Method for preparing biological fermentation feed from by-products generated during production of corn starch by wet method

A technology of biologically fermented feed and corn starch, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of poor palatability, single nutrient composition, low digestibility, etc., and achieve the effect of enhancing immunity and stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

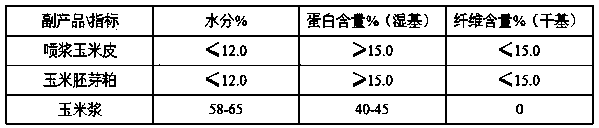

[0017] The method for preparing bio-fermented feed by the by-product of producing cornstarch by wet method comprises the following steps:

[0018] Step 1: Weigh the three raw materials of sprayed corn husk, corn germ meal and corn steep liquor at a mass ratio of 2.4:1.2:1, add 30% sodium hydroxide solution, adjust the pH value of the raw materials to 4.3, and obtain mixture A ;

[0019] Step 2: After adding water to adjust the water content of mixture A to 45%, add 1% of the total amount of the mixture of Bacillus subtilis and Saccharomyces cerevisiae, and mix thoroughly to obtain mixture B;

[0020] Step 3: Put the mixture B in a closed environment at 30° C., and carry out anaerobic fermentation for 96 hours to obtain a biologically fermented feed.

Embodiment 1

[0022] This embodiment discloses the method that utilizes the by-product of wet method to produce cornstarch to prepare biofermentation feed, comprises the following steps:

[0023] Take the preparation of bio-fermented feed with a total amount of about 1 ton as an example:

[0024] Weigh 362.6kg of sprayed corn husks, 181.3kg of corn germ meal, and 151.1kg of corn steep liquor; add 30% sodium hydroxide to adjust the pH value of the material to 4.5 to obtain mixture A, and add water to adjust the moisture content of mixture A to 45 %, finally add a mixture of Bacillus subtilis, Saccharomyces cerevisiae, and lactic acid bacteria that account for 1% of the total amount of materials, mix well and pack them into one-way air intake valve pockets, and place them in an environment of 36°C for no less than 72 hours anaerobic fermentation to obtain biologically fermented feed.

[0025] Further prove the present invention scheme by experiment below:

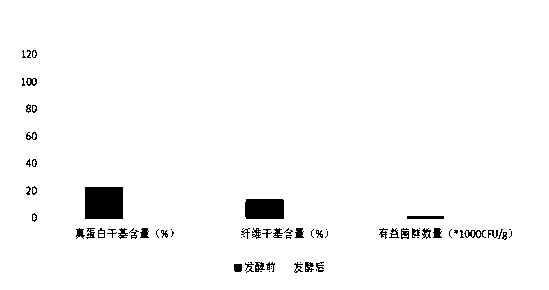

[0026] A large number of experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com