources, and no treatment methods, and achieve less environmental pollution, reduce equipment corrosion, and reduce corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

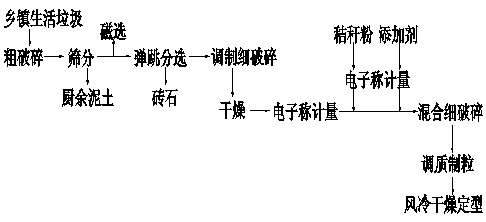

[0015] Such as figure 1 As shown, the process of coupling township domestic waste and biomass to prepare derived fuel RDF-5 in this embodiment includes the following steps: 1) Coarse crushing: Separately crush township domestic waste and biomass such as straw through a coarse crusher; 2) Screening: Separating the broken township domestic waste through drum sieves to separate kitchen waste and soil; 3) Magnetic separation: Adsorb and separate iron impurities in township domestic waste through a magnet separator; 4) Bounce separation: pass The bouncing sorter separates solid impurities with large specific gravity such as bricks and stones; 5) Fine crushing: the township domestic waste is further crushed by the fine crusher; 6) Drying: the remaining combustibles of township domestic waste are dried to the water content by the hot air dryer 20-30%; 7) Mixing: Measured by electronic scales, according to the mass percentage, the proportion of dried township domestic waste combustibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com