Strain and construction method thereof, and application thereof in fermentative production of high temperature resistant xanthan

A construction method and strain technology, applied in the field of fermentation and production of high-temperature-resistant xanthan gum, strains and its construction, can solve the problems of high negative mutation ratio, cumbersome processing steps, heavy screening workload, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

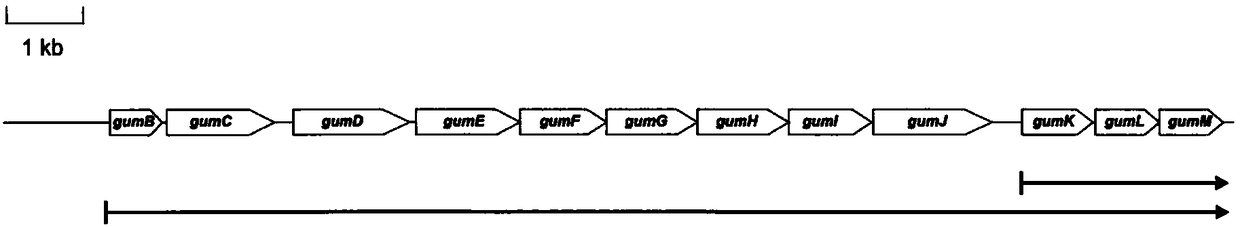

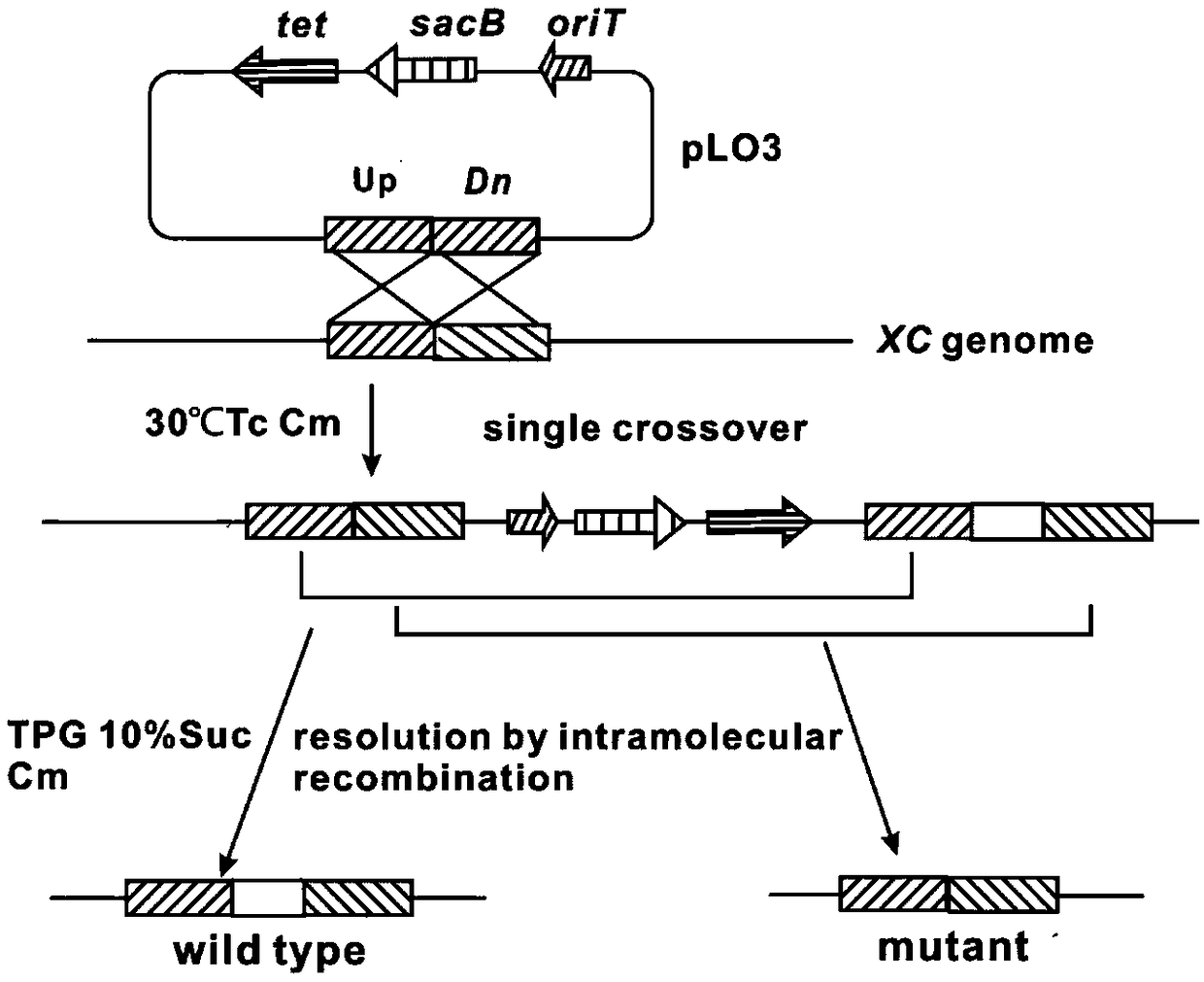

[0094] Embodiment 1: Construction of the knockout plasmid pLO3-gumL:

[0095] Use the extraction kit to extract the genome of XANTHOMONAS CAMPESTRIS WT (strain number NRRL B-1459), the upstream and downstream homology arms of gumL use the genome of XANTHOMONAS CAMPESTRIS WT (strain number NRRL B-1459) as a template, and use primers guml-SF / gumL-SR and gumL-XF / gumL-XR and PrimeSTAR DNA polymerase (Takara Bio, Tokyo, Japan) amplification. The upstream and downstream DNA fragments were connected by overlap PCR, the product was detected by electrophoresis, and the target gene band was purified and recovered by a gel extraction kit to obtain a recombinant fragment. The recombinant fragment and pLO3 plasmid were digested with restriction enzymes SacI and XbaI at the same time, 90min at 37°C, and the digested fragment was purified and recovered by PCR using a kit, and the recovered products of the two were digested with T4 DNA ligase at 16 The recombinant plasmid pLO3-gumL was obta...

Embodiment 2

[0096] Embodiment 2: Construction of expression plasmid pBBR-gumFG:

[0097] Use an extraction kit to extract the genome of XANTHOMONAS CAMPESTRIS WT (strain number NRRL B-1459), use the XC genome as a template, use primers gumFG-F / gumFG-R and PrimeSTAR DNA polymerase to amplify the gumF and gumG genes, and pass the product through Electrophoresis detection, and the target gene band was purified and recovered by a gel recovery kit to obtain the target gene gumFG. The target fragment and the pBBRMCS plasmid were digested with restriction enzymes KpnI and Sma1 at the same time, 90min at 37°C, and the digested fragment was purified and recovered by PCR using a kit, and the recovered products of the two were digested with T4 DNA ligase at 16 The recombinant plasmid pBBR-gumFG was obtained overnight at ℃, and the recombinant plasmid was transferred into E.coli S17 competent cells for amplification of the recombinant plasmid, and single colonies with correct sequencing were picked a...

Embodiment 3

[0098] Embodiment 3: Construction of expression plasmid pMM-gumBC:

[0099] Use an extraction kit to extract the genome of XANTHOMONAS CAMPESTRIS WT (strain number NRRL B-1459), use the XC genome as a template, use primers gumBC-F / gumBC-R and PrimeSTAR DNA polymerase to amplify gumB and gumC genes, and pass the product through Electrophoresis detection, and the target gene bands were purified and recovered by the gel recovery kit to obtain the target genes gumB and gumC. The target fragment and pMMB67eH plasmid were simultaneously digested with restriction enzymes KpnI and XbaI, 37°C, 90min, and the digested fragments were purified and recovered by PCR using a kit, and the recovered products of the two were digested with T4DNA ligase at 16°C After connecting overnight, the recombinant plasmid pMM-gumBC was obtained, and the recombinant plasmid was transferred into E.coli S17 competent cells for amplification of the recombinant plasmid, and a single colony with correct sequenci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com