Branching polycarbonate polyhydric alcohol, preparation method and application thereof

A technology of polycarbonate diol and polycarbonate, which is applied in the field of polymers, can solve the problems of shortened solid curing time, weather resistance, high content of low-molecular-weight diols, and wide molecular weight distribution of products, so as to achieve easy control of molecular weight, The effect of high activity and shortened curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

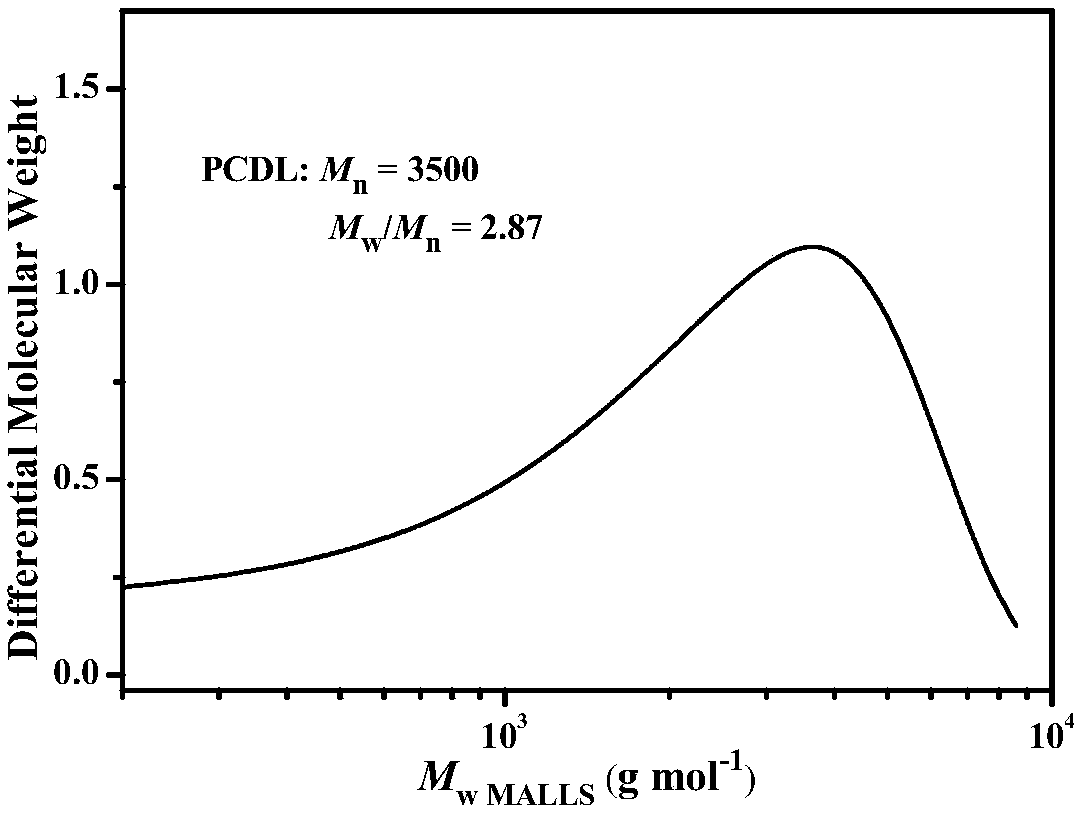

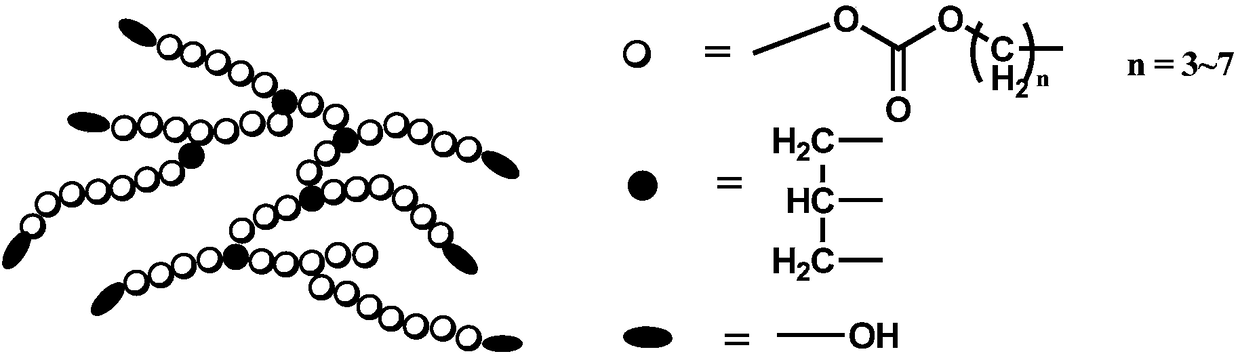

[0036] A branched polycarbonate polyol with a number average molecular weight of 3500, a molecular weight distribution of 2.87 and a hydroxyl value of 128.

[0037] The preparation method of above-mentioned branched polycarbonate polyol may further comprise the steps:

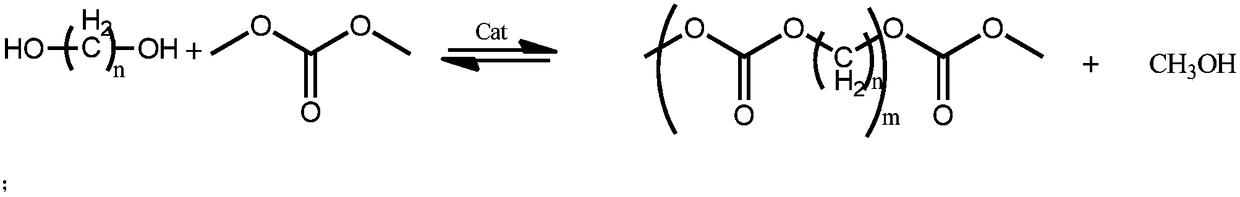

[0038] (1) Synthesis of intermediate low molecular weight polycarbonate containing dimethyl ester

[0039]Butanediol (9.00g, 100mmol) and dimethyl carbonate (18.00g, 200mmol) were added to a 250mL reactor, the temperature was raised to 85°C, oxygen was exhausted during reflux, and then the catalyst pentamethyldiethylenetriamine was placed online (0.00086g, 0.05mmol) was added to the reaction kettle, and the reaction was stirred. The stirred kettle was equipped with a rectification device to separate dimethyl carbonate and methanol. The dimethyl carbonate was refluxed to the reaction to continue to participate in the reaction, and the by-product methanol was removed. Gas chromatography Track the butanediol reac...

Embodiment 2

[0043] A kind of synthesis of branched polycarbonate polyol:

[0044] The difference from Example 1 is that the molecular weight of the intermediate polycarbonate containing dimethyl ester at the end group is 500, the molecular weight of the branched polycarbonate polyol is 4600, the molecular weight distribution is 2.95, and the hydroxyl value is 135.

[0045] Without changing other conditions of Example 1, in step (1), the mass ratio of butanediol (9.00g, 100mmol) and dimethyl carbonate (15.30g, 170mmol) in the preparation process is 1: 1.7, the amount of catalyst is 0.05mmol, and the operation process remains unchanged, and the polycarbonate containing dimethyl ester in the end group is successfully prepared, and the nuclear magnetic calculation molecular weight is 500, and the quality is 18.7g, and the yield is 94.9%; in step (2), Add butanediol (3.9g, 44mmol) and glycerol (1.7g, 18mmol), operation process is constant, the number average molecular weight that draws polymer...

Embodiment 3

[0047] A kind of synthesis of branched polycarbonate polyol:

[0048] The difference from Example 1 is that the molecular weight of the intermediate polycarbonate containing dimethyl ester at the end group is 700, the molecular weight of the branched polycarbonate polyol is 5500, the molecular weight distribution is 3.15, and the hydroxyl value is 140.

[0049] Under the situation of not changing other conditions of Example 1, in step (1), the mass ratio of butanediol (9.00g, 100mmol) and dimethyl carbonate (13.50g, 150mmol) in the preparation process is 1: 1.5, the amount of catalyst is 0.05mmol, the operation process is unchanged, successfully prepared polycarbonate containing dimethyl ester at the end group, the molecular weight is 700, the quality is 14.5g, and the yield is 97.2%; in step (2), add butanediol Alcohol (2.0g, 22mmol) and glycerol (1.7g, 18mmol), operating process is constant, and the number-average molecular weight that draws polymer by gel permeation chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com