Method for removing lead ions in electrolytic copper foil electrolyte

A technology for electrolytic copper foil and copper electrolyte, applied in the electrolysis process, electrolysis components, electroforming and other directions, can solve the problems of accelerated coating passivation failure, anode potential enhancement, current density increase, etc., and achieves low cost and extended use. Time, the effect of reducing the concentration of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

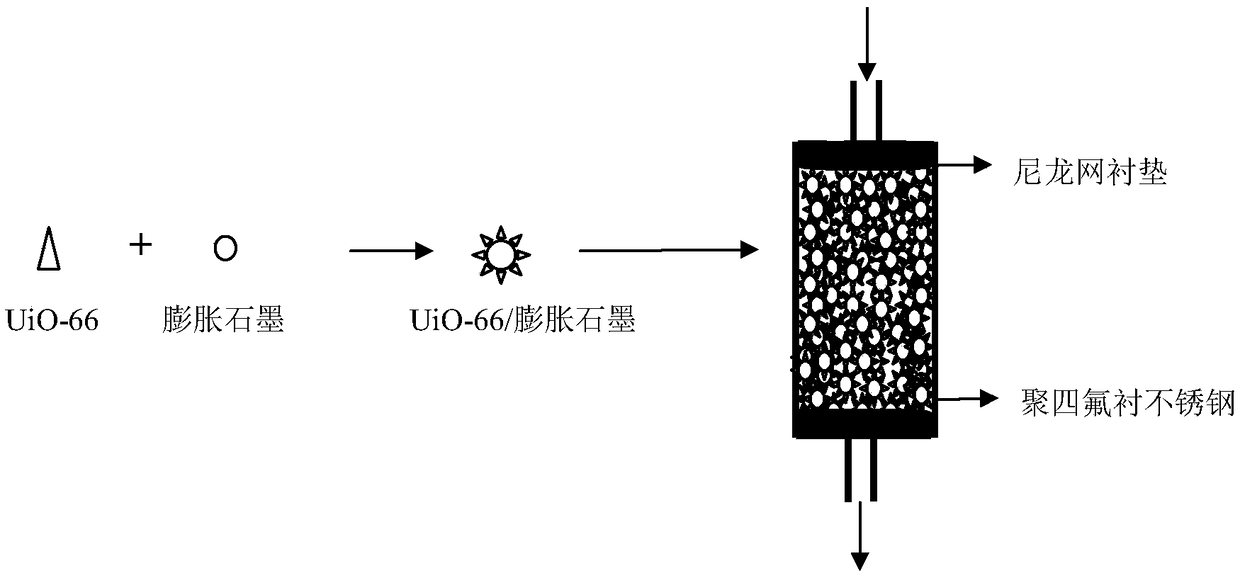

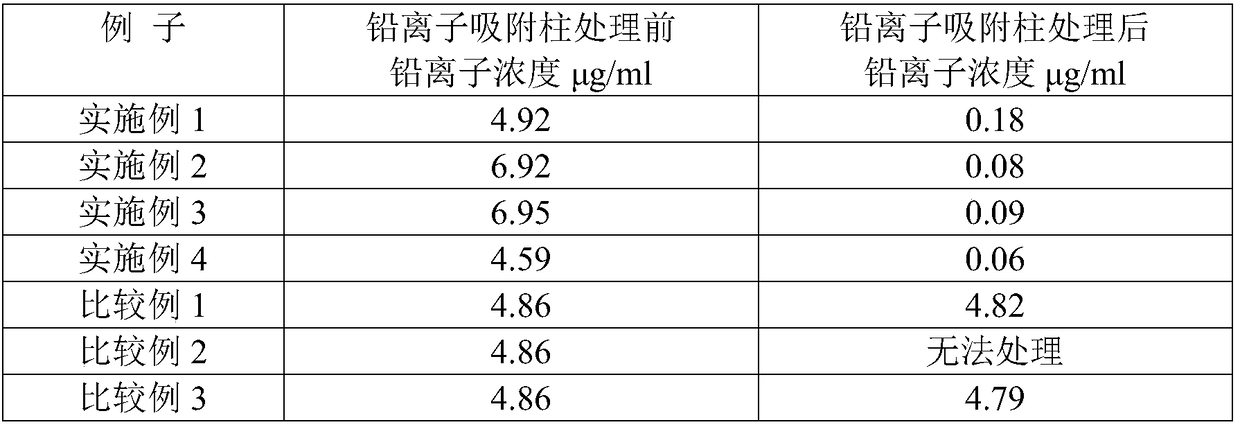

[0018] Take 100g of expanded graphite (EG) and place it in 0.5% (w / w) UiO-66 aqueous solution, after stirring for 3 hours, wash the expanded graphite with deionized water until there is no UiO-66 in the washing solution, then the adsorbed The expanded graphite of UiO-66 is dried and filled into a stainless steel column lined with polytetrafluoroethylene, which is the lead ion adsorption column.

Embodiment 2

[0020] Take 100g of expanded graphite (EG) and place it in a 1.0% (w / w) UiO-66 aqueous solution. After stirring for 3 hours, wash the expanded graphite with deionized water until there is no UiO-66 in the washing solution, and then the adsorbed The expanded graphite of UiO-66 is dried and filled into a stainless steel column lined with polytetrafluoroethylene, which is the lead ion adsorption column.

Embodiment 3

[0022] Take 100g of expanded graphite (EG) and place it in 2.0% (w / w) UiO-66 aqueous solution, after stirring for 3 hours, wash the expanded graphite with deionized water until there is no UiO-66 in the washing solution, then the adsorbed The expanded graphite of UiO-66 is dried and filled into a stainless steel column lined with polytetrafluoroethylene, which is the lead ion adsorption column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com