Micro-bead glass for conductive silver paste and preparation method of micro-bead glass

A technology of microbead glass and conductive silver paste, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of affecting the photoelectric conversion efficiency of solar cells, increasing the series resistance of batteries, and poor printing ink permeability, so as to improve printing stability properties, high surface tension, and high viscosity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

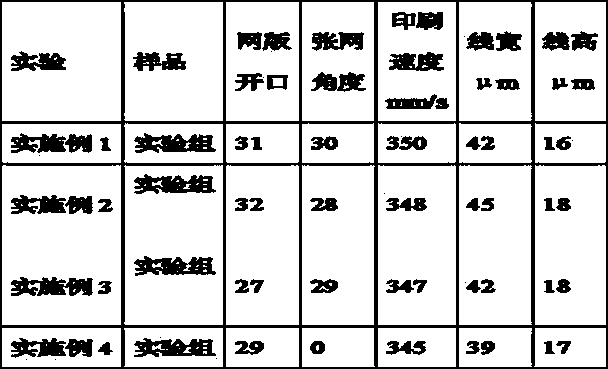

[0037] Embodiment 1~4: a kind of microbead glass for conductive silver paste, described bead glass is made up of the component of following parts by weight, and described glass bead powder is made up of following component:

[0038]

Example 1

Example 2

Example 3

Example 4

tellurium dioxide

12 copies

30 copies

45 copies

24 copies

bismuth oxide

45 copies

30 copies

60 copies

28 copies

Zinc oxide

8 servings

3 copies

5 copies

6 servings

Molybdenum oxide

4 parts

12 copies

6 servings

10 copies

lithium oxide

9 servings

16 copies

6 servings

18 copies

magnesium oxide

1.6 servings

0.6 parts

2 copies

3.2 parts

Aluminum oxide

2 copies

0.5 parts

3 copies

4 parts

1.8 servings

3 copies

2 copies

1 copy

potassium oxide

1.2 parts

0.8 parts

1.6 servings

1.4 par...

Embodiment 1

[0050] In embodiment 1, terpineol, butyl carbitol acetate, oleic acid and polyvinylpyrrolidone are mixed according to a weight ratio of 100:85:25:32 to form a mixed solution; in embodiment 2, terpineol, butyl carbitol acetate , oleic acid and polyvinylpyrrolidone are mixed according to the weight ratio of 100:100:18:20 to form a mixed solution; in embodiment 3, terpineol, butyl carbitol acetate, oleic acid and polyvinylpyrrolidone are according to 100:110:30: 30 weight ratio was mixed to form a mixed liquid; in Example 4, terpineol, butyl carbitol acetate, oleic acid and polyvinylpyrrolidone were mixed according to a weight ratio of 100:90:20:18 to form a mixed liquid.

[0051] Mix the glass microspheres obtained in Examples 1 to 4 with an organic carrier and a dispersant according to a certain ratio, and then add silver powder after three-roll grinding, mix and stir, and make a slurry after three rolls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com